Rope guide with pressing wheel type rope pressing device and guide rod type guiding mechanism

The technology of a rope pressing device and a guiding mechanism is applied in the field of rope guides, which can solve the problems of breaking or pulling away, small lateral force, disorder of wire ropes, etc., and achieves convenient adjustment of center distance changes and resistance to oblique pulling. The effect of strengthening and enhancing the cable-pulling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

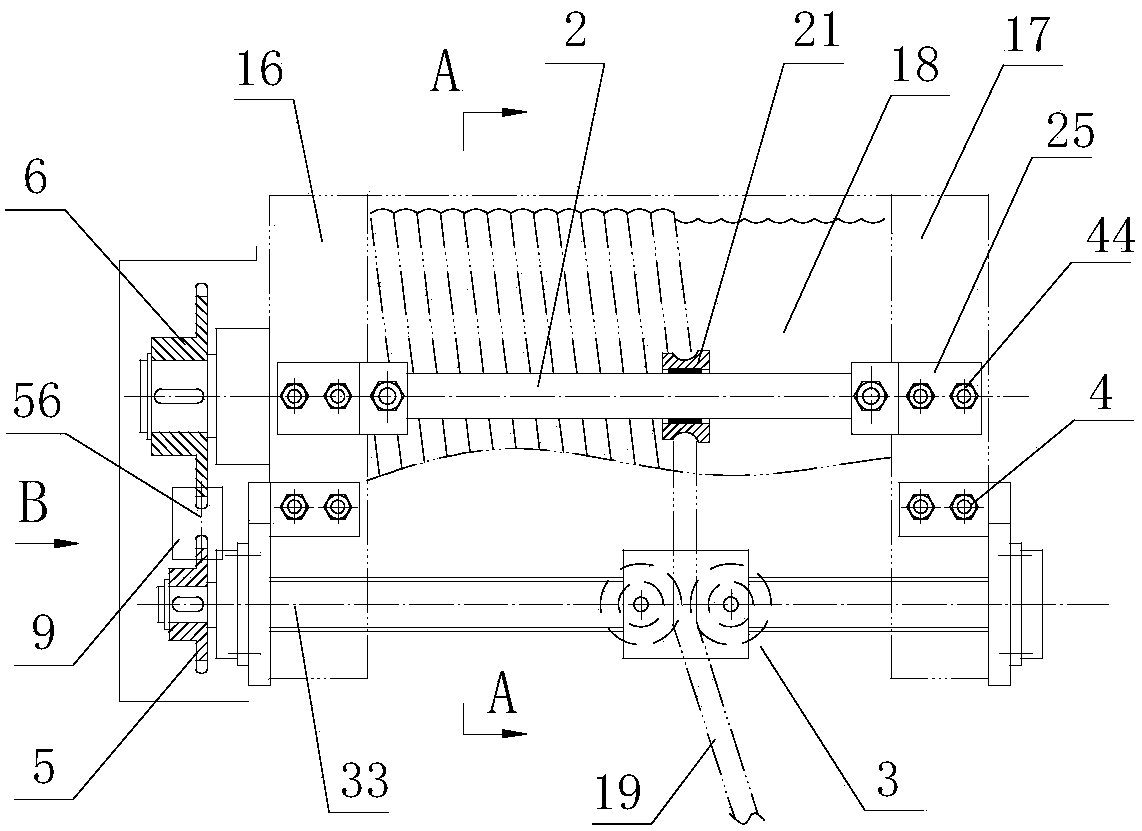

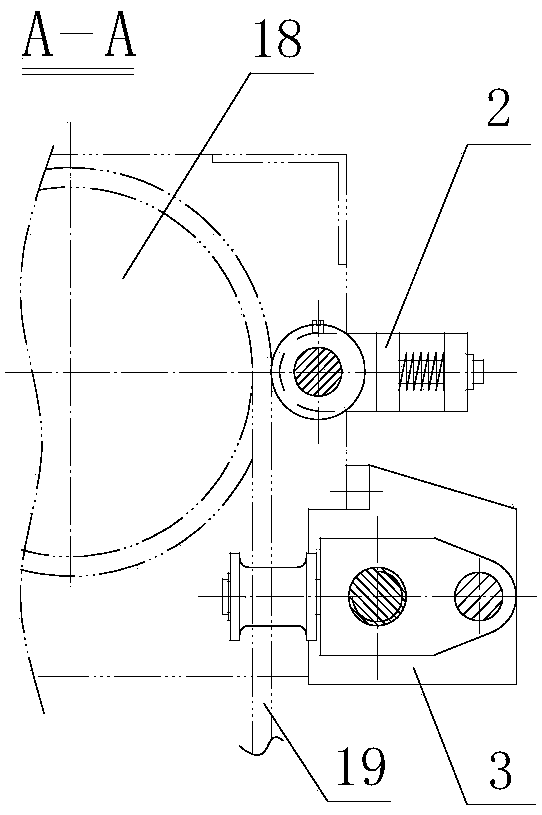

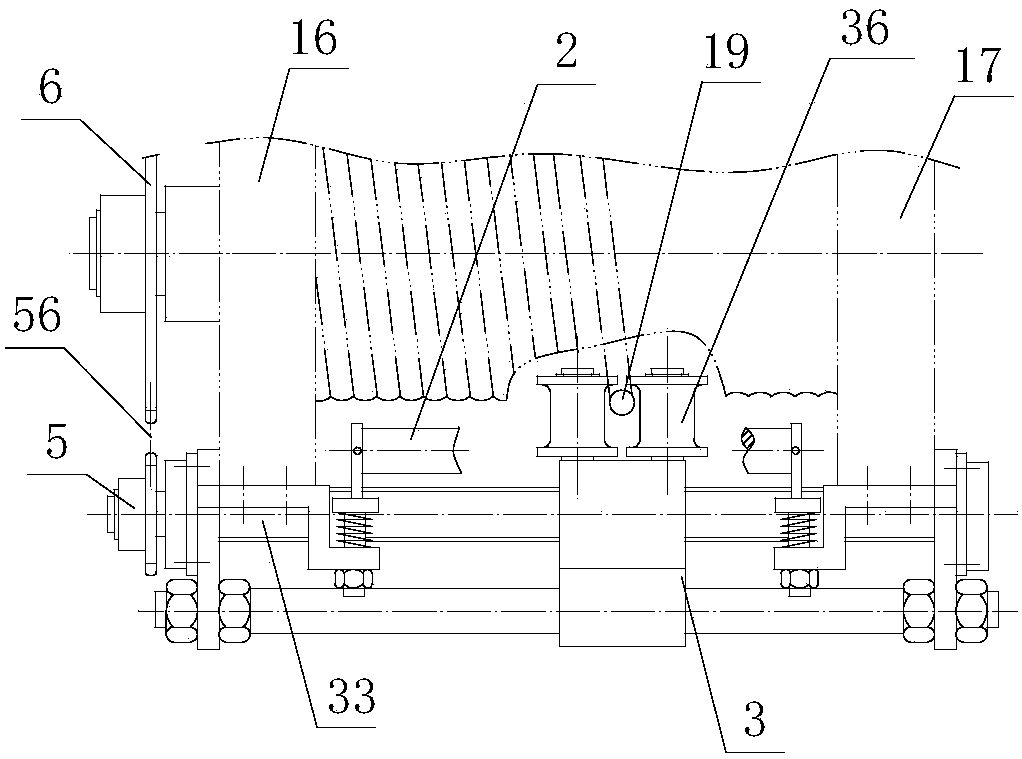

[0021] Such as figure 1 , figure 2 , image 3 As shown, a rope guide with a pressure wheel type rope pressing device and a guide rod type guiding mechanism includes a pressure wheel type rope pressing device 2 and a guide rod type thread guide mechanism 3; in the pressure wheel type rope pressing device The fixed seat of the reel is connected to the front of the reel by bolts, and the pressure roller is pressed on the steel wire rope of the last circle of the reel; the guide rod type thread guide mechanism is connected to the front of the reel by bolts 4 and is located at the pressure roller directly below the rope pressing device; one end of the threaded shaft 33 on the guide rod type threaded guide mechanism is connected to the small sprocket 5; the small sprocket is connected to the large sprocket 6 through a chain 56; the large sprocket is connected to One end of the reel shaft of the electric hoist; the chain 56 is connected with a tensioning device 9; the tensioning d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com