Wheel tread abrasion detection method based on laser displacement sensor

A technology of laser displacement and wheel tread, applied in the direction of optical testing flaws/defects, instruments, measuring devices, etc., can solve the problems of complex measurement principle, poor system stability, low measurement accuracy, etc., to achieve simple measurement principle, system stability, measurement high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

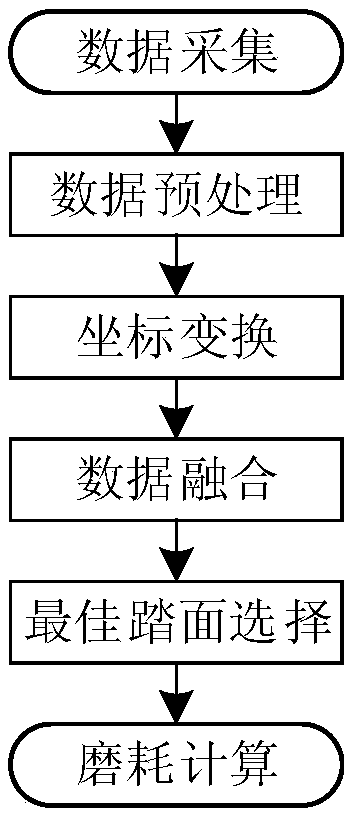

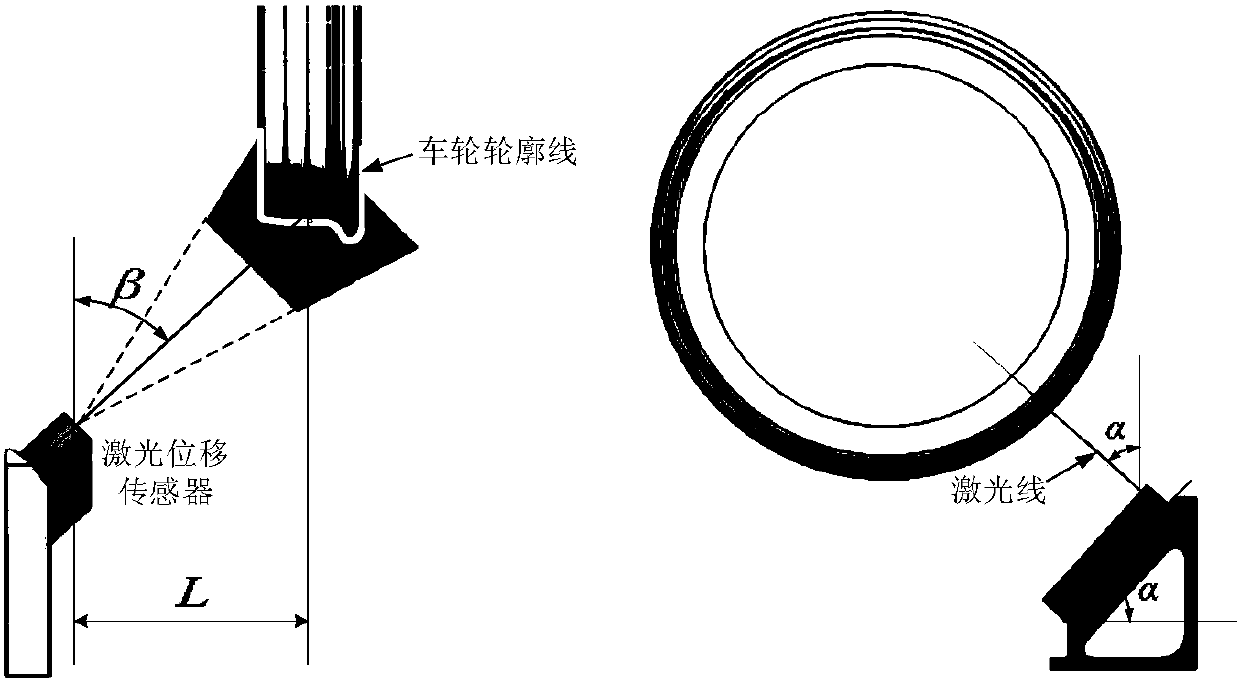

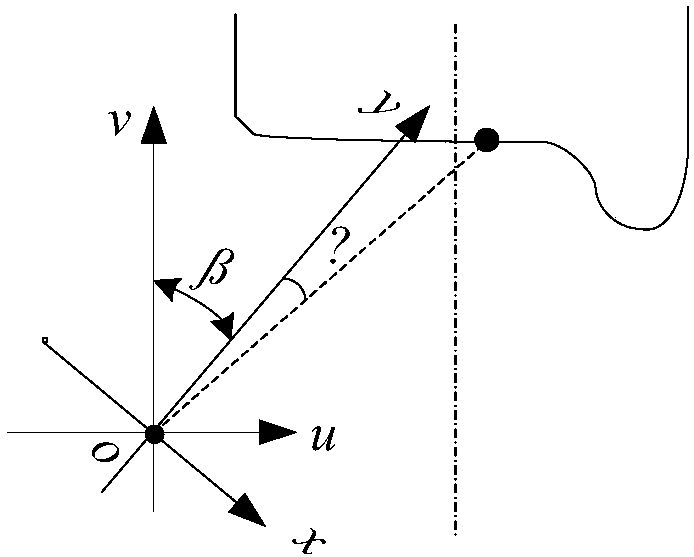

Method used

Image

Examples

Embodiment 1

[0062] In order to verify the effectiveness and accuracy of the wheel tread wear detection method proposed in this study, the project team conducted field experiments in Chisha Depot of Guangzhou Metro, including standard wheel set experiments and passing experiments. The tread wear value is the difference between the standard rim height and the actual wheel rim height, so the detection accuracy of the tread wear is equal to the detection accuracy of the rim height. For the convenience of expression, the experimental results are analyzed from the angle of the rim height.

[0063] In the standard wheel set experiment, the rim height of the selected standard wheel set is 28 mm. The standard wheel set is placed on the track, and the wheel set is manually pushed through the detection system at a slow speed. A total of 6 system measurements are made along the same direction. The results are as follows: Table 1 shows. It can be seen that the measurement error of the system is ±0.2mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com