A kind of regeneration method of electrode activity of all-vanadium redox flow battery

An all-vanadium redox flow battery and electrode activity technology, which can be used in regenerative fuel cells and other directions, can solve problems such as reduced energy efficiency, reduced voltage efficiency, and increased electrochemical polarization of the battery, so as to extend the service life, reduce maintenance costs, The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

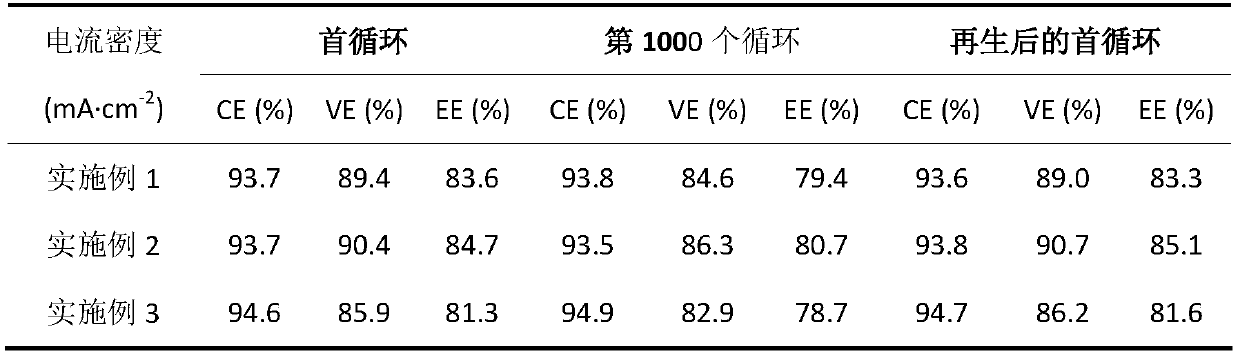

[0019] A full vanadium redox flow battery using carbon felt as an electrode was subjected to a charge-discharge cycle test, and the positive electrolyte was 1.5MVO 2+ 3M H 2 SO 4 Solution 100ml, negative electrode electrolyte is 1.5M V 3+ 3M H 2 SO 4 Solution 100ml. Its at 80mA / cm 2 The initial efficiencies (current efficiency (CE), voltage efficiency (VE) and energy efficiency (EE)) at 1000 and the efficiency at the 1000th cycle are summarized in Table 1. Compared with the first cycle, the voltage efficiency of the all-vanadium redox flow battery in this embodiment decreases from 89.4% to 84.6% at the 1000th cycle, and the energy efficiency drops to 79.4%. Subsequently, stop the charge and discharge cycle of the battery, connect the positive electrode electrolyte inlet and outlet of the battery with the negative electrode electrolyte after the battery cycle, and then connect the negative electrode electrolyte inlet and outlet with the positive electrode electrolyte afte...

Embodiment 2

[0023] A full vanadium redox flow battery using carbon felt as an electrode was subjected to a charge-discharge cycle test, and the positive electrolyte was 1.5MVO 2+ 3M H 2 SO 4 Solution 100ml, negative electrode electrolyte is 1.5M V 3+ 3M H 2 SO 4 Solution 100ml. Its at 80mA / cm 2 The efficiencies of the first cycle and the 1000th cycle are summarized in Table 1. Compared with the first cycle, the voltage efficiency of the all-vanadium redox flow battery in this embodiment decreases from 90.4% to 86.3% at the 1000th cycle, and the energy efficiency drops to 80.7%. Subsequently, the battery was stopped from charging and discharging cycles. Configure 0.5M V 2+ / 1.0M V 3+ 3M H 2 SO 4 Solution 60ml is used as negative electrode electrolyte for regeneration, 1.0M VO 2+ / 0.5M VO 2 + 3M H 2 SO 4 Solution 60ml is used as the positive electrode electrolyte for regeneration, connect the positive electrode electrolyte inlet and outlet of the battery with the negative el...

Embodiment 3

[0025] A vanadium redox flow battery using graphite felt as an electrode was subjected to a charge-discharge cycle test, and the positive electrolyte was 1.5M VO 2+ 3M H 2 SO 4 Solution 100ml, negative electrode electrolyte is 1.5M V 3+ 3M H 2 SO 4 Solution 100ml. Its at 80mA / cm 2 The efficiencies of the first cycle and the 1000th cycle are summarized in Table 1. Compared with the first cycle, the voltage efficiency of the all-vanadium redox flow battery in this embodiment decreases from 85.9% to 82.9% at the 1000th cycle, and the energy efficiency drops to 78.7%. Subsequently, the battery was stopped from charging and discharging cycles. Configure 1.0M V 2+ / 0.5M V 3+ 3M H 2 SO 4 Solution 60ml is used as negative electrode electrolyte for regeneration, 0.5M VO 2+ / 1.0M VO 2 + 3M H 2 SO 4 Solution 60ml is used as the positive electrode electrolyte for regeneration, connect the positive electrode electrolyte inlet and outlet of the battery with the negative elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com