Electric transmission device of split helicopter tail inclined beam pin locking mechanism and pin locking mode

A transmission device and helicopter technology, applied in transmission devices, motor vehicles, gyrocopters, etc., can solve the problems of optimization, manual manual unlocking, and the locking force cannot be too large, and achieve the effect of reducing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

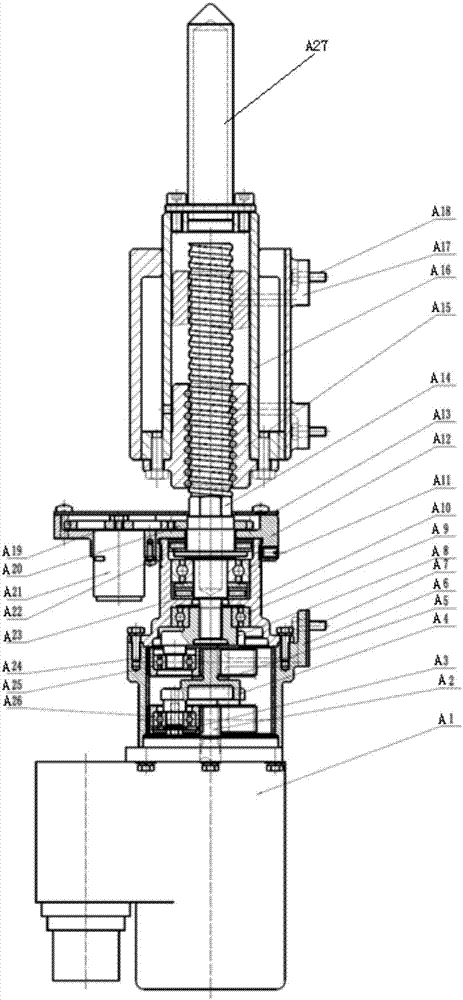

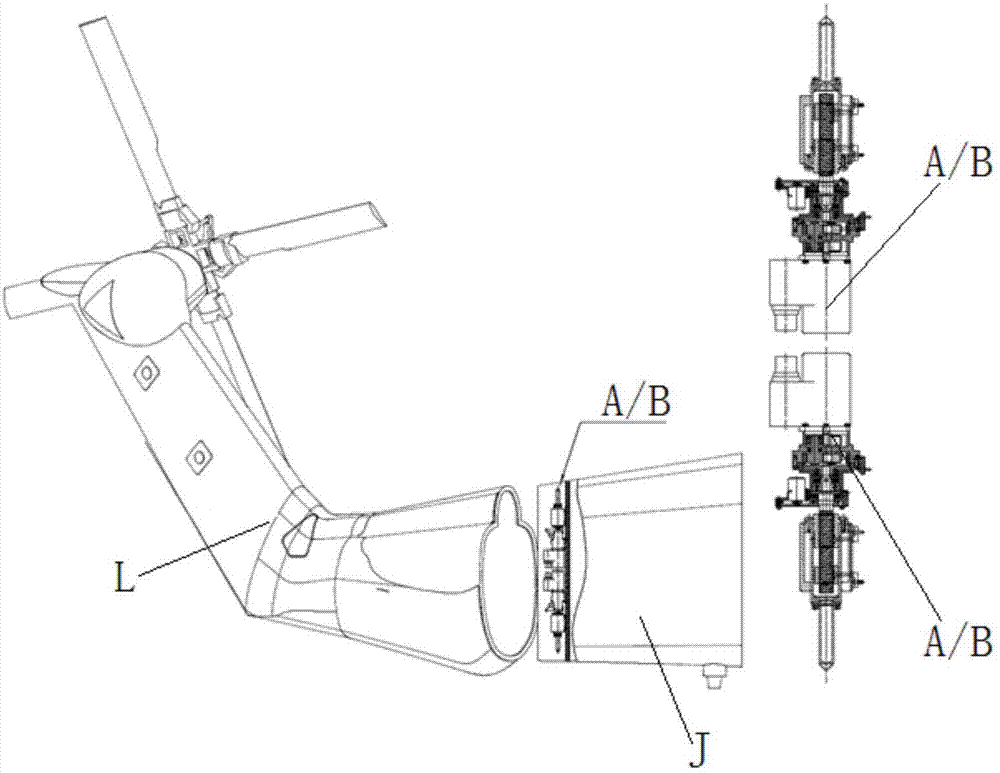

[0037] see figure 1 , a split-type helicopter tail beam locking mechanism electric transmission device, is characterized in that: comprise upper and lower two sets of locking systems A installed on the fuselage J. The locking pins A27 of the two sets of locking pin systems A are retractable, and are used for locking the foldable tail beam L of the helicopter.

[0038] A lock pin system A mainly includes a drive motor A1, a gear transmission reduction pair and a ball screw transmission pair.

[0039] The gear transmission reduction pair includes a two-stage planetary gear train:

[0040] The first-stage planetary gear train is composed of sun gear IA2, ring gear A6, several planetary gears IA3, several deep groove ball bearings IA26 and planet carrier IA4.

[0041] The lower end of the inner ring gear IA6 is fixedly connected with the casing of the drive motor A1 through bolts. The motor output shaft A2 of the driving motor A1 extends into the ring gear IA6, and the upper en...

Embodiment 2

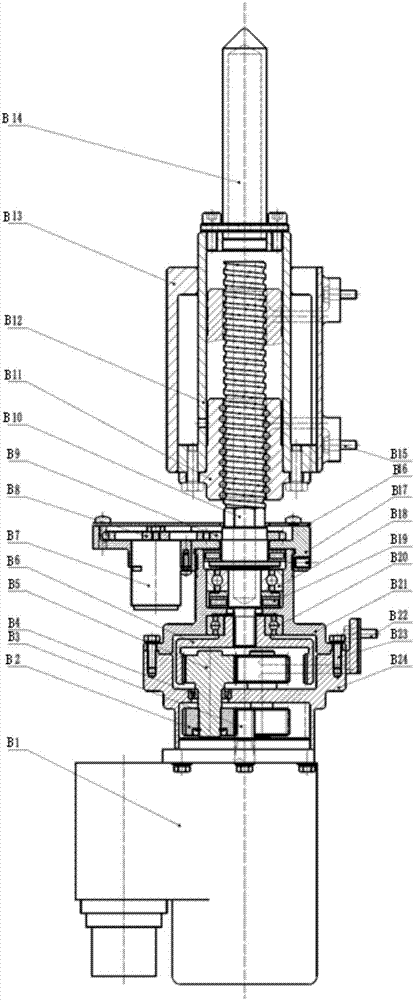

[0047] see figure 2 , a split type helicopter tail beam lock pin mechanism electric transmission device, it is characterized in that: comprise upper and lower two sets of lock pin systems B installed on fuselage J. The locking pins B14 of the two sets of locking pin systems B are retractable, and are used for locking the foldable tail beam L of the helicopter.

[0048] A lock pin system B mainly includes a star gear train and a box

[0049] Described box body is made up of upper box body B21 and lower box body B24. The star gear train is installed inside the box.

[0050] The external meshing transmission of the star gear train is composed of a sun gear IB3 and several planetary gears IB2. The internal meshing of the star gear train is composed of the ring gear IIB6 and several planetary gears IIB5. Each of said planetary gears IB2 is coaxial with a planetary gear IIB5. The coaxially connected planetary gear IB2 and planetary gear IIB5 rotate with the shaft, and their ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com