A novel n-i-p-n half-mesa vertical silicon carbide avalanche diode and its preparation method

An n-i-p-n, silicon carbide avalanche technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of poor p-type ohmic contact quality, large etching depth, low work efficiency, etc., to reduce extraction The number of wires, improving the cost performance of the device, and reducing the effect of etching damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

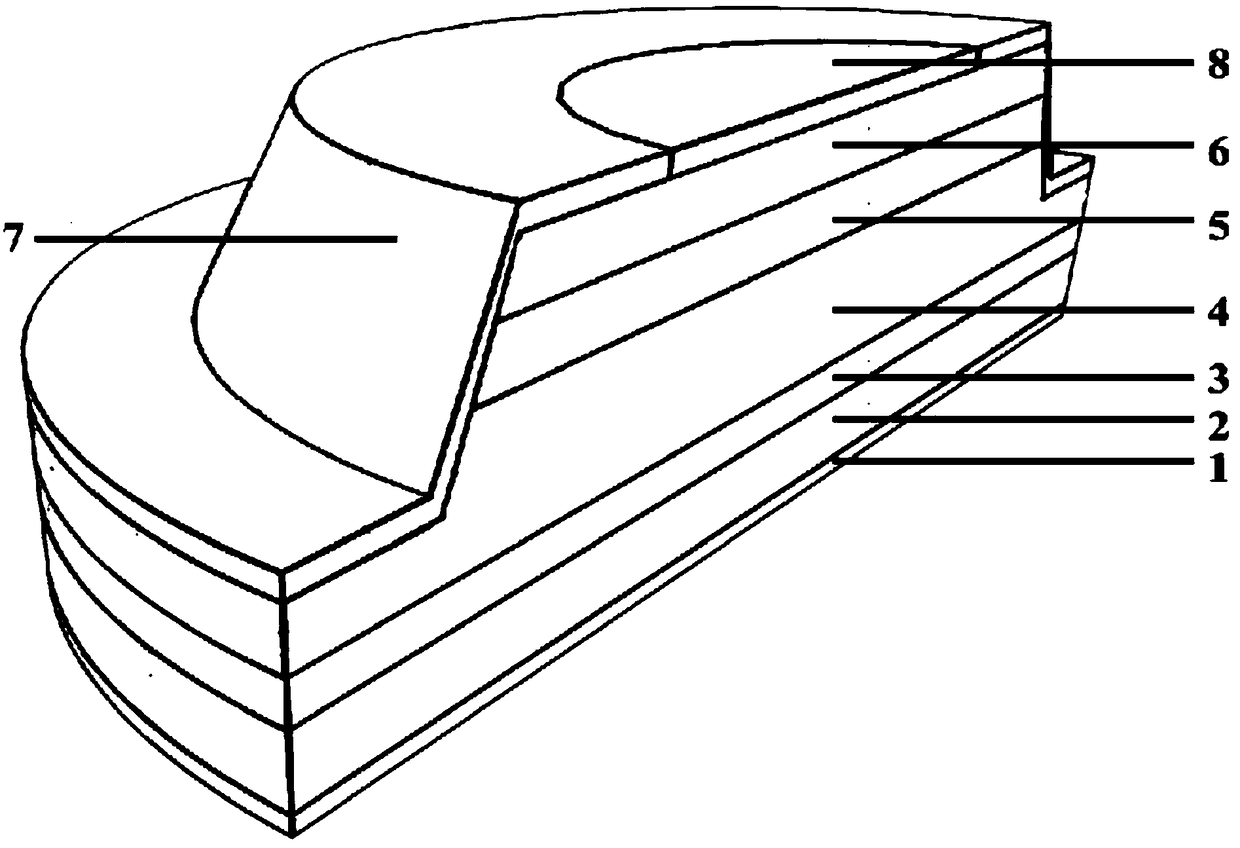

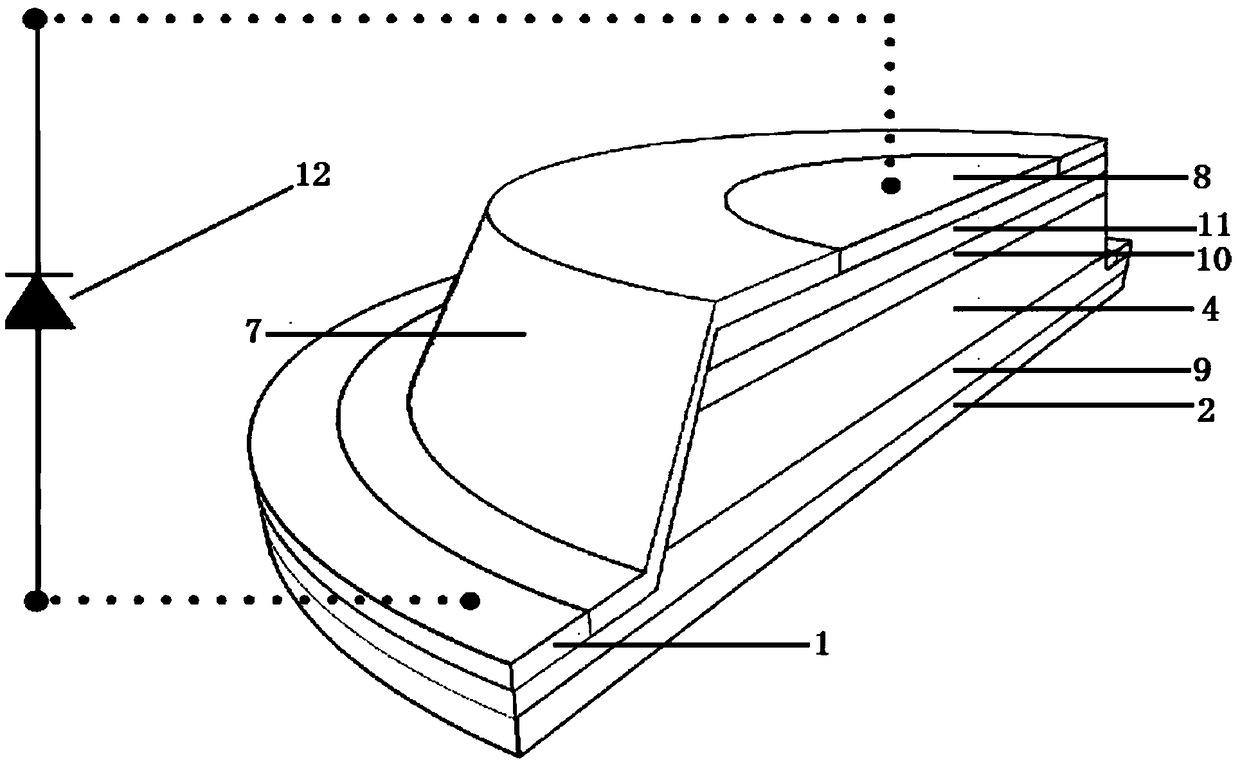

