Small-size high-speed dispersion machine for laboratory

A technology for high-speed dispersing machines and laboratories. It is applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc. It can solve problems such as poor safety, shaking or even dumping of the material cylinder, and easy falling of the motor. Achieve good mixing effect, easy to clean, and prevent accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

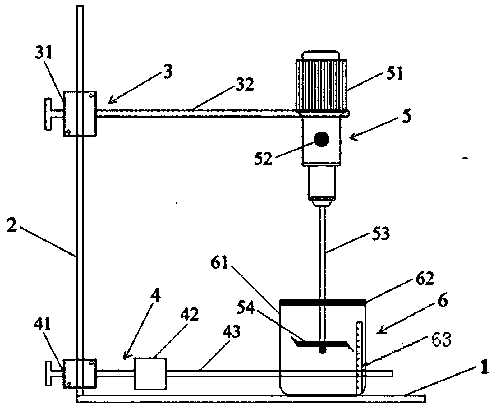

[0027] Such as figure 1 As shown, a small-scale high-speed dispersing machine for a laboratory includes a base 1 and a support rod 2, the support rod 2 is fixed on the base 1, and a lifting frame 3 that can move up and down is installed on it, and the end of the lifting frame 3 The part is fixedly connected with the stirrer 5, and also includes a fixer 4 for fixing the material cylinder 6, and the fixer 4 is connected with the support rod 2.

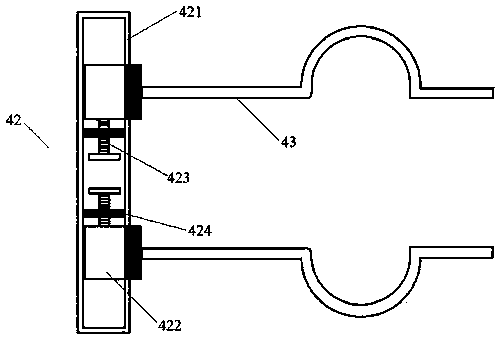

[0028] Such as figure 1 and 2 As shown, the fixer 4 includes a first movable valve 41, a fixed clip regulator 42 and a fixed clip 43 that are fixedly connected in sequence. The first movable valve 41 is connected to the support rod 2, and the fixed clip adjusts The device 42 includes a sliding groove 421, a fixed piece 424, a sliding block 422 and an adjustment knob 423, the fixed piece 424 is fixed on the sliding groove 421, the sliding block 422 is embedded in the sliding groove 421 and one side thereof is connected with the fixing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com