Section steel reinforced concrete beam column framework joint and joint construction method

A technology of beam-column joints and construction methods, which is applied in the direction of architecture and building construction, can solve problems such as difficulty in ensuring installation quality, low installation efficiency, and poor structural performance, and achieve improved bearing capacity, precise interconnection positional relationship, and structural good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

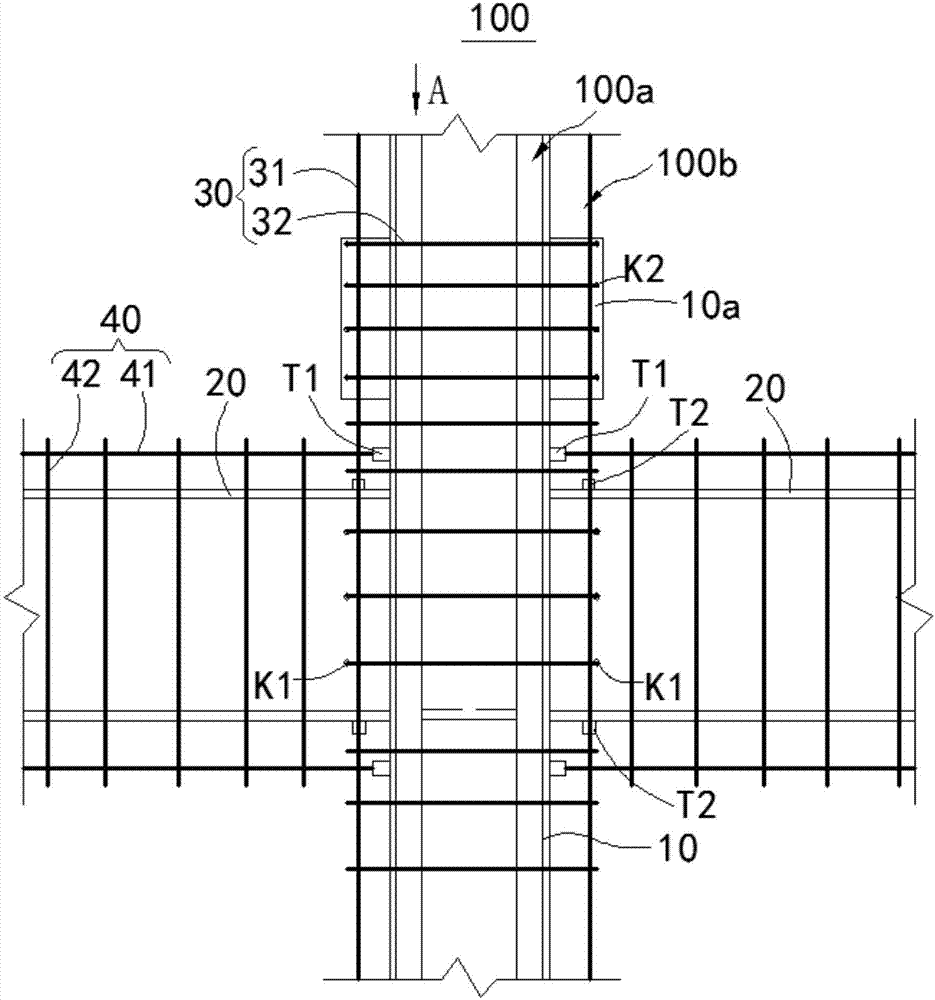

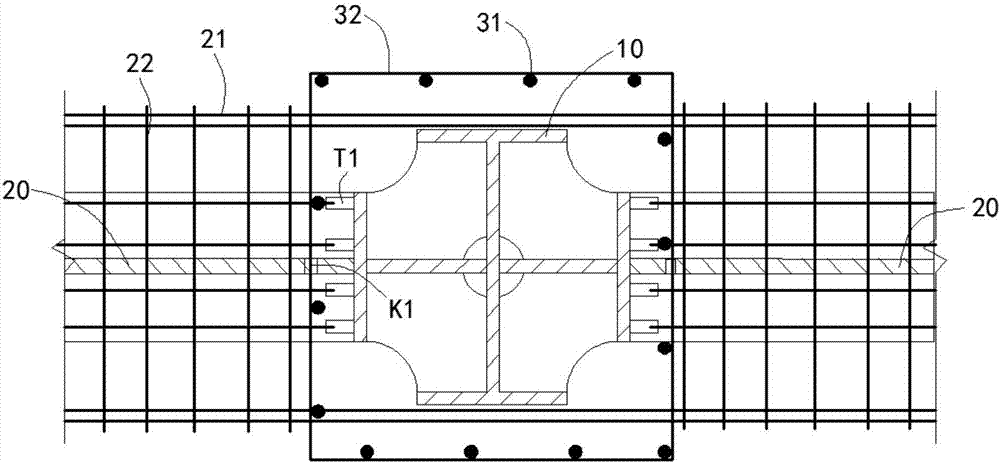

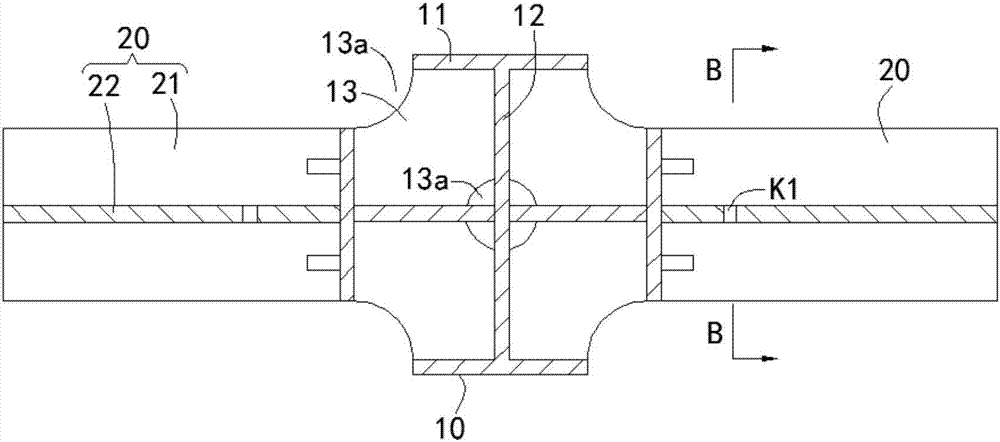

[0049] figure 1 It is a structural schematic diagram of the steel concrete beam-column skeleton node 100 in the embodiment of the present invention. figure 2 for figure 1 A view from direction A. Please refer to figure 1 , figure 2, the steel concrete beam-column skeleton node 100 in this embodiment includes a steel concrete beam-column skeleton node 100 including a steel structure 100a and a steel bar structure 100b. On the whole, the shaped steel structure 100a is inside, and the steel bar structure 100b surrounds the shaped steel structure 100a, and has a certain connection relationship with the shaped steel structure 100a.

[0050] The shaped steel structure 100a includes shaped steel columns 10 and shaped steel beams 20 respectively connected to both sides of the shaped steel columns 10 (see image 3 ), the reinforcement structure 100b includes a column reinforcement cage 30 composed of a column main reinforcement 31 and a column stirrup 32, and a beam reinforcemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com