Test device of module

A test device and test stand technology, applied in the system field, can solve the problem of spending a lot of time, no equipment, a few, as many as dozens, or even hundreds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

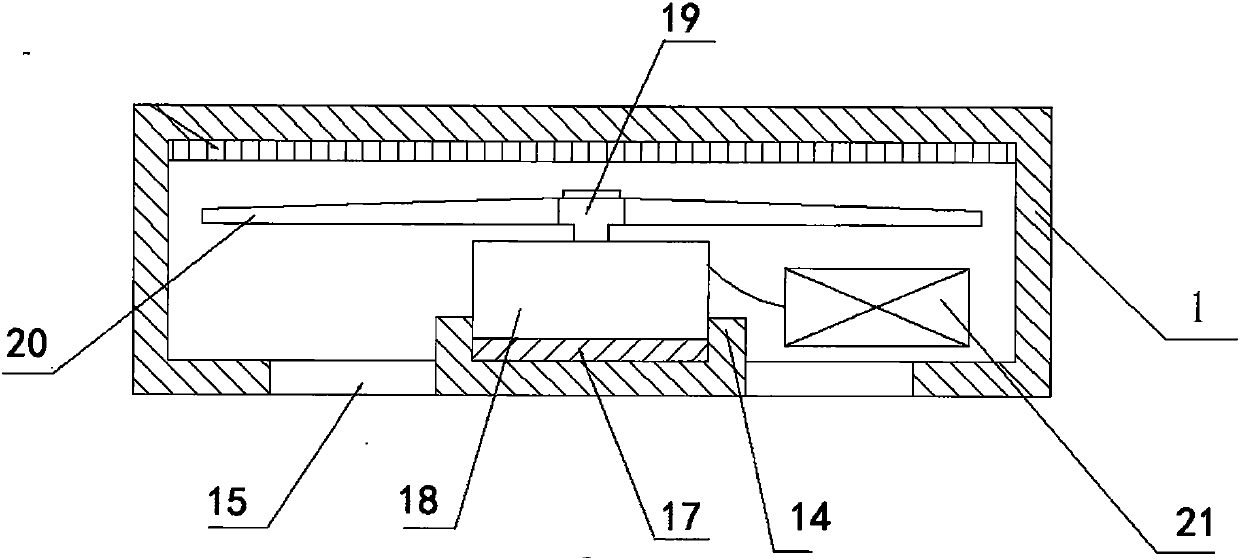

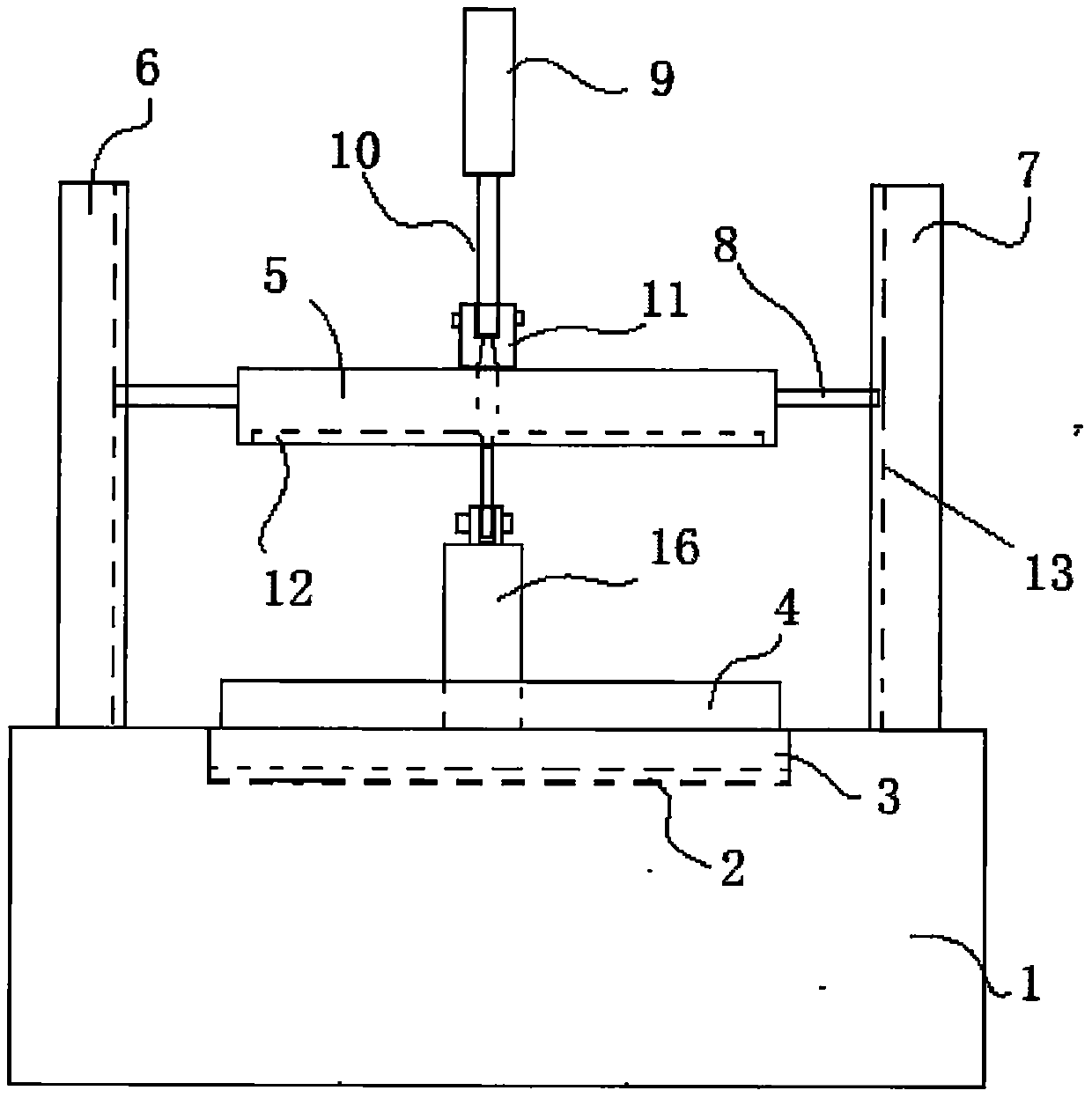

[0015] See Figure 1~2 As shown, a test device for a module includes a test socket 1, a test circuit board 2 matching the module 4 is arranged on the test socket 1, a pressing block 5 is arranged above the test circuit board 2, the The periphery of the pressing surface of the briquetting block 5 has a limit edge 12 matching the shape of the upper end surface of the module shell to form a limit groove, which can cover the upper end of the shell of the module 4. The test seat 1 is provided with a The shape of the bottom end face of the shell of the module is matched with a consistent positioning groove 3, the test circuit board 2 is located in the positioning groove 3, and a heat dissipation system is arranged in the test socket 1, and the heat dissipation system includes The fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com