A spray-molded high-density polyurethane foam and its preparation method

A polyurethane foam and high-density technology, which is applied in the fields of box and pipeline insulation, interlayer filling, and buffer layer. It can solve the problems of foam heat dissipation, fast accumulation of reaction heat and slow transfer, foam prone to core burning, etc., to achieve excellent heat preservation Performance and mechanical strength, density and total thickness can be adjusted, and the effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

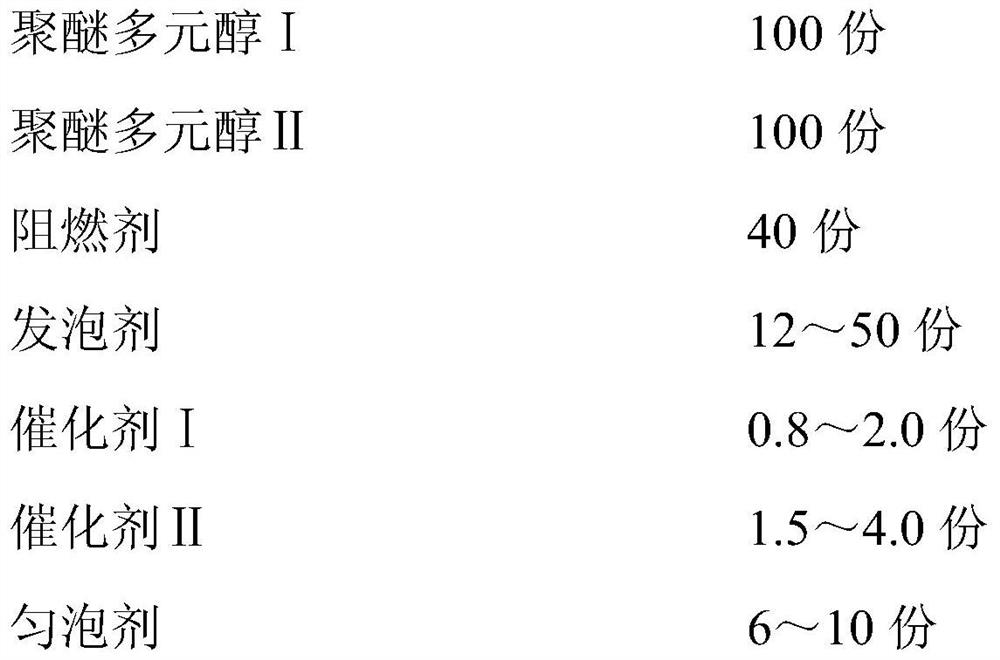

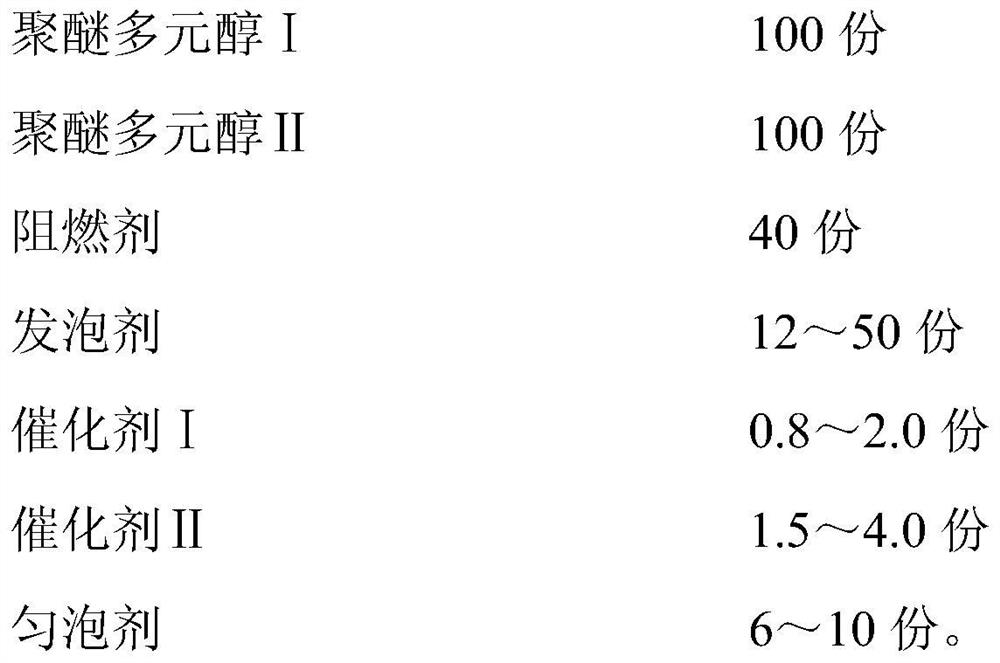

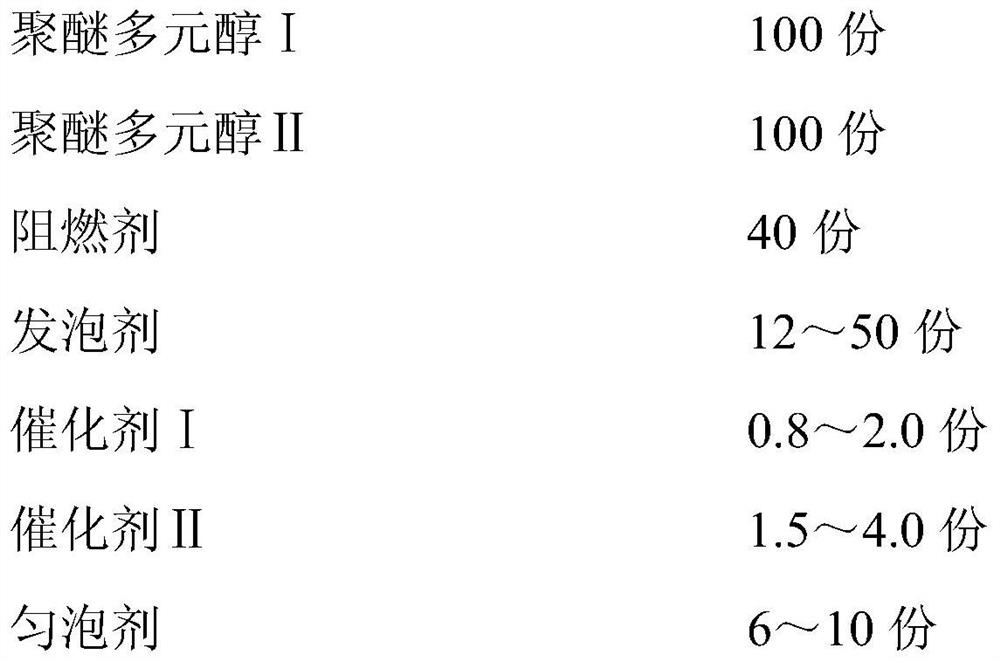

[0038] The preparation method of above-mentioned spray molding high-density polyurethane foam comprises the following steps:

[0039] (1) To prepare component A, take 100 parts of polyether polyol I, 100 parts of polyether polyol II, 40 parts of flame retardant, 15-50 parts of blowing agent, 0.8-2.0 parts of catalyst I, 1.5-4.0 parts of catalyst Ⅱ. 6~10 parts of foam stabilizer, placed in a mechanical mixing tank and stirred for 20~30 minutes, poured into the material tank of component A for spraying, and the pump of component A is submerged in the material.

[0040] (2) Component B material distribution Put plastic gauze on the mouth of component B material barrel for spraying, take 280-395 parts of polymethylene polyphenyl isocyanate, filter through plastic gauze, and remove the crystal particles that may exist in it , Pour it into the material barrel, and the component B lifting pump is submerged in the material.

[0041] (3) Temperature and humidity control of the spray b...

Embodiment 1

[0047] A spray-molded high-density polyurethane foam and a preparation method thereof, comprising the steps of:

