Automatic alignment device for tube plate welding robot

An automatic alignment and tube-to-sheet welding technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity, low degree of automation, and difficult to determine the adjustment amount, so as to reduce the labor intensity of workers and improve Efficiency, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention. In the following detailed description, certain exemplary embodiments of the invention are described by way of illustration only.

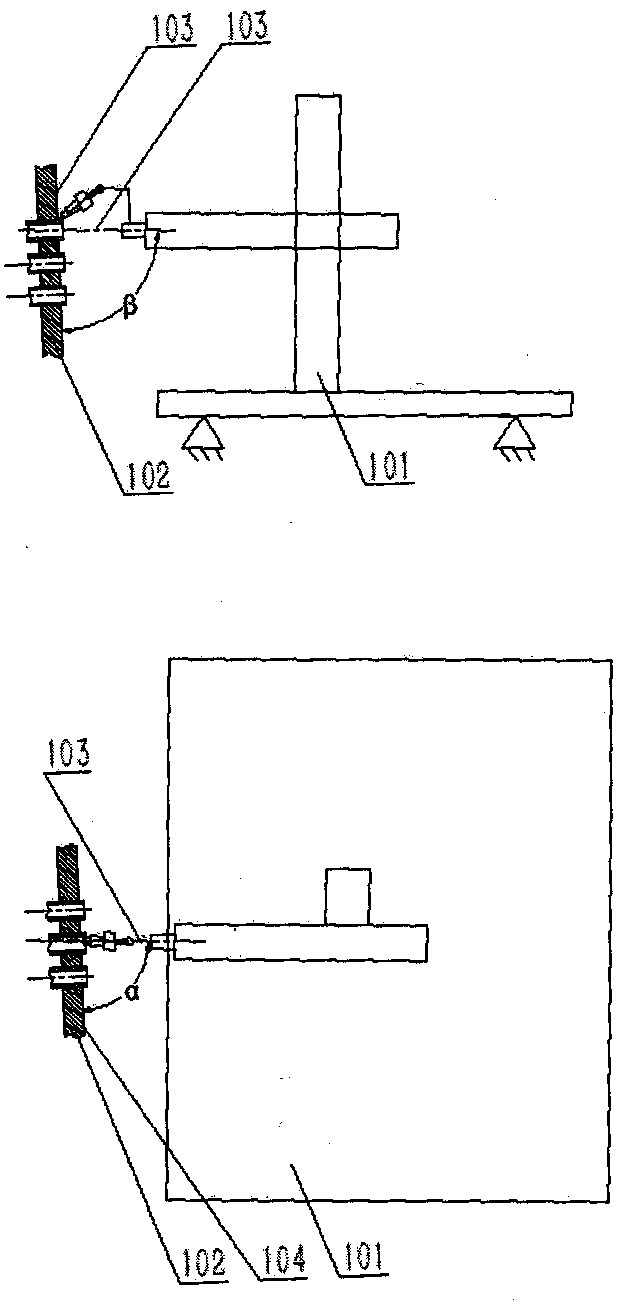

[0014] Such as figure 1 As shown, the tube-sheet welding robot 101 is placed on the ground. Due to the unevenness of the ground and the improper placement of the tube-sheet workpiece 102, the rotation axis 103 of the welding torch is not perpendicular to the plate surface 104, and the rotation axis 103 of the welding torch is not perpendicular to the plate surface. The angle between the horizontal direction of 104 is α, and the angle between the rotating shaft 103 of the welding torch and the vertical direction of the plate surface 104 is β. When these two angles exceed 0.3°, the welding quality will be greatly affected.

