Tire wear simulation test robot

A robot and tire technology, applied in the field of robots, can solve problems such as difficult to reflect wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

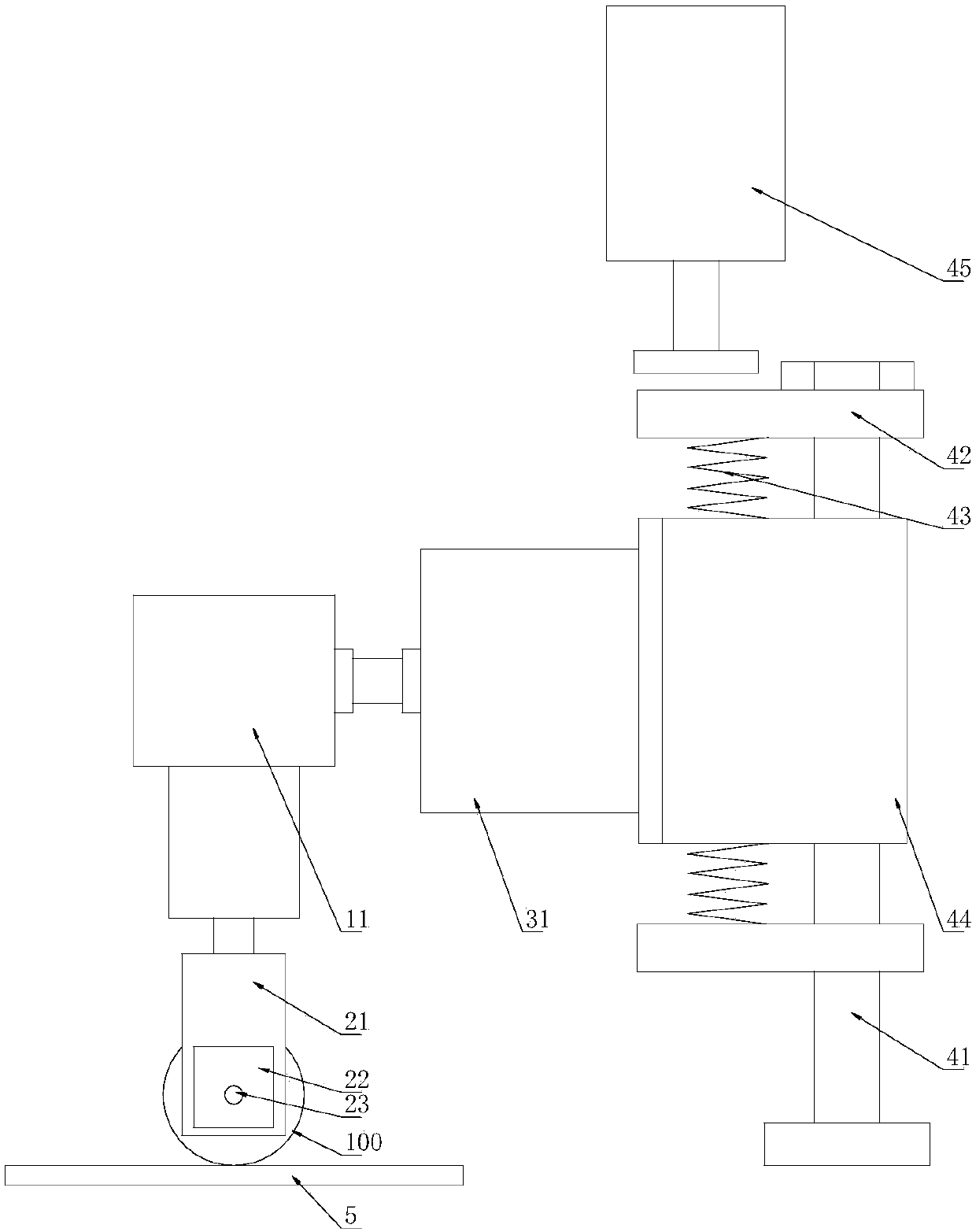

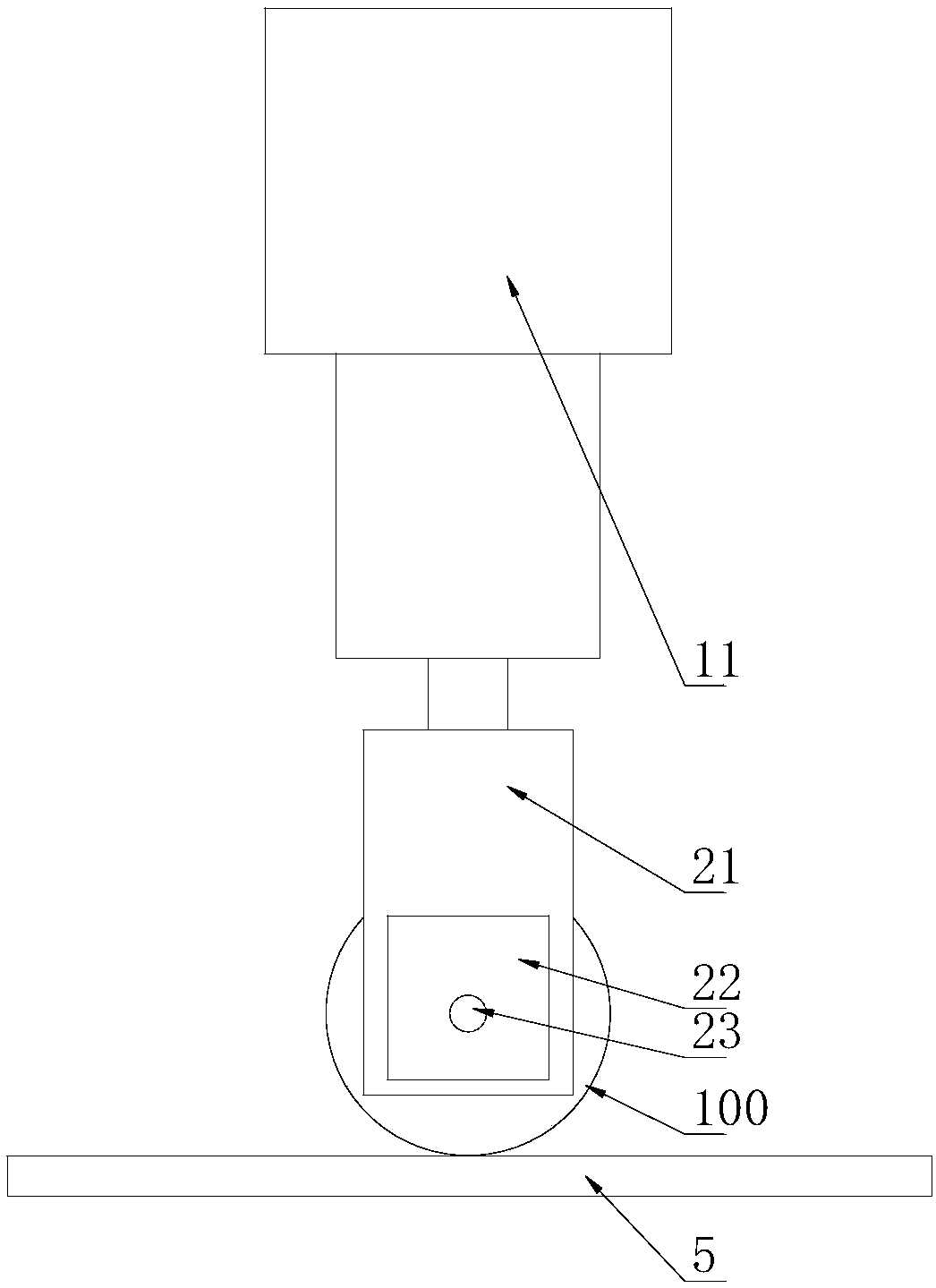

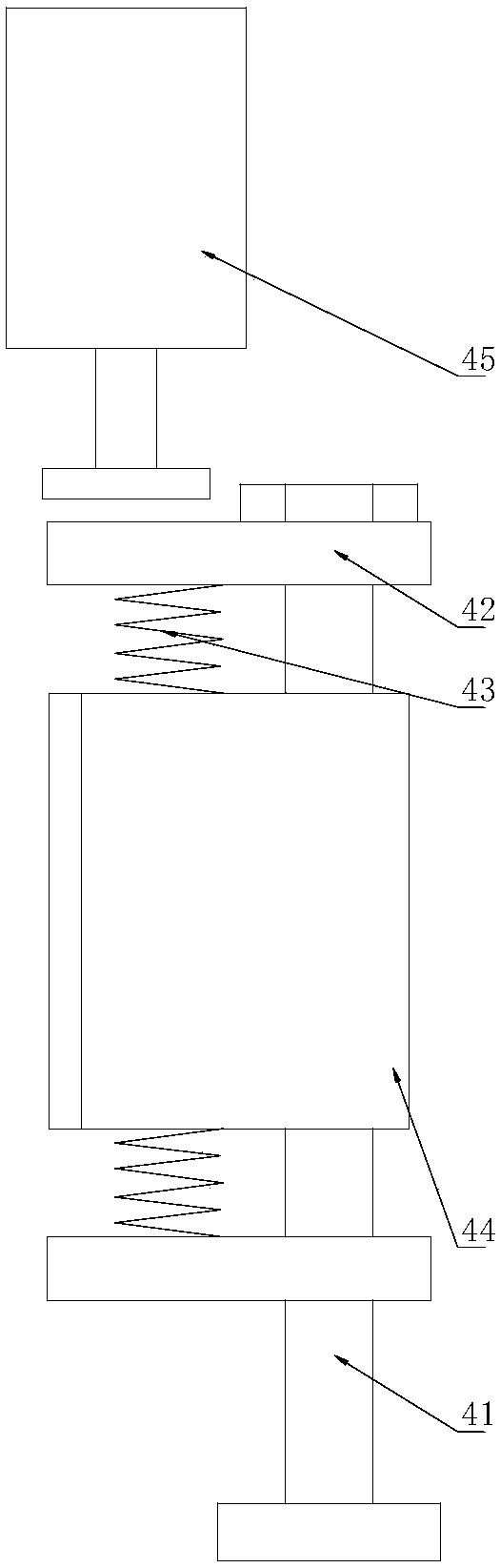

[0015] Attached below Figure 1-3 An embodiment of the present invention is described.

[0016] A robot for simulating tire wear experiments, comprising a steering simulation mechanism, a rotation speed simulation mechanism, an inclination simulation mechanism and a vibration simulation mechanism, the steering simulation mechanism includes a steering reduction motor 11, and the rotation speed simulation mechanism includes a tire suspension 21, a rotating motor 22 and a tire Fixed shaft 23, the tilt simulation mechanism includes a tilt reduction motor 31, the vibration simulation mechanism includes a guide column 41, a spring mounting plate 42 and a high elastic spring 43, the output shaft of the steering reduction motor 11 is connected to the tire suspension 21, and the tire suspension 21 is installed Tire fixed shaft 23, one end of tire fixed shaft 23 is connected to the output shaft of rotating motor 22; Steering reduction motor 11 is installed in the motor housing, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com