Vapor deposition apparatus and evaporation source

An evaporation source and evaporation technology, which is applied in the directions of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problem of blockage of the opening of the evaporation mouth, and achieve the effect of preventing reflection or re-evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

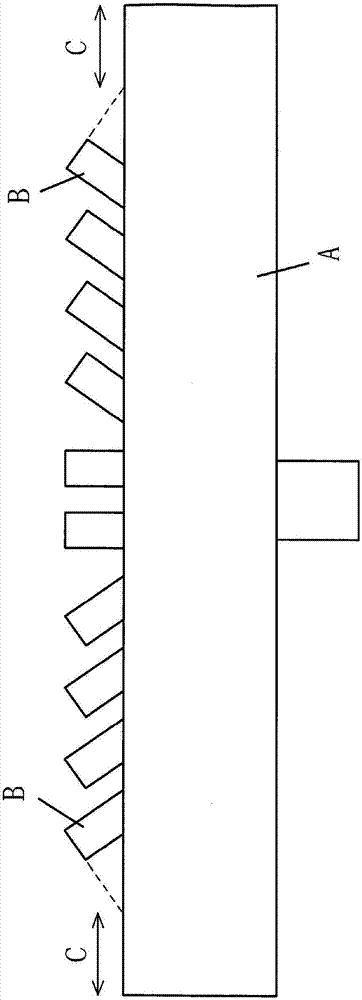

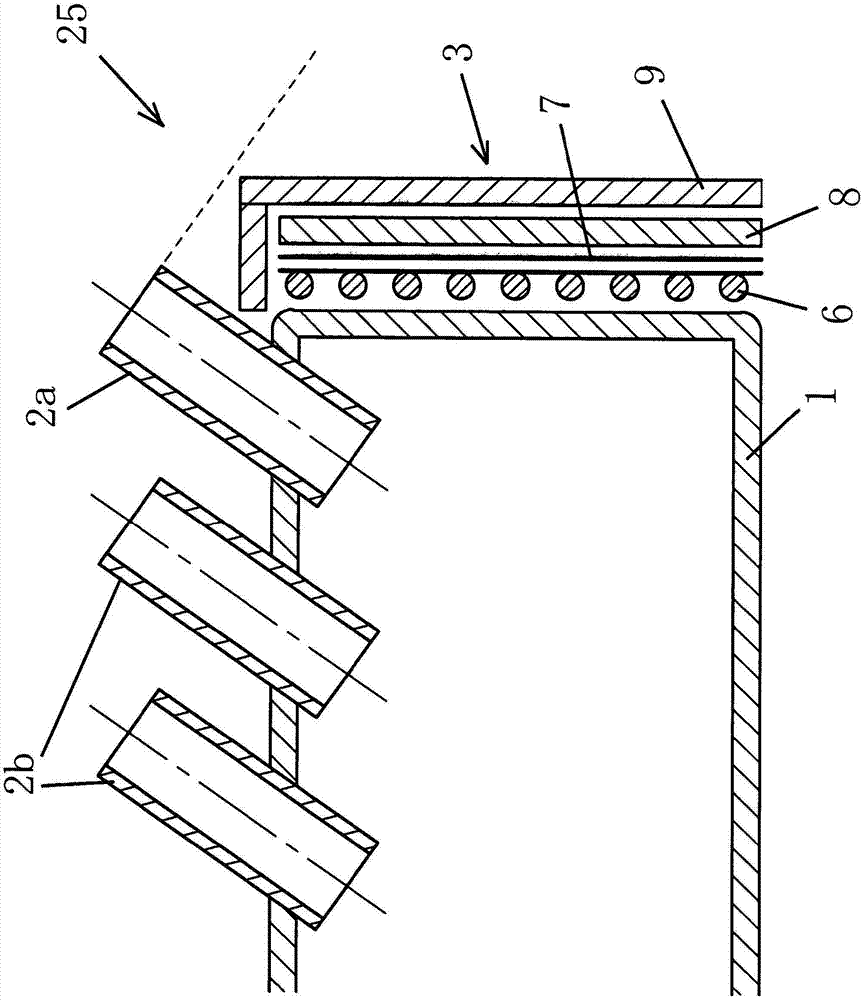

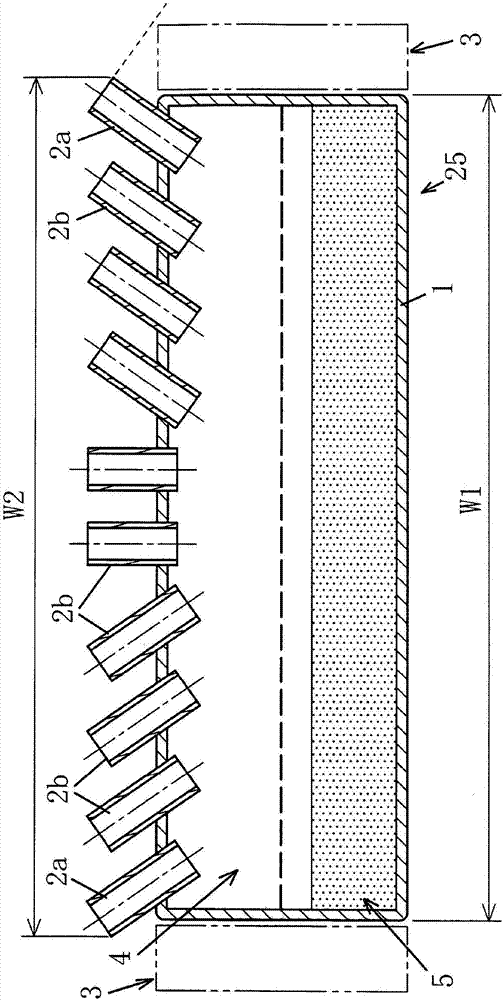

[0033] The action of the present invention is shown based on the drawings, and the preferred embodiments of the present invention are briefly described.

[0034] The evaporated film-forming material is released from the evaporation ports 2a and 2b of the container 1 to form a vapor-deposited film on the substrate.

[0035] At this time, the evaporation source surrounding members 3 such as the container 1 and the heating member and the cooling member do not protrude outward from a virtual plane including the opening end surface of the outer evaporation port portion 2a, that is, they do not protrude outward from the opening end surface of the outer evaporation port portion 2a. There are no container 1 and evaporation source peripheral member 3 in the region affected by the discharged film-forming material, so reflection to the container 1 or re-evaporation of the film-forming material discharged from the opening end surface of the outer evaporation port 2a and to the evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com