Screen protector repair method and screen protector pasting method

A protective film and film sticking technology, which is applied in the field of liquid crystal screen protective film repair method and film sticking, can solve the problems such as white spots on the protective film, and achieve the effects of eliminating white edges, increasing durability, and reducing broken edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

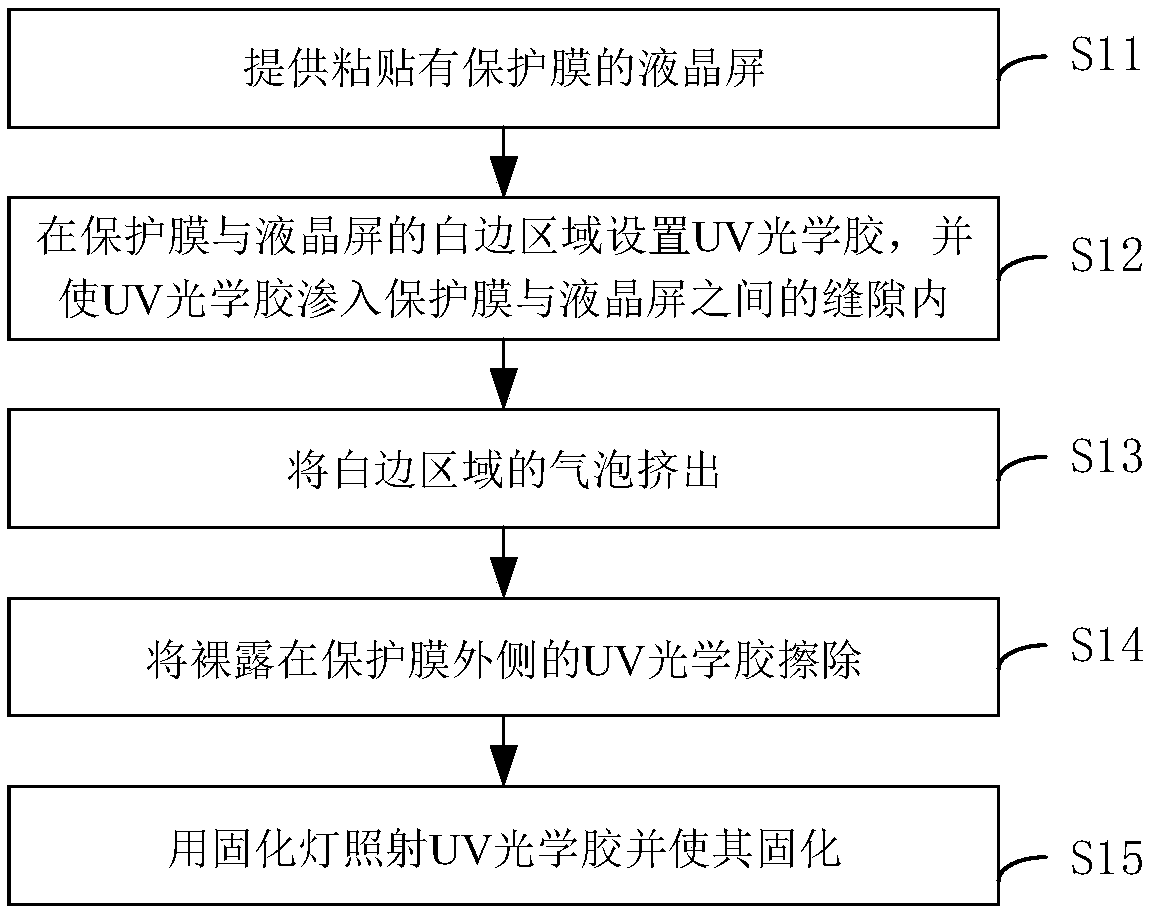

[0037] This embodiment provides a protective film repair method. Such as figure 1 As shown, the protective film repair method includes the following steps:

[0038] Step S11, providing a liquid crystal screen pasted with a protective film.

[0039] The protective film can use but is not limited to existing or future protective films such as tempered film and high-definition film. The liquid crystal screen can be, but not limited to, a mobile phone liquid crystal screen, a tablet computer liquid crystal screen and an e-book liquid crystal screen, and the mobile phone liquid crystal screen can be a flat liquid crystal screen, a curved liquid crystal screen or a full-screen liquid crystal screen. After the protective film is pasted on the surface of the liquid crystal screen according to the existing method, there will be white edges in the edge area of the protective film. The main reason for the white edge phenomenon is that there is a gap between the protective film and t...

