A method for realizing automatic press-fitting of perforating charges

A perforating charge, fully automatic technology, applied in assembly machines, earth-moving drilling, wellbore/well components, etc., can solve problems such as constraints on production efficiency and product quality stability, large technical gaps, and backward automation of press-fitting equipment. problems, to improve the efficiency of press-fitting and product quality stability, reduce the probability of occurrence, and achieve the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

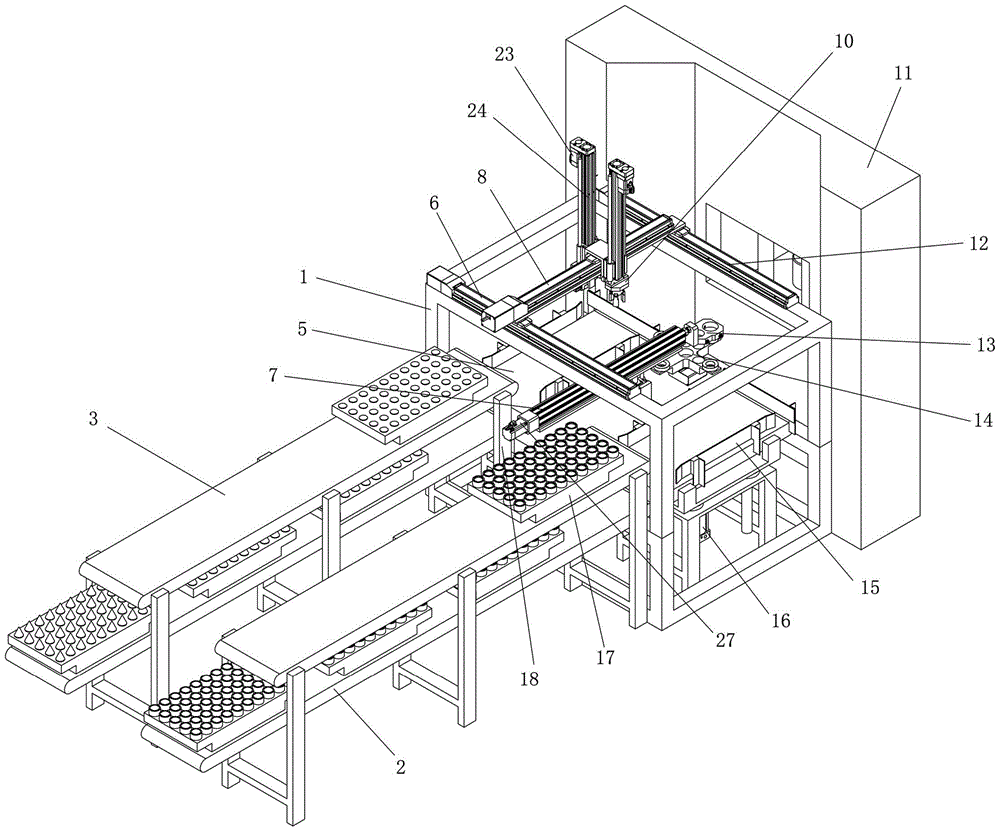

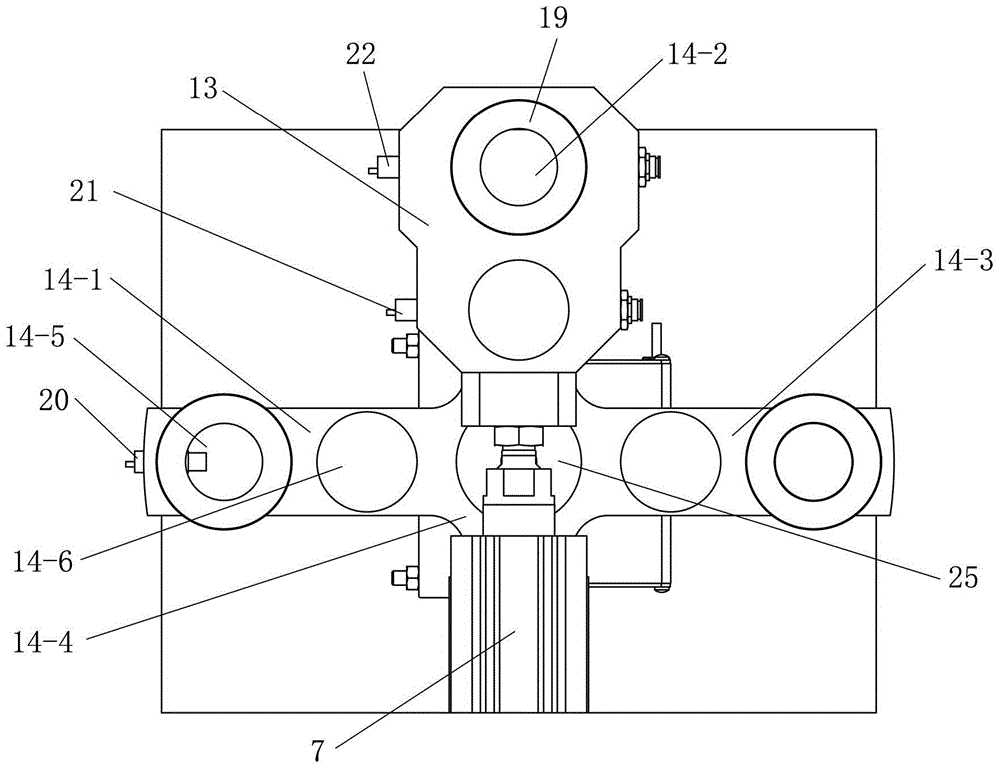

[0032] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout.

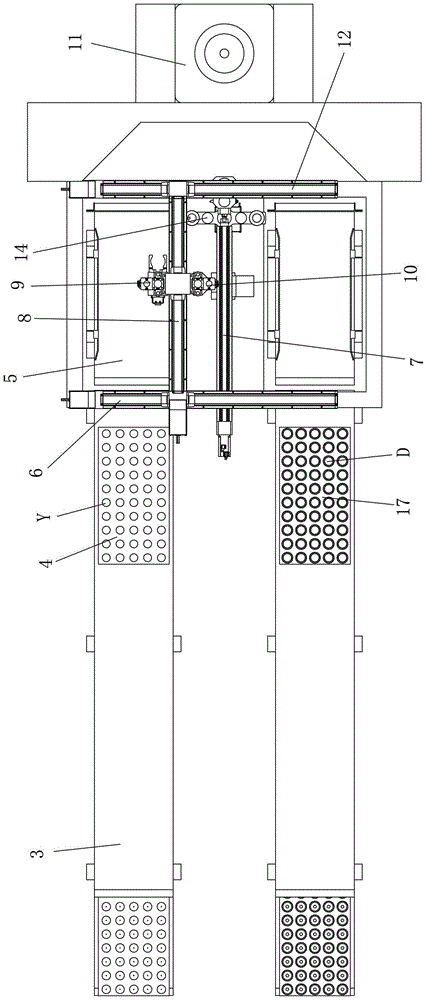

[0033] refer to Figure 1 to Figure 4 According to the present invention, the fully automatic press-fitting equipment mainly includes a frame 1, at least two sets of conveyor belts, a pick-up device and a control system.

[0034] The frame 1 can be made of various steel frames, etc., and is used to support the conveyor belt and the pick-up device.

[0035] The fully automated press-fitting equipment may specifically include two sets of conveyor belts to respectively convey the liner Y and the projectile body D used for press-fitting the perforating charge, wherein the projectile body D is a combination of explosives and shells. The structure of each group of conveyor belts is the same, and can include an upper conveyor belt 3, a lower conveyor belt 2 and a lifting conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com