Dumper

A technology of dump trucks and frames, applied to vehicles with chains/belts, etc., can solve the problems of slow loading speed and large damage to goods, and achieve the effects of simplifying the loading process, small bumps, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

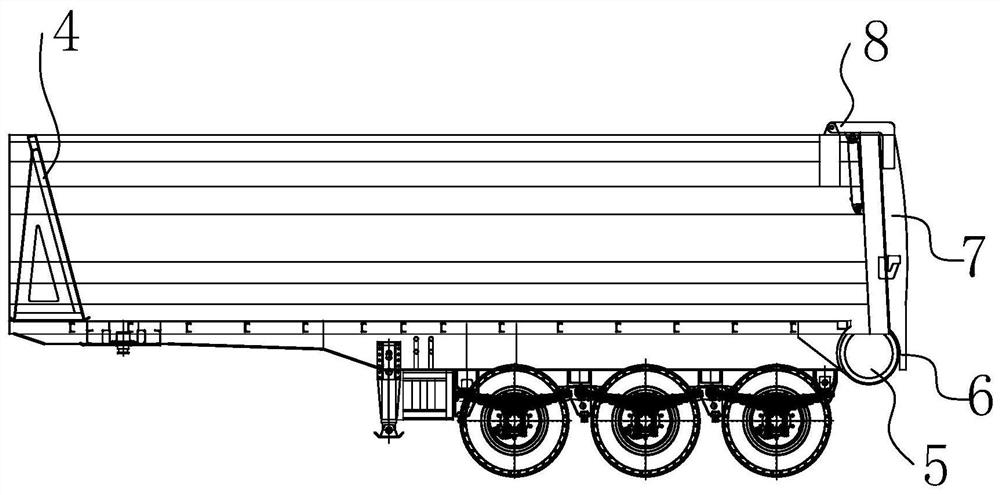

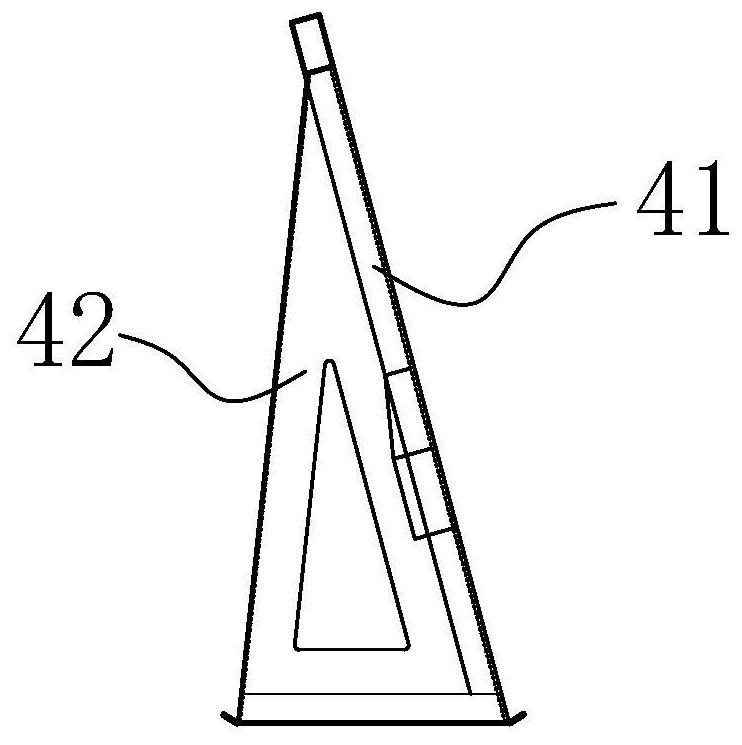

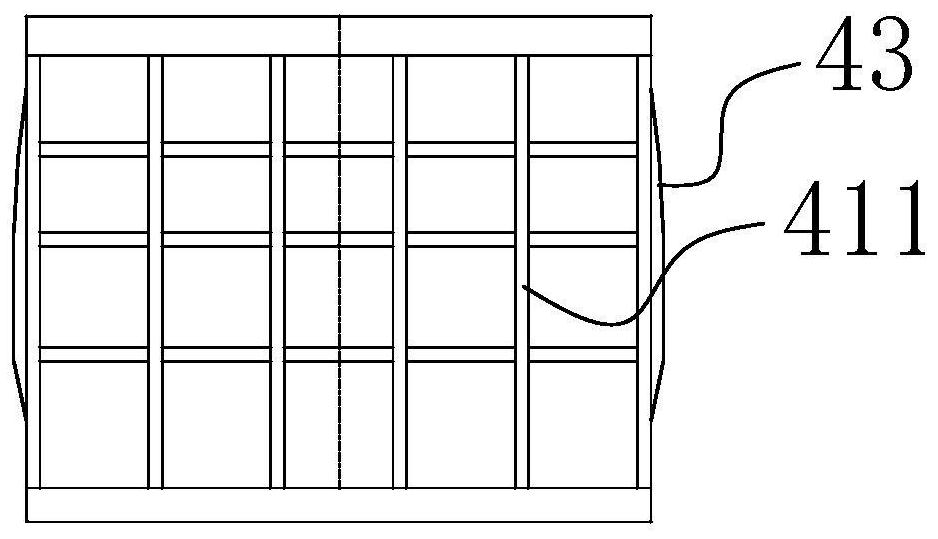

[0035] This embodiment provides a dump truck, which includes a vehicle frame on which a compartment is installed. In this embodiment, a baffle plate 4 is arranged laterally in the compartment. The baffle plate 4 is slidably connected in the compartment, and can slide forward and backward in the compartment. The upper surface of the bottom plate of the compartment is provided with a conveyor belt 6, and the front end of the conveyor belt 6 is connected to the rear portion of the baffle plate 4, so that the baffle plate 4 and the conveyor belt 6 become an integral body. The plate 4 and the conveyor belt 6 move synchronously. Wherein, the synchronous movement mode is as follows: when the conveyor belt 6 moves back and forth, the baffle plate 4 moves along with the conveyor belt 6 . In the rear portion of the vehicle frame, a drum 5 is also installed, and the conveyor belt 6 is connected with the drum 5; a first driving device is installed on the drum 5, and the first driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com