A method for preparing reaction-sintered silicon carbide ceramic material with high density and low content of free silicon

A technology for sintering silicon carbide and ceramic materials, applied in ceramic molding machines, manufacturing tools, supply devices, etc., can solve the problems of large shrinkage of ceramic green bodies, low product density, and a large amount of organic binders, etc., and achieve the reduction of free silicon content , The effect of high ambient temperature and uniform product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

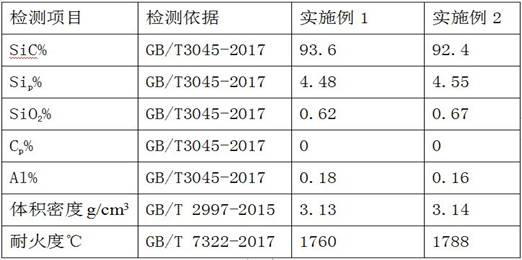

Examples

Embodiment 1

[0039] Embodiment 1 A kind of preparation method of high density and low free silicon content reaction sintered silicon carbide ceramic material

[0040] The preparation method of the reactive sintered silicon carbide ceramic material with high density and low free silicon content comprises the following steps:

[0041] 1. Mixing

[0042] Pour carbon black into a stirring tank with enough water for stirring, then add dispersant, binder, and decoagulant in sequence, stir for 30 minutes, and then add silicon carbide micropowder into it, mix evenly, and stir for 24 hours to obtain raw materials pulp;

[0043] The raw material slurry, in parts by weight, consists of:

[0044] Carbon black 9%, silicon carbide powder 70%, dispersant 1%, binder 0.5%, decoagulant 0.5%, purified water 19%;

[0045] The carbon black has a particle size of 36nm;

[0046] The silicon carbide micropowder has a particle size of 3-90um, wherein the particle size is 3um and accounts for 20% of the total w...

Embodiment 2

[0072] Embodiment 2 A kind of preparation method of high density and low free silicon content reaction sintered silicon carbide ceramic material

[0073] The preparation method of the reactive sintered silicon carbide ceramic material with high density and low free silicon content comprises the following steps:

[0074] 1. Mixing

[0075] Pour carbon black into a stirring tank with enough water for stirring, then add dispersant, binder, and decoagulant in sequence, stir for 30 minutes, and then add silicon carbide micropowder into it, mix evenly, and stir for 24 hours to obtain raw materials pulp;

[0076] The raw material slurry, in parts by weight, consists of:

[0077] Carbon black 8%, silicon carbide powder 65%, dispersant 2%, binder 0.5%, decoagulant 0.5%, purified water 24%;

[0078] The carbon black has a particle size of 40 nm;

[0079] The silicon carbide micropowder has a particle size of 3-90um, wherein the particle size is 5um and accounts for 20% of the total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com