Juice extractor with residue discharge adjusting function

A technology of juice extractor and slag discharge port, which is applied in the field of food processing machines, can solve problems such as unsatisfactory slag discharge effect, influence on juice yield, and juice leakage, and achieve the effects of easy slag discharge, guaranteed juice yield, and avoiding juice leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

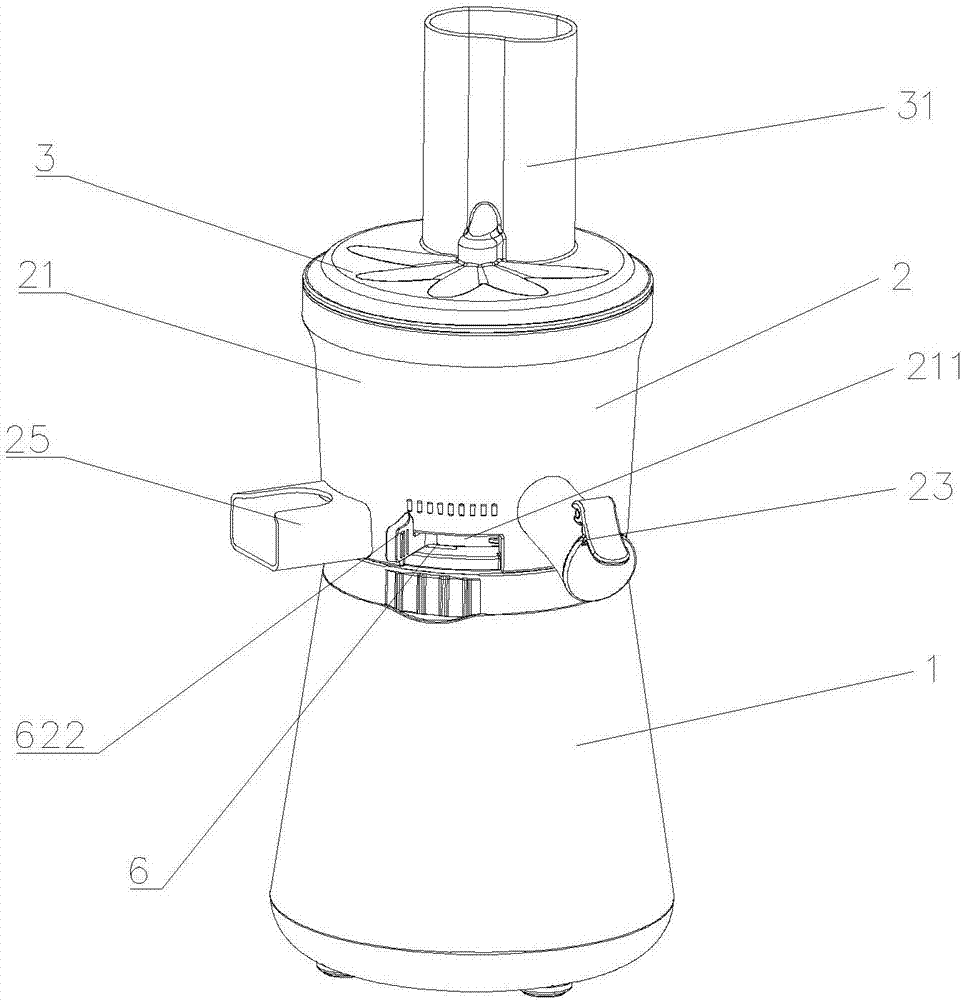

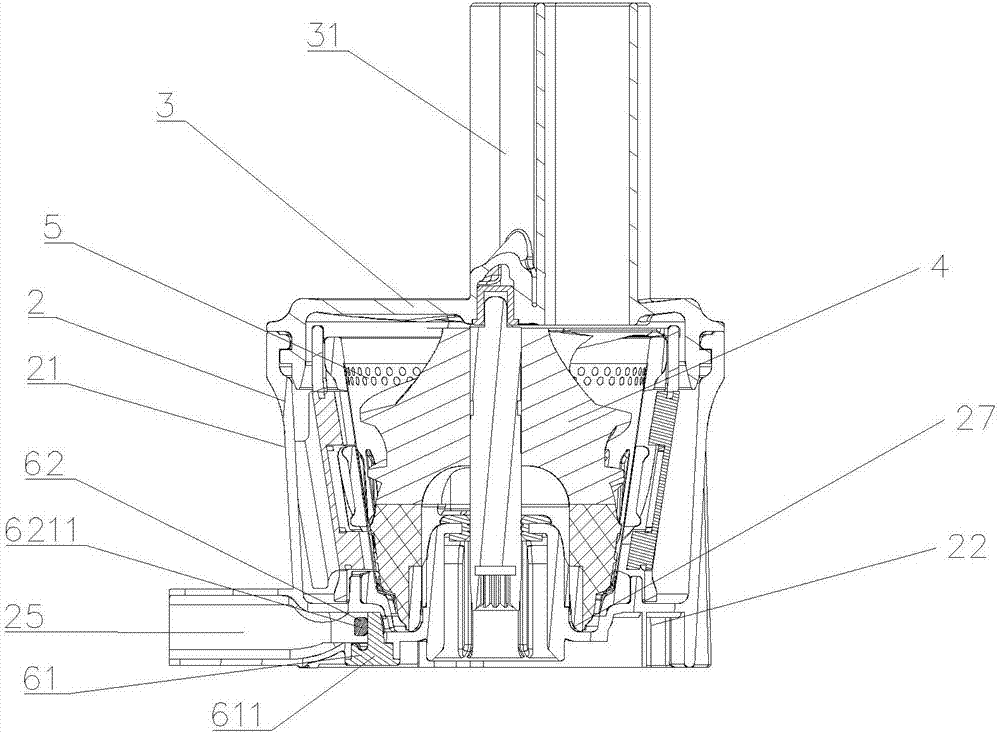

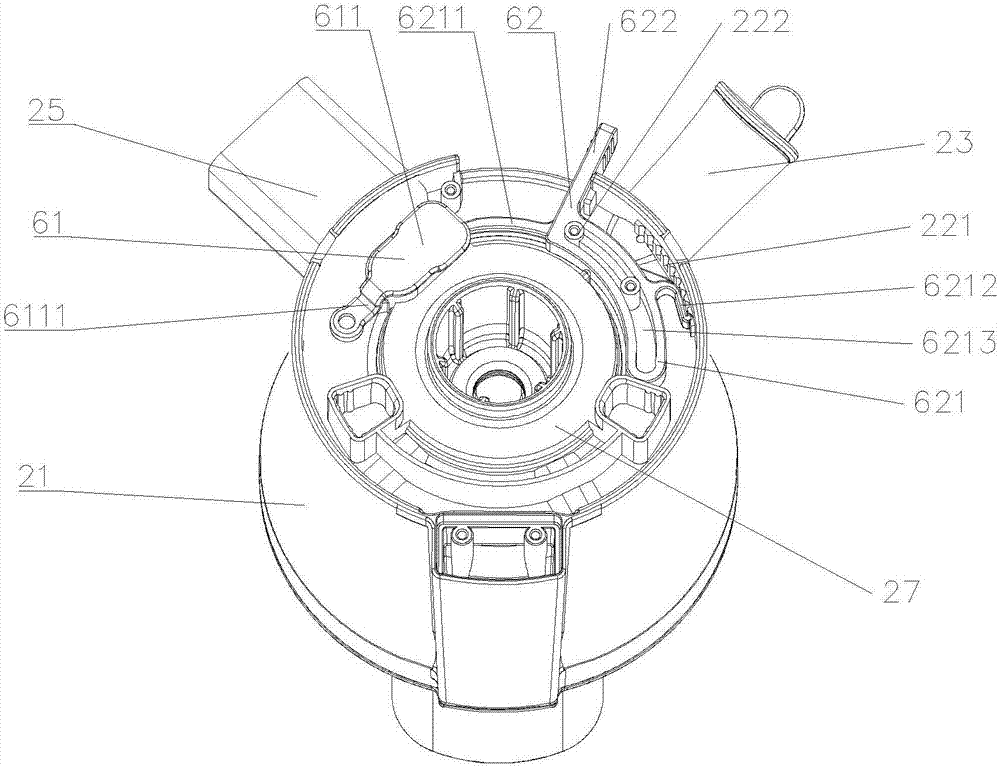

[0044] Such as Figure 1 to Figure 6 As shown, a juice extractor with adjustable slag discharge includes a machine base 1, a motor arranged in the machine base, and a pressing assembly arranged above the machine base. The pressing assembly includes a juice collection chamber 2, which is longitudinally arranged in the juice collection chamber The inner screw 4 is sleeved on the extruding cylinder 5 outside the screw, and is covered with the upper cover 3 above the juice collection chamber. The upper cover 3 is provided with a feed channel 31, and the juice collection chamber includes a side wall 21 and a bottom Wall 22, the center of the bottom wall of the juice collection cavity is provided with a waterproof cylinder 26 with a through hole, and an annular groove 27 is arranged around the waterproof cylinder. The lower end of the screw rod 4 is inserted into the annular groove, and the extruded material The residue is swept into the slag discharge port, the slag discharge port ...

Embodiment 2

[0064] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the flexible sealing part 61 also includes a hard fixing plate 612, and the fixing plate 612 is fixedly connected with the elastic block 611, and the flexible sealing part 61 passes through the The fixing plate 612 is hinged on one side of the opening, and the elastic plug 611 is provided with a mounting groove, and the fixing plate 612 is inserted into the inside of the elastic plug 611 through the mounting groove. On the one hand, the fixing plate 612 is equivalent to a skeleton, which enhances the overall strength of the flexible sealing part 61 and prolongs the service life. On the other hand, the flexible closing part 61 is hinged on one side of the opening through the fixing plate 612, the flexible closing part 61 is easier to cover on the opening 251, and the fixing plate 612 limits the movement track of the flexible closing part 61, so that the flexible closing part 61 R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com