Forging equipment and forging method

A technology for forging and equipment, applied in the field of steel recasting, can solve the problems of huge equipment, low efficiency, and high energy consumption for forging hammer lifting, and achieves the effect of reducing energy consumption, increasing strength, and reducing lifting height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of forging equipment, through the action of gravity and magnetic force to increase the forging strength, and effectively reduce the overall height of the equipment.

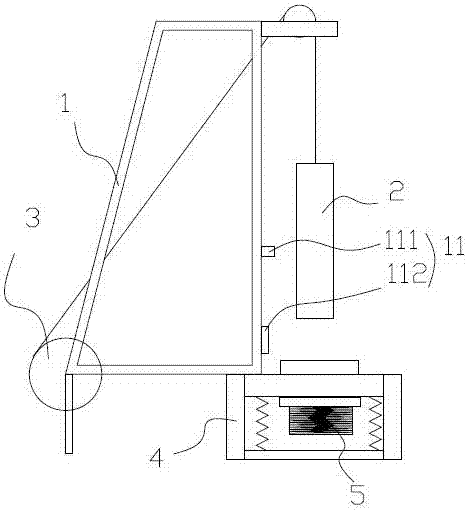

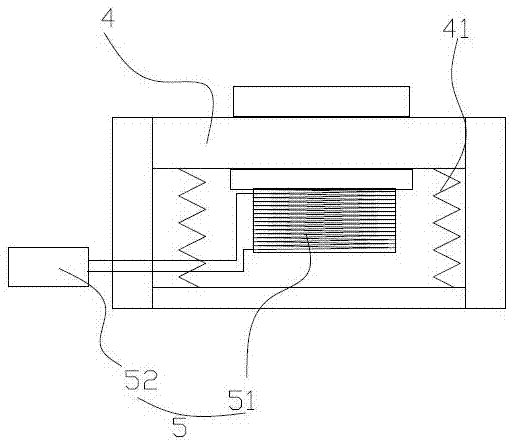

[0025] Specifically, such as figure 1 As shown, including forging frame, forging hammer, driving motor and electromagnetic device.

[0026] Wherein the forging frame is provided with a track for the movement of the forging hammer, the track is placed vertically, and an anvil for forging is provided directly below the track. The forging hammer is set in the track and can move up and down along the forging frame. In order to pull up the forging hammer, the driving motor is also arranged at the bottom of the forging frame, which is connected to the upper end of the forging hammer through a cable. In this embodiment, the top of the forging frame is provided with a fixed pulley, and the cable extends from the motor. It is connected to the top of the forging hammer after bypassing the fixed pulley, and ...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that this embodiment further includes a trigger device, and the control precision of the electromagnetic device is further improved according to the trigger device.

[0031] Specifically, such as figure 1 shown. The forging frame above the forging anvil is provided with an infrared trigger device, which is connected to send an enable signal to the drive circuit, and the trigger device is turned on and off according to the enable signal. In this embodiment, the infrared trigger device includes a first infrared trigger and a second infrared trigger, the first infrared trigger is arranged above the second infrared trigger, the infrared trigger sends a conduction enable signal to the drive circuit, and the second The infrared trigger sends a disconnect enable signal to the drive circuit.

[0032] During the falling process of the forging hammer, the first infrared trigger will be triggered first, and then the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com