Automated load handling for industrial vehicle

A vehicle and handling system technology, applied to motor vehicles, trolleys, trolley accessories, etc., can solve problems affecting the effectiveness of vehicles or pedestrians

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

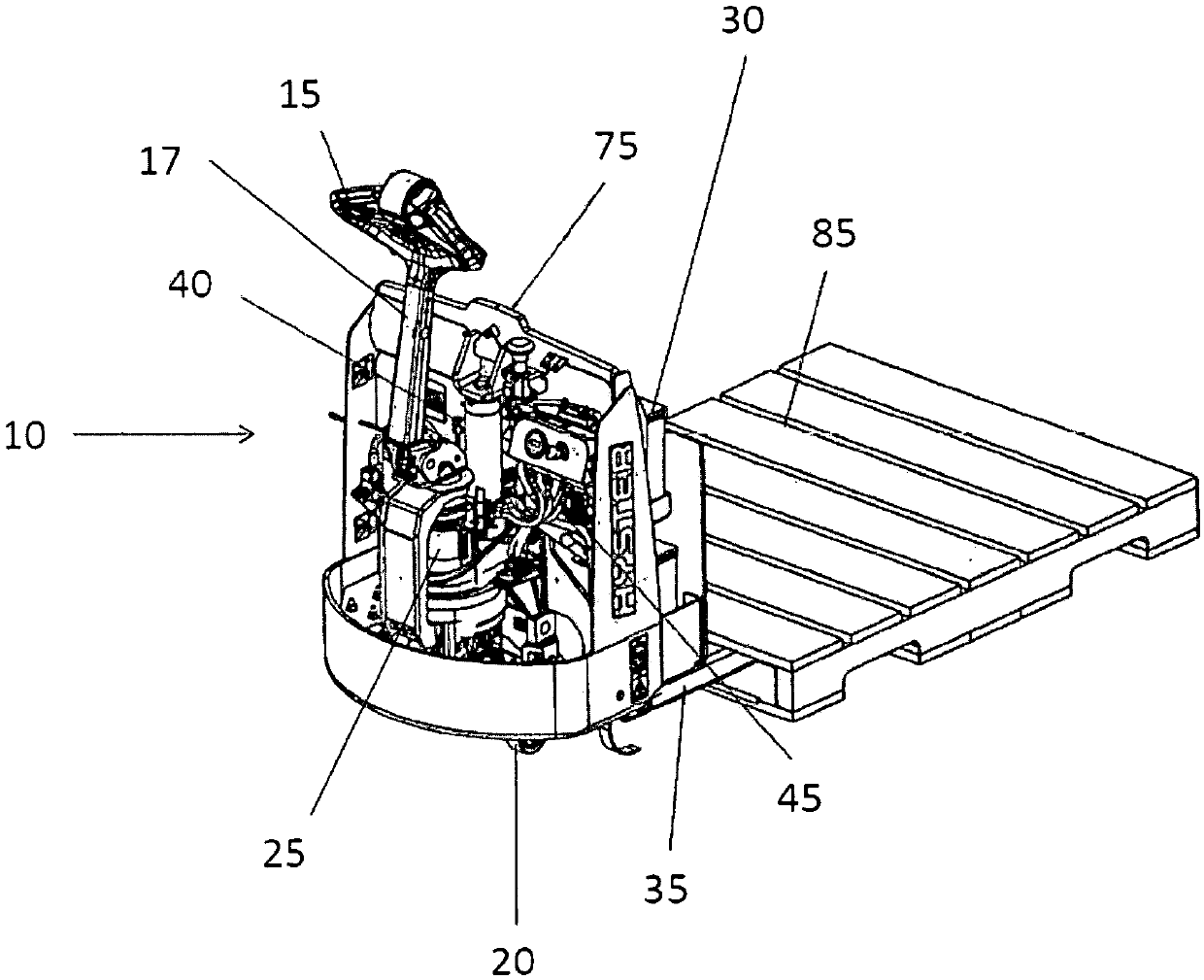

[0034] figure 1 A right front isometric view of the exemplary pallet jack 10 with its lid removed is illustrated. The pallet jack 10 may be referred to as a "stand-off" type pallet jack. The pallet jack 10 includes a control handle 15 attached to a steering arm 17 that can be rotated to cause rotation of the drive wheels 20 to control the direction of travel of the pallet jack 10 . The pallet jack 10 is moved by a traction motor 25 which is energized by a battery 30 . A pair of forks 35 can be raised and lowered via hydraulic cylinders 40 . Electronic controller 45 communicates with the lift, lower, and traction actuators and effects activation of traction motor 25 and hydraulic cylinders 40 in response to commands received from the lift, lower, and traction actuators.

