Peripheral barrier-free clamp for palletizing robot

A palletizing robot and gripper technology, which is applied to the parts and packaging of strapping machines, can solve the problems of inconvenience, cost increase, and production efficiency reduction, and achieve the effects of convenient use, avoiding investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

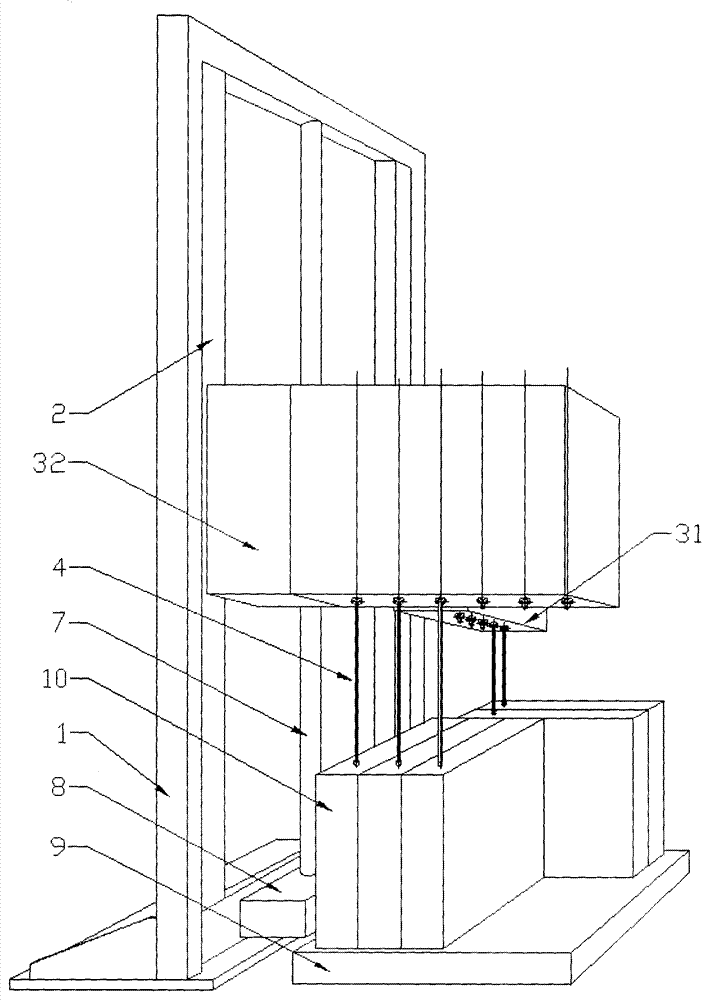

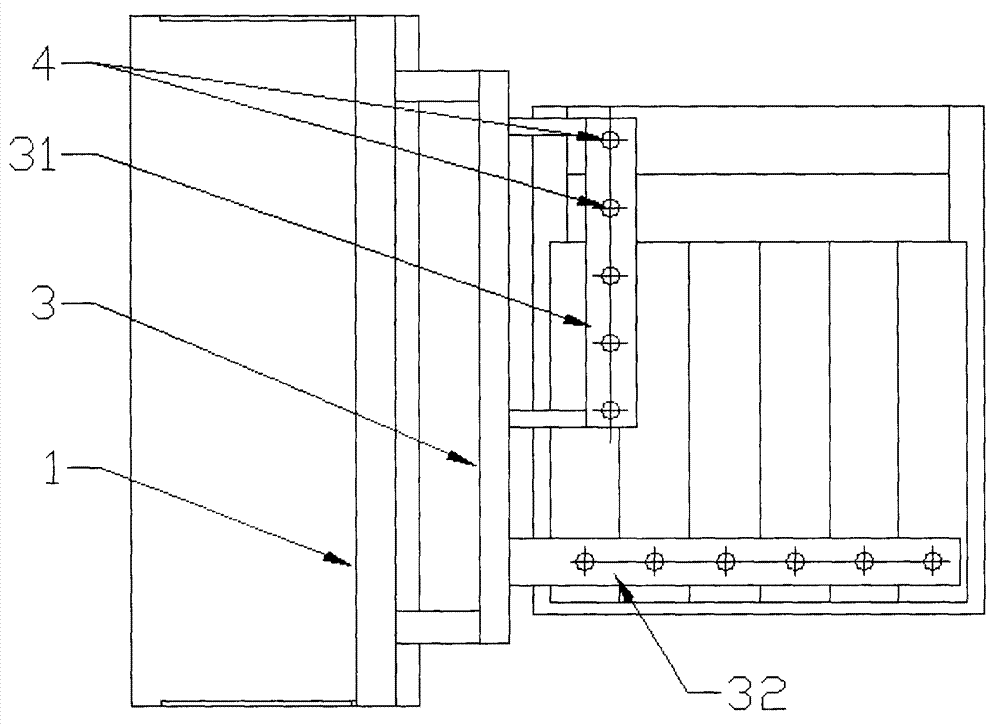

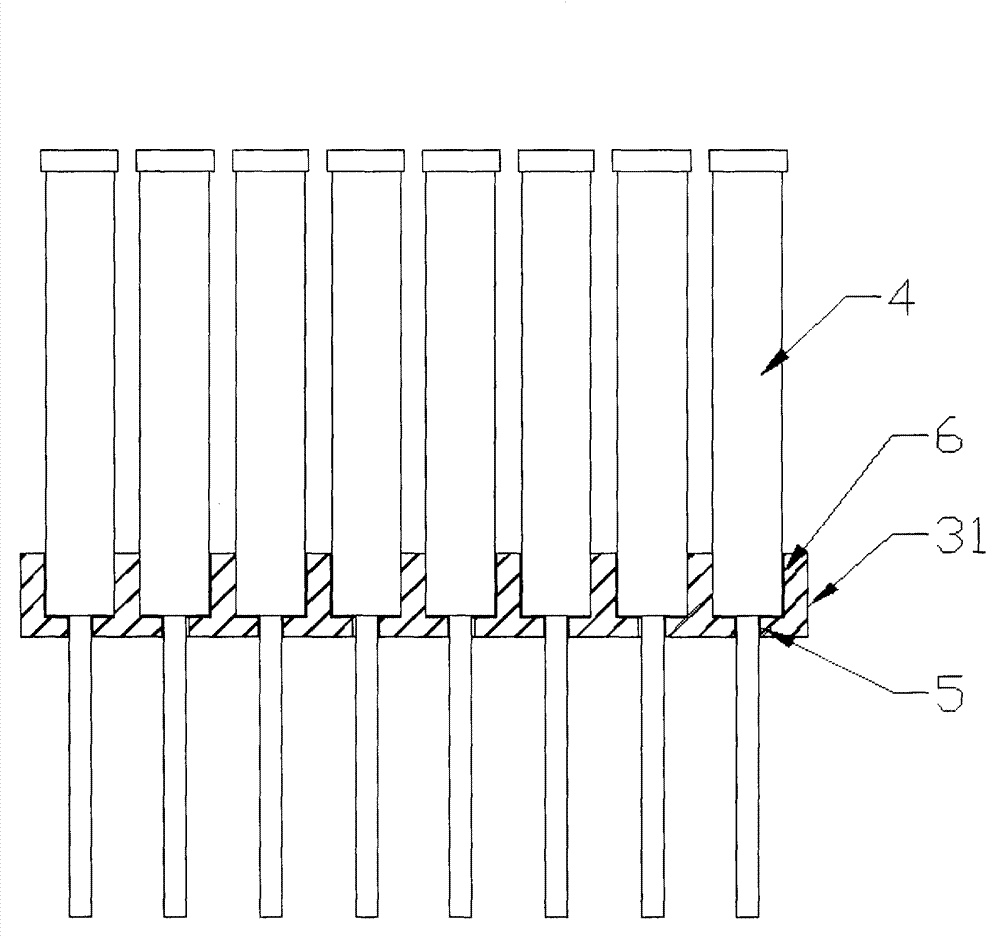

[0019] Such as Figure 1 to Figure 3 As shown, in this embodiment, the present invention includes a frame 1, on which a guide rail 2 is arranged, on which a cylinder assembly frame 3 is slidably fitted, and the cylinder assembly frame 3 Driven by the power device arranged on the frame 1 to move up and down on the guide rail 2, several vertically arranged cylinders 4 are arranged in the cylinder assembly frame 3, and the output of several cylinders 4 Shaft facing down. The area of the orthographic projection of the cylinder pallet 3 is equivalent to the area of the peripheral cargo board. Universal wheels are arranged on the bottom plate of the frame 1 , and the holder can be moved in the workshop through the universal wheels. The power device can have the following two structures.

[0020] 1. The power device is a screw rod 7 arranged on the frame 1, the screw rod 7 passes through the threaded hole arranged on the cylinder assembly frame 3, and is set on the frame 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com