[0048] (1) Take 10kg polyether polyol Ⅰ, 10kg polyether polyol Ⅱ, 4kg flame retardant, 4kg foaming agent, 0.15kg catalyst Ⅰ, 0.35kg part catalyst Ⅱ, 0.8kg foam stabilizer, and place them in a mechanical mixing tank Stir inside for 20-30 minutes, then pour into the component A bucket for spraying, and the component A pump is submerged in the material.

[0049] (2) Lay plastic gauze on the mouth of component B material barrel for spraying, take 30kg polymethylene polyphenyl isocyanate, filter it through plastic gauze, pour it into the material barrel, and put the material pump of component B into the material .

[0050] (3) The temperature of the spray booth is 26°C, and the relative humidity is ≤57%.

[0051] (4) Set the feed volume ratio A:B=1.0:1.0, the feed pump pressure is 0.3MPa, the motor frequency is 36Hz, and the feed temperature is 45°C.

[0052] (5) Pro...

Embodiment 2

[0056] A spray-molded high-density polyurethane foam and a preparation method thereof, comprising the steps of:

[0057] (1) Take 10kg polyether polyol Ⅰ, 10kg polyether polyol Ⅱ, 4kg flame retardant, 3kg foaming agent, 0.15kg catalyst Ⅰ, 0.35kg part catalyst Ⅱ, 0.8kg foam stabilizer, and place it in a mechanical mixing tank Stir inside for 20-30 minutes, then pour into the component A bucket for spraying, and the component A pump is submerged in the material.

[0058] (2) Lay plastic gauze on the mouth of component B material barrel for spraying, take 30kg polymethylene polyphenyl isocyanate, filter it through plastic gauze, pour it into the material barrel, and put the material pump of component B into the material .

[0059] (3) The temperature of the spray booth is 25.3°C, and the relative humidity is ≤45%.

[0060] (4) Set the feed volume ratio A:B=1.0:1.0, the feed pump pressure is 0.3MPa, the motor frequency is 40Hz, and the feed temperature is 45°C.

[0061] (5) Pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com