Embodiment 2

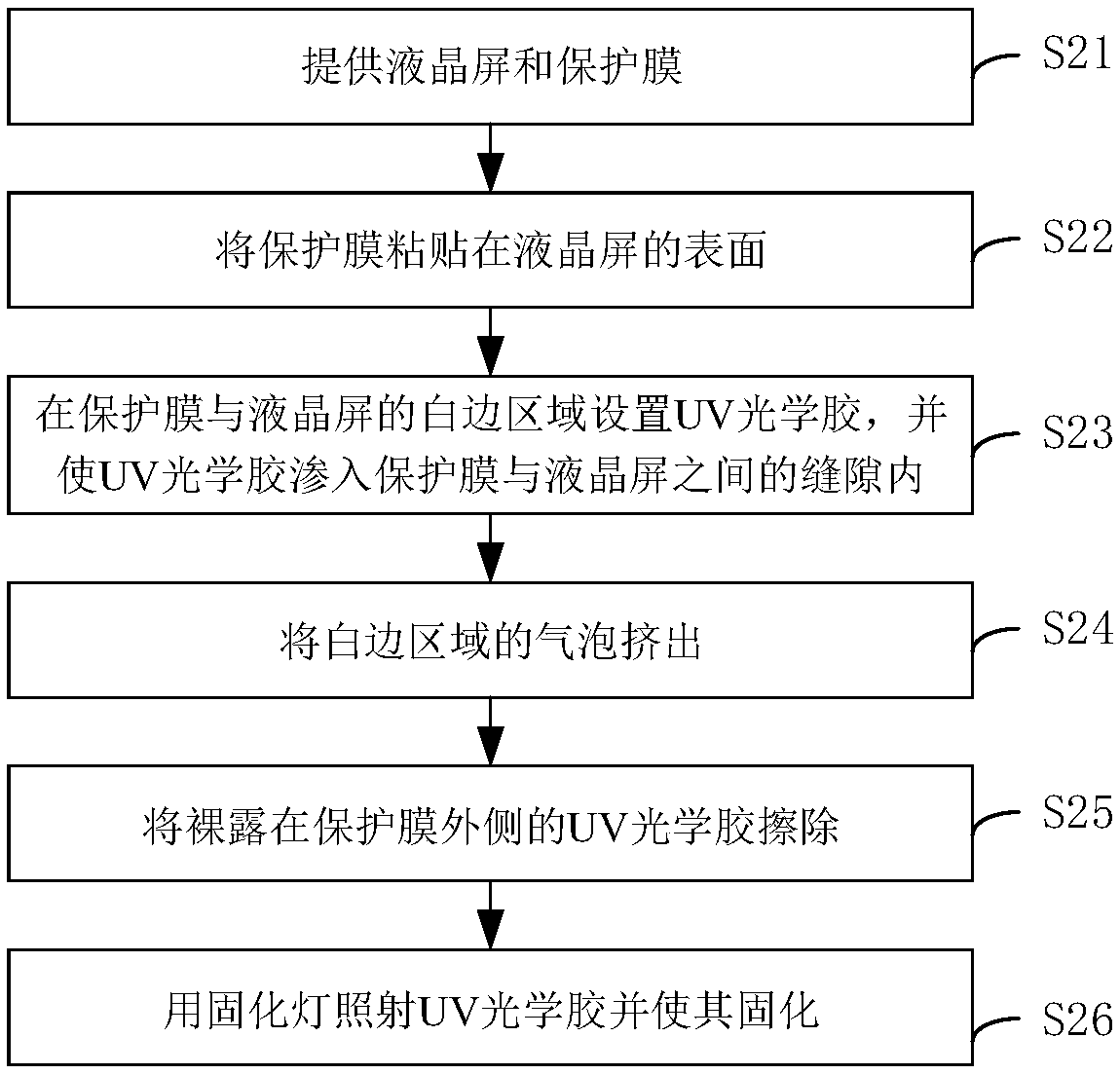

[0050] This embodiment provides a film sticking method. Such as figure 2 Shown, the method of this film sticking method comprises the following steps:

[0051] Step S21, providing a liquid crystal screen and a protective film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com