A Method and Device Based on Friction Stir Bonding-Microdroplet Composite Additive Manufacturing

A technology of friction stir and additive manufacturing, which is applied in the field of metal material manufacturing, can solve problems such as deformation fusion, defects, and cracks, and achieve the effects of improved bonding performance, small thermal deformation, and simple processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

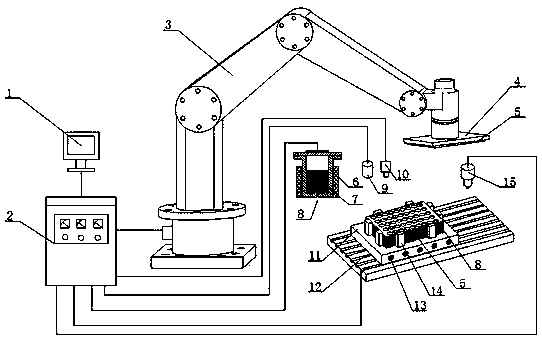

[0031] Such as figure 1 shown.

[0032] A method based on friction stir bonding-microdroplet composite additive manufacturing, the specific steps are as follows:

[0033] (1) According to the three-dimensional model of the required additive manufacturing parts, the parts are divided into several layers by slicing method, from bottom to top, respectively recorded as the 1st, 2nd, 3rd, ..., n layers, among which the odd numbered layers Metal sheets are used, and the even-numbered layers are made of micro-droplet layers for additive manufacturing. The first layer of metal sheets 5 is placed on the substrate 11, and the fixture system is started to fix the first layer of metal sheets 5. The substrate 11 is fixed on the five-axis by bolts. On the CNC workbench 12.

[0034] (2) Control the temperature of the micro-droplet injection system 6 through the computer 1 to melt the metal into molten metal 7, start the auxiliary heating device 13 and the ultrasonic vibration device 10, an...

Embodiment 2

[0038] Such as figure 1 shown.

[0039] A friction stir bonding-microdroplet composite additive manufacturing device includes a control system, a fixture system, a metal sheet conveying system, a microdroplet injection system, and a friction stir bonding system. Such as figure 1 As shown, the control system is composed of a computer 1 and a controller 2; the fixture system is composed of a base plate 11, an ultrasonic vibration device 10, an auxiliary heating device 13 and a plurality of clamps 14; the sheet metal conveying system is composed of The mechanical arm 3, the adsorption device 4 and the positioning device 9 are composed of the micro-droplet injection system, which is composed of the micro-droplet injection device 6, the molten metal 7 and the micro-droplet 8; The CNC workbench 12 and the horizontal friction stir device 15 are composed. The ultrasonic vibration device 10 is located directly above the substrate, and its spatial position can be controlled by the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com