Oil sludge adsorption material stirring kettle

An adsorption material and a stirring tank technology, which is applied in the field of stirring tanks, can solve the problems of inconvenient adjustment, easy toppling of the stirring tank, and inability to adjust the device to a balanced state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

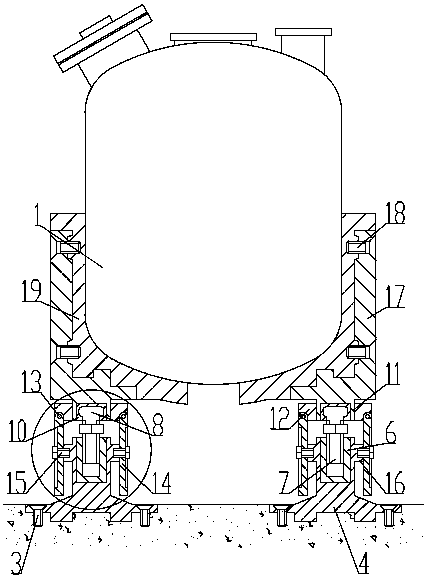

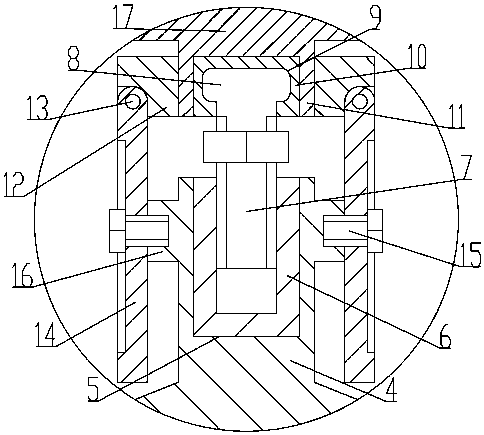

[0011] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0012] A stirred tank for oily sludge adsorption material, comprising a stirred tank 1, a supporting base 4, a fixed sleeve 6, an adjusting rod 07, a rotating sleeve 10, a reinforcing rod 14, a mounting plate 17, and a fixed plate 19, the supporting base 4 is fixed by The nail 3 is connected to the ground, the support base 4 has a fixed sleeve groove 5 inside, the fixed sleeve groove 5 is compatible with the fixed sleeve 6, the fixed sleeve 6 is connected to the fixed sleeve groove 5, and the inside of the fixed sleeve 6 is connected with the adjustment rod 07, the adjustment rod 07 is connected to the fixed sleeve 6, the fixed sleeve 6 and the adjustment rod 07 are engaged with each other, the upper part of the adjustment rod 07 has a rotating protrusion 8, and the fixed plate 19 is compatible with the stirring tank 1, The stirred tank 1 is connected to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com