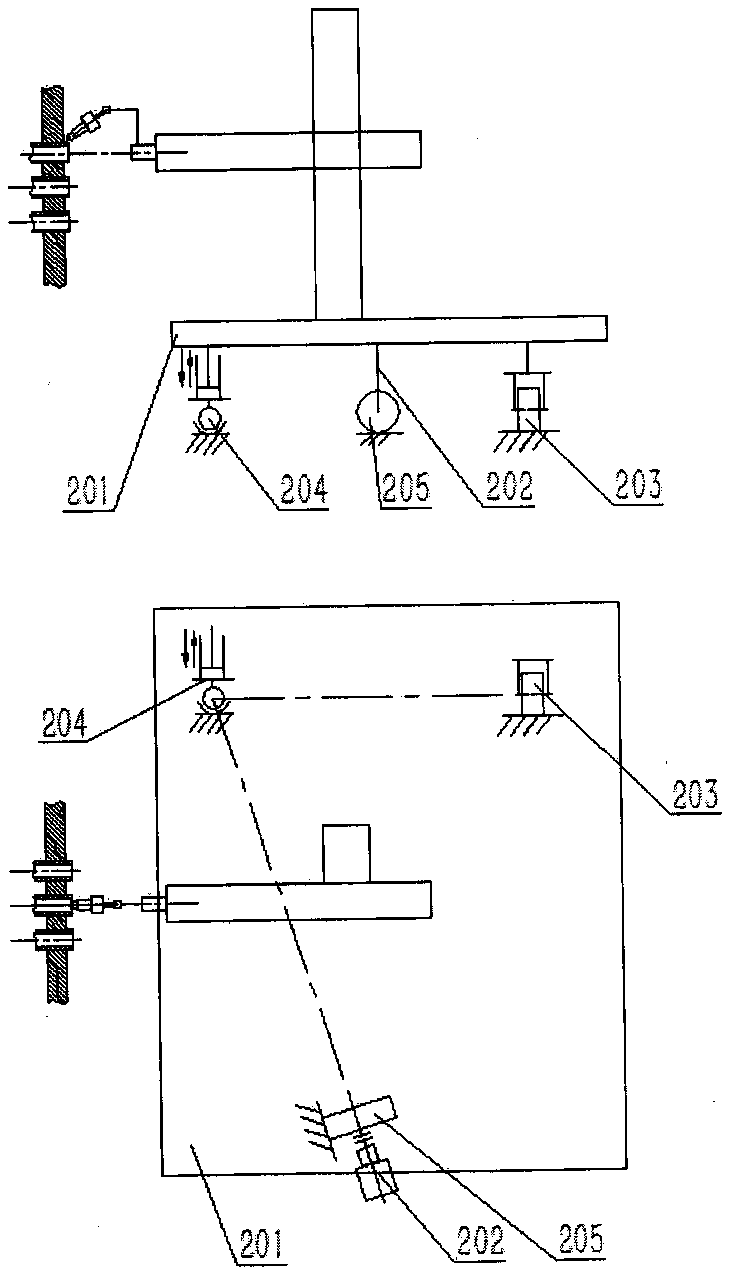

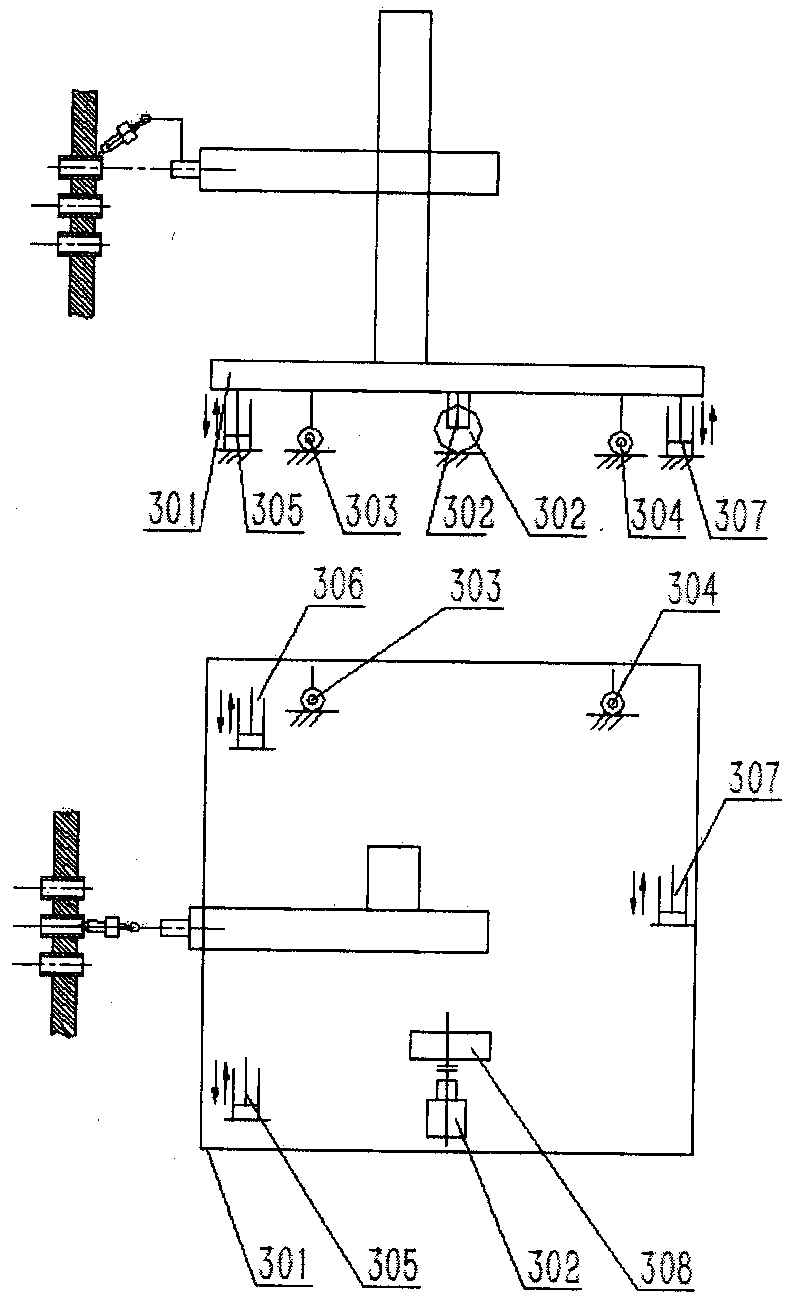

[0015] Such as figure 2 As shown, the automatic alignment device of the tube-sheet welding robot is composed of a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com