Radiator device combination

A technology for radiators and matching parts, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of increased labor costs and high material costs, and achieve the effects of saving space, saving material costs, and balancing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

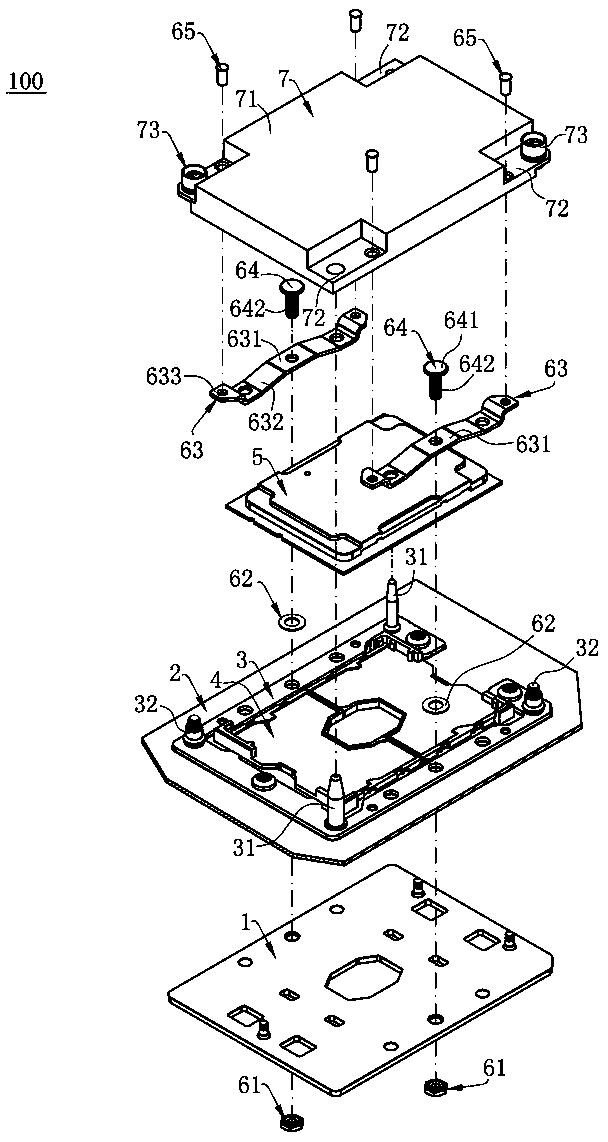

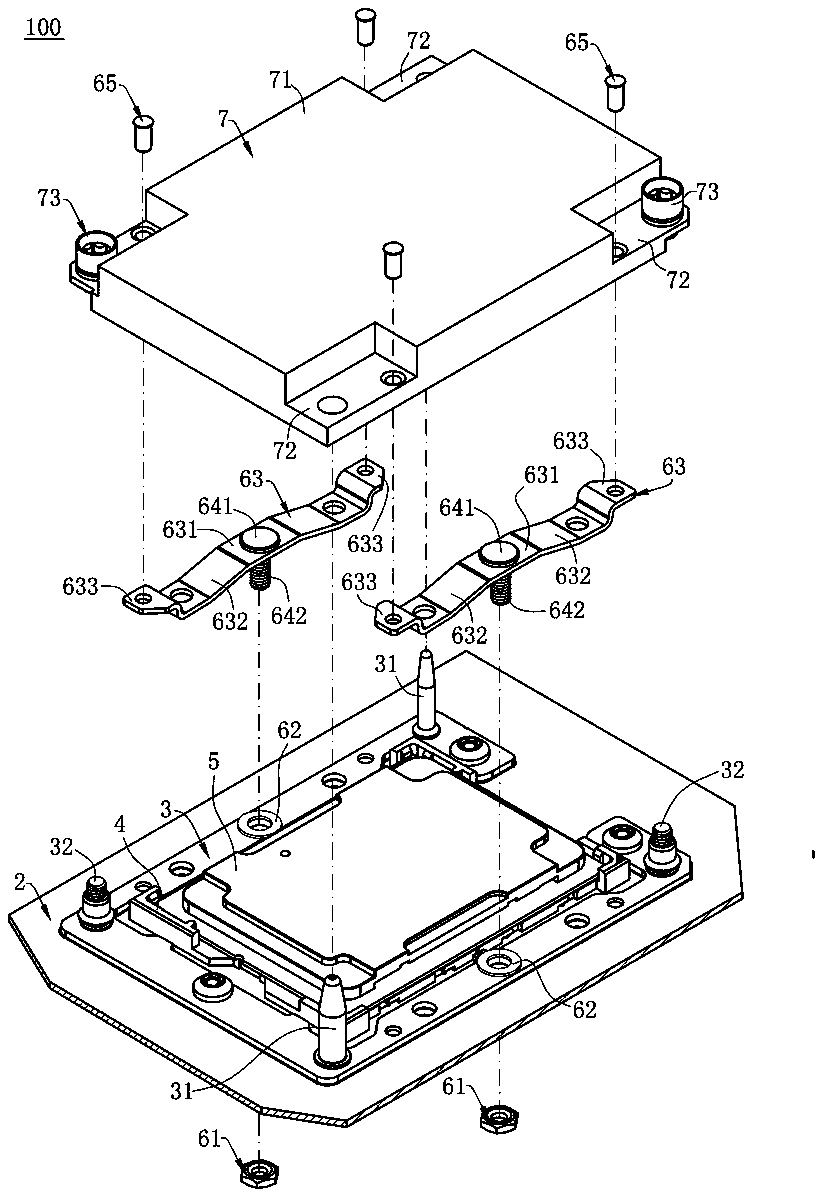

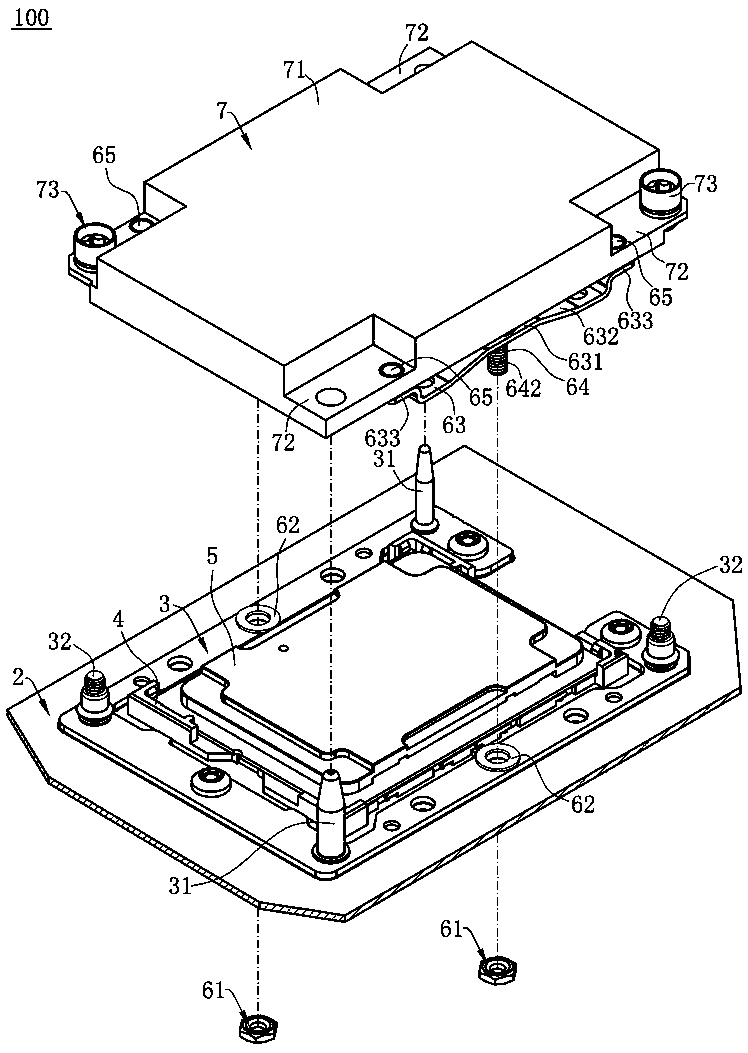

[0028] Such as figure 1 As shown, the radiator device assembly 100 of the present invention mainly includes a metal plate 1, a circuit board 2, a frame body 3, an electrical connector 4, a chip module 5, and two fixing components 6 from bottom to top (auxiliary reference Figure 5 ) and a heat sink 7 .

[0029] Such as figure 1 and figure 2 As shown, the metal plate 1 is arranged below the circuit board 2, and the frame body 3 (made of metal material) is arranged above the circuit board 2 and surrounds the electrical connector 4 The metal plate 1 and the frame body 3 clamp the circuit board 2 up and down together, so that the circuit board 2 is not easy to be bent and deformed.

[0030] Such as image 3 As shown, two guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com