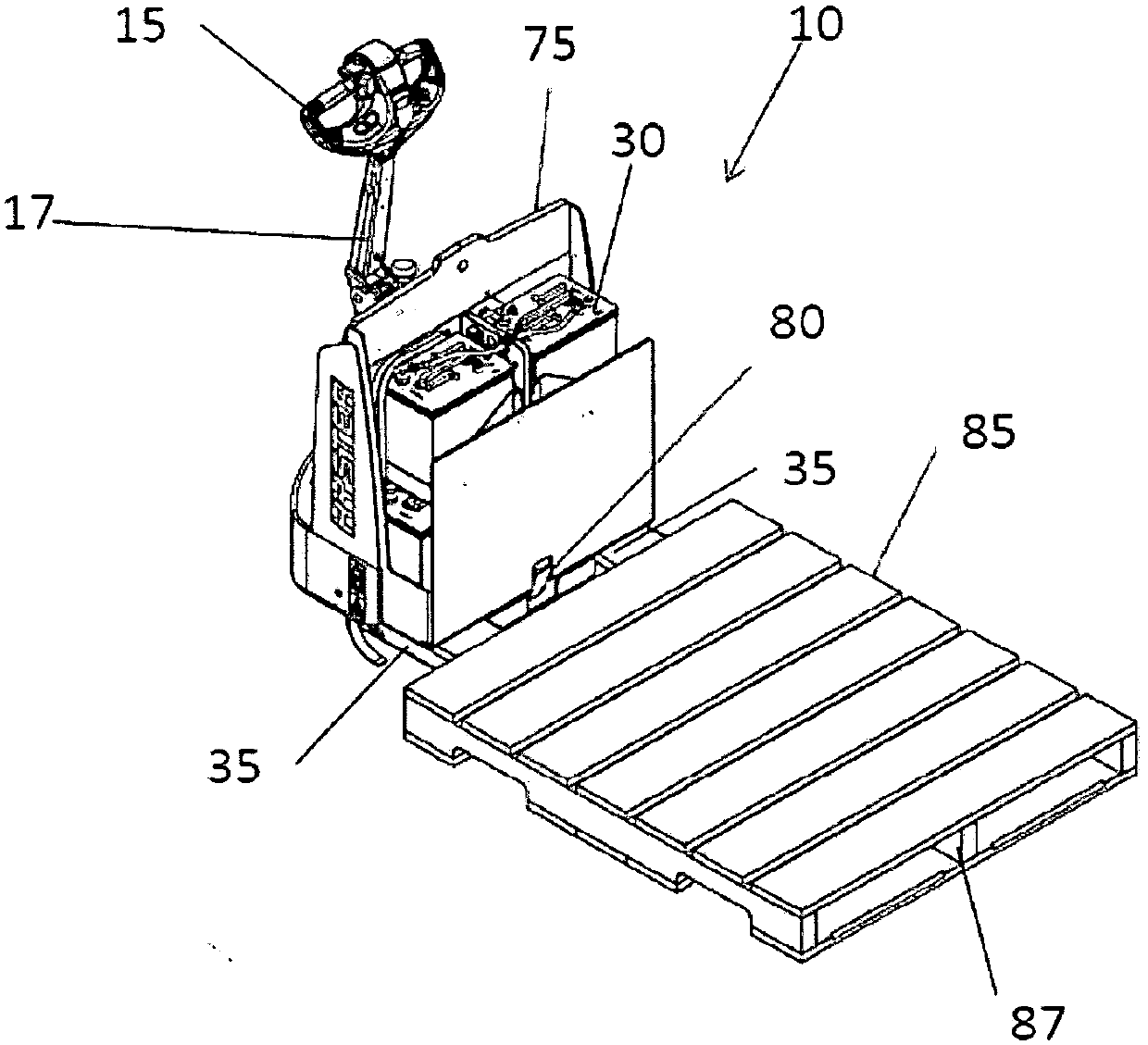

[0035] figure 2 Illustrated figure 1 Right rear isometric view of the exemplary pallet jack 10 of . An optional second lift actuator is included on the frame 75 of the pallet jack 10 , however the secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap