Hand-pulling driven cantilever crane with balancing counterweight

A technology for counterweights and cranes, applied to cranes, shafts and bearings, mechanical equipment, etc., can solve the problems of low working level, waste of manpower and material resources, small tonnage, etc., and achieve increased rotation stability and coaxiality, Easy to disassemble and maintain, reduce the effect of fit clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

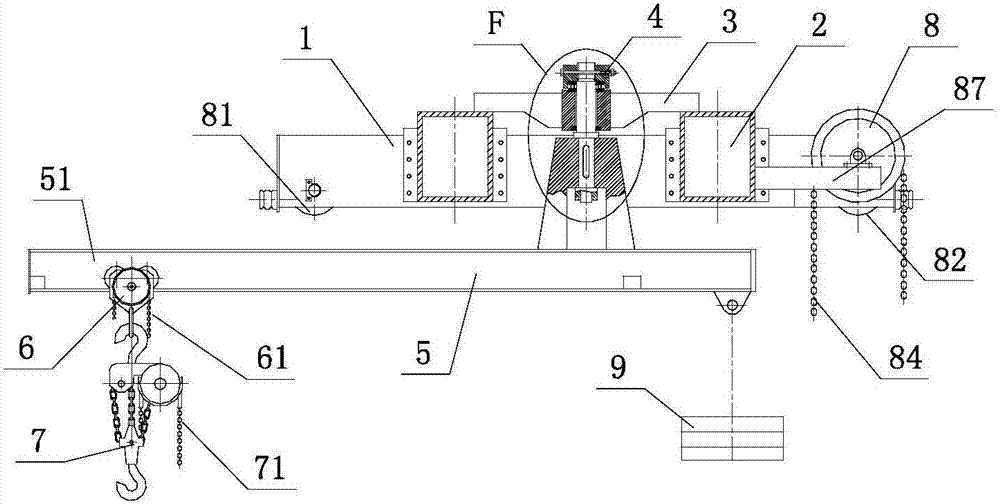

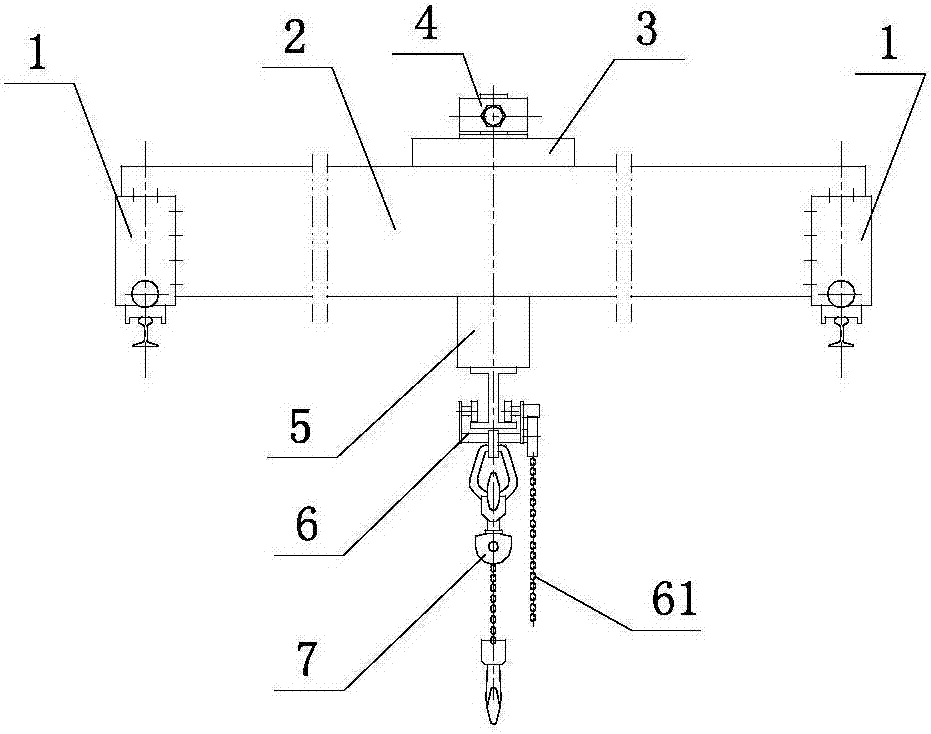

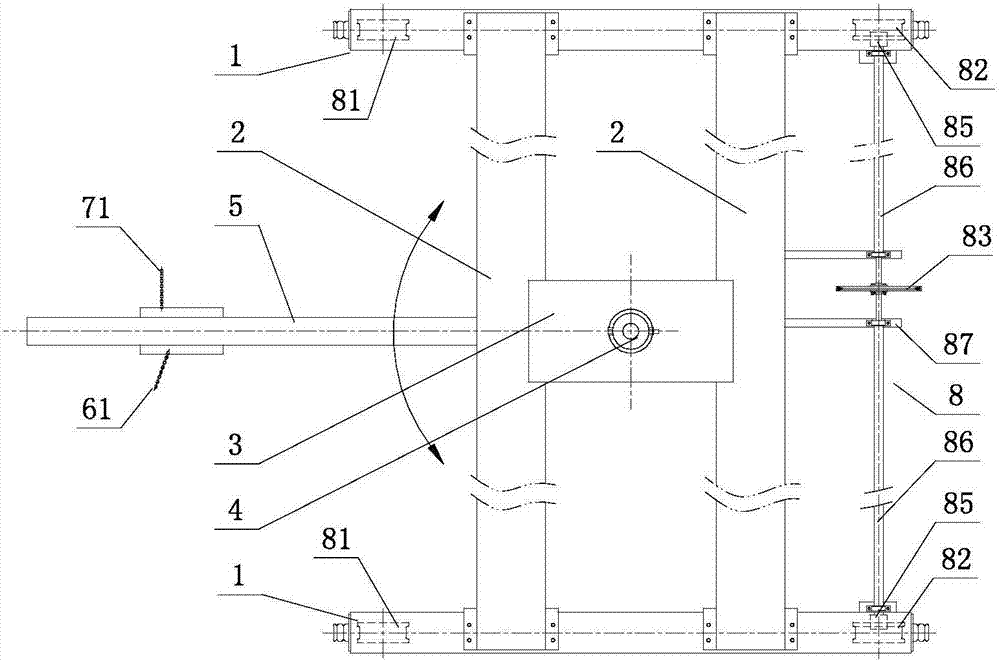

[0022] like figure 1 , figure 2 , image 3 As shown, a cantilever crane with counterweight and hand-pull drive includes two end beams 1 and two main beams 2, which form a double-girder bridge structure; it is characterized in that: between the two end beams A hand-pulled cart running device 8 is provided; a beam platform 3 is fixedly connected above the two main beams 2; a rotating mechanism 4 is arranged on the beam platform; the thrust bearing in the rotating mechanism is connected above the bearing seat and There is a locking nut to fasten; the lower end of the boom shaft in the rotating mechanism is connected to the cantilever member 5; one end of the cantilever beam 51 on the cantilever member is connected to the hand-pulled sports car 6 with a drive chain 61, and the other end is suspended for balance The heavy hammer 9 overturns; the hand-pulled sports car can move back and forth horizontally along the cantilever beam; the hand-pulled chain hoist 7 suspended under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com