Pulse-type steam generating system

A generation system, pulsed technology, applied in the direction of steam generation, steam generation method, control system, etc., can solve the problems of reducing the safety factor of appliances, poor steam stability, waste of heat energy, etc., to improve work efficiency and product quality, improve effective Effectiveness of utilization and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

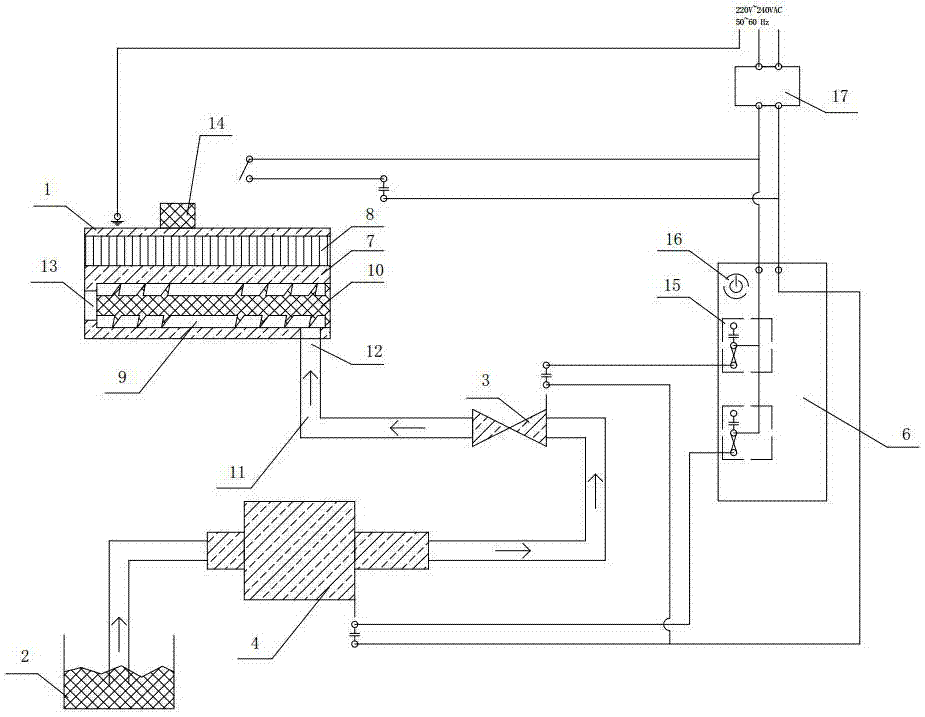

[0012] A pulse type steam generation system described in Example 1, such as figure 1 As shown, it includes a heating metal body 1, a cut-off and pressure relief device 3 connected with the heating metal body, a water pump 4 connected with the cut-off and pressure relief device, and also includes three parts connected and controlled respectively with the heating metal body, the cut-off and pressure relief device and the water pump. The integrated control circuit board 6 that operates independently, the integrated control circuit board controls the water pump to pump water into the heating metal body in a pulsed manner, and the water pump is connected to the water source 2; the heating metal body includes a metal body 7, a heating tube 8 located in the metal body , the cavity 9 which is set in the metal body and separated from the heating pipe, the water guide pipeline 10 which is set in the cavity and has a gap space with the cavity, and the interception and pressure relief devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com