Control method for secondary positioning in river model test

A technology of river engineering model and control method, applied in the direction of hydraulic engineering model, etc., can solve the problems of time-consuming, cumbersome, difficult to ensure accuracy, and has been displaced, and achieves the effect of fast positioning and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

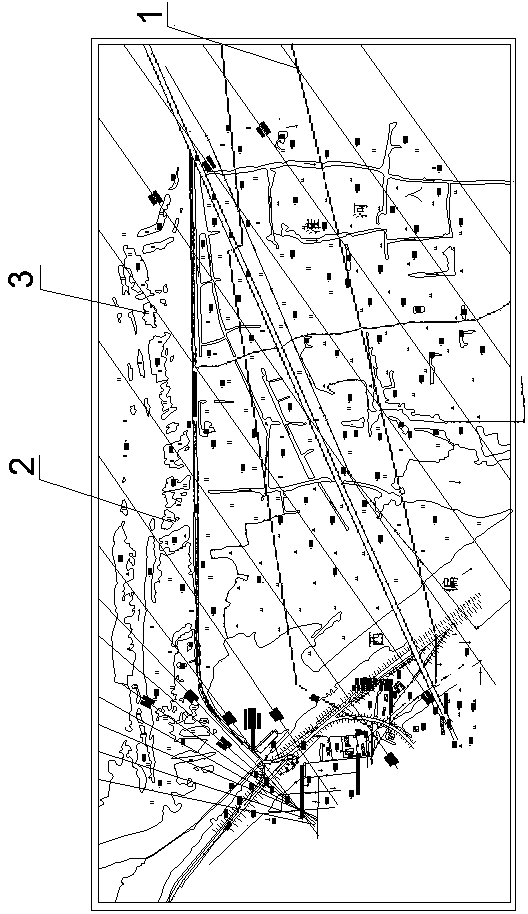

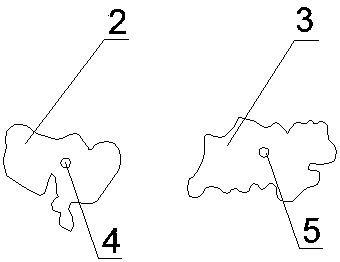

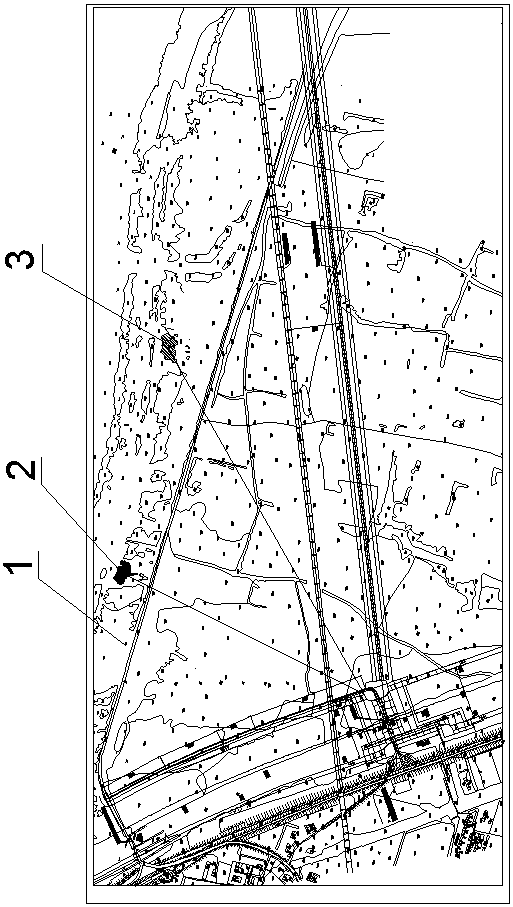

[0018] Attached below Figure 1-3 , the measurement and control principle and measurement and control process of the present invention are described in detail

[0019] A secondary positioning control method in a river engineering model test, characterized in that: using points in the primary river engineering model with obvious characteristics and whose positions do not change during the secondary production are used as positioning control points for the secondary model production, the primary river engineering model is reassessed modify the production;

[0020] Specifically include the following steps:

[0021] 1) Take the two positions in the primary river engineering model 1 with obvious features and the shape and position of the secondary production as the reference positions, and determine a reference point on each reference position;

[0022] In this embodiment, the small islands 2 and 3 are taken as reference positions on a river engineering model, and a reference poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com