AWB calibration method and device, computer readable storage medium and terminal

A calibration method and technology to be calibrated, applied in the field of image processing, can solve the problems of large white point gap, large calibration gain, inaccurate color temperature estimation, etc., to achieve accurate calibration, achieve accuracy, and reduce the effect of calibration gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

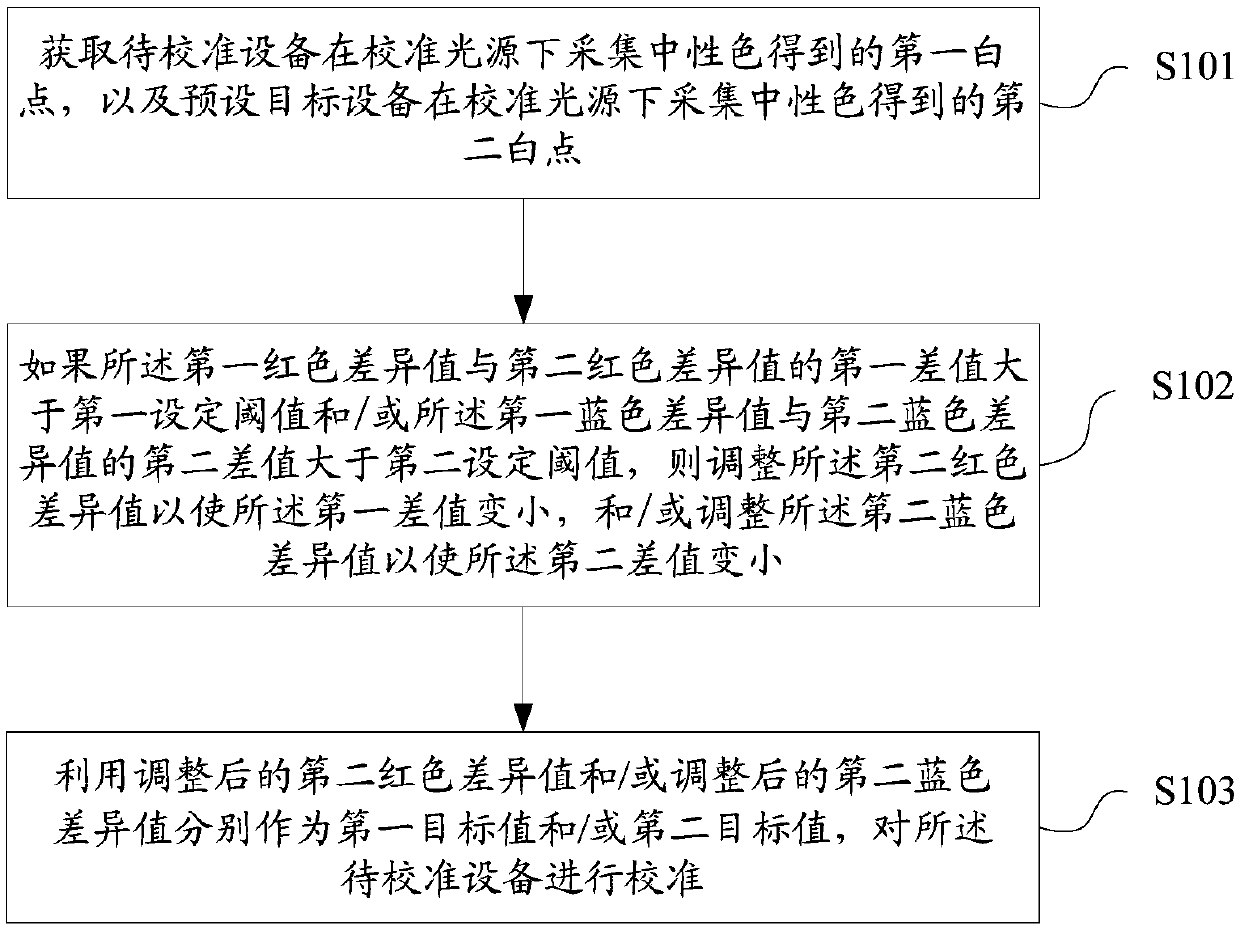

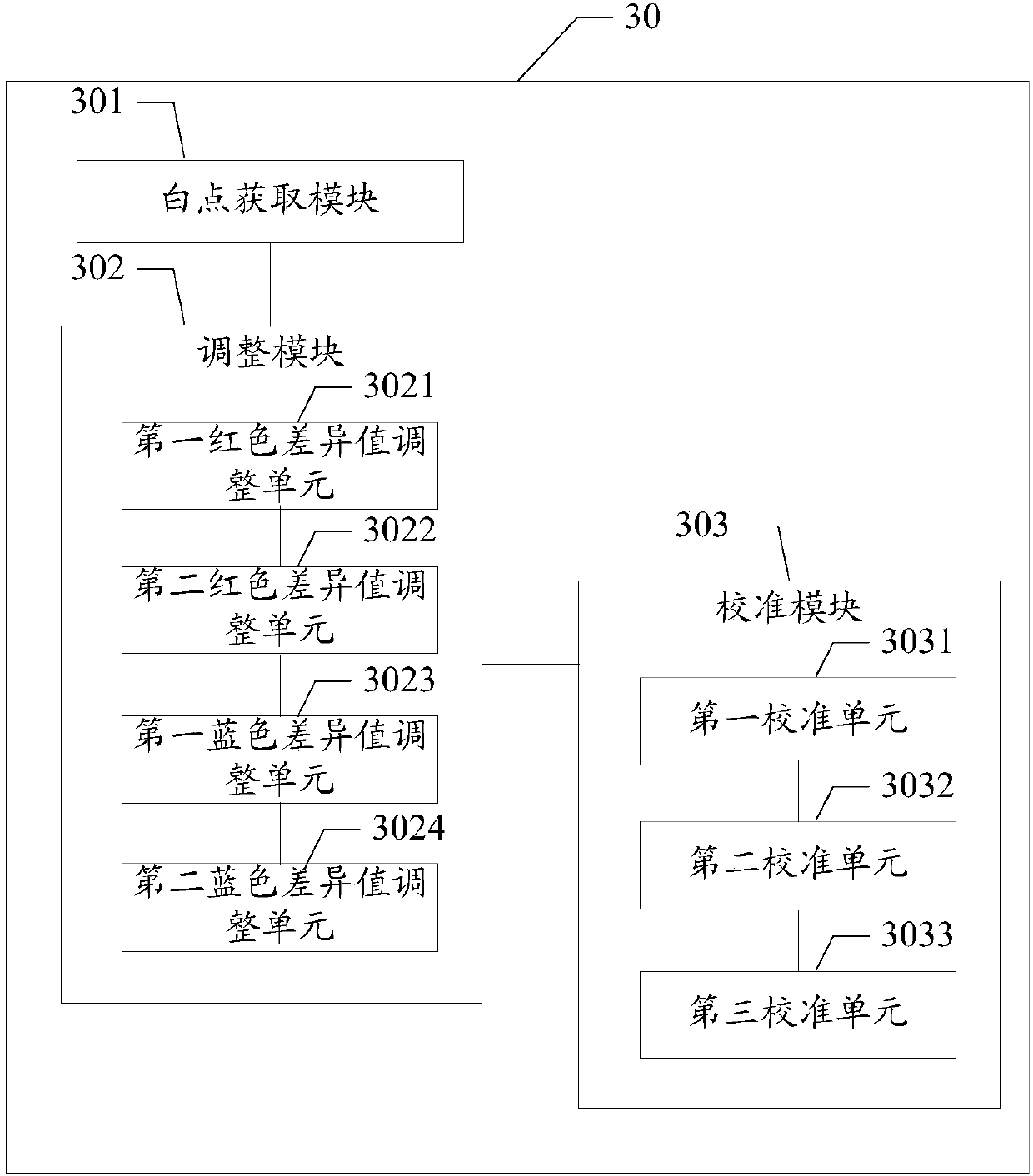

Method used

Image

Examples

Embodiment Construction

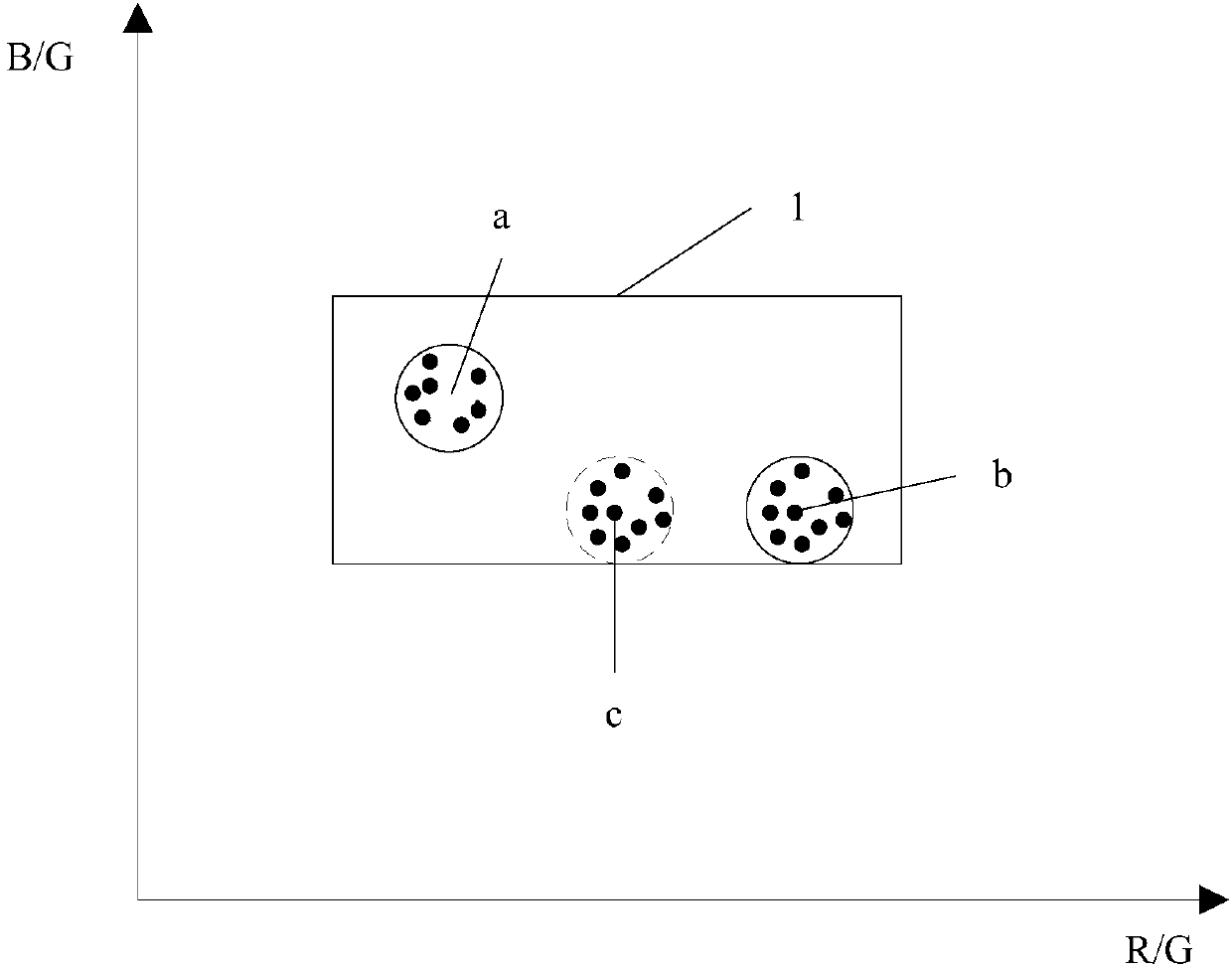

[0029] As mentioned in the background technology, for equipment within a small error range, such as equipment with an error of less than 10%, a more accurate calibration can be achieved by using the AWB calibration method of the prior art; and for equipment with a larger error, such as an error greater than 15% %, or even 20% of the equipment, using the AWB calibration method of the prior art may cause the calibration gain to be too large or too small, so that the gap between the calibrated white point and the white point of the target device is too large, and the calibration effect is poor, resulting in equipment The subsequent color temperature estimation is inaccurate, which reduces the image quality.

[0030] The inventors of the present application found that the existing AWB calibration method loses the effect of adjusting different devices to make the AWB performance consistent, resulting in the AWB performance of different devices being completely different from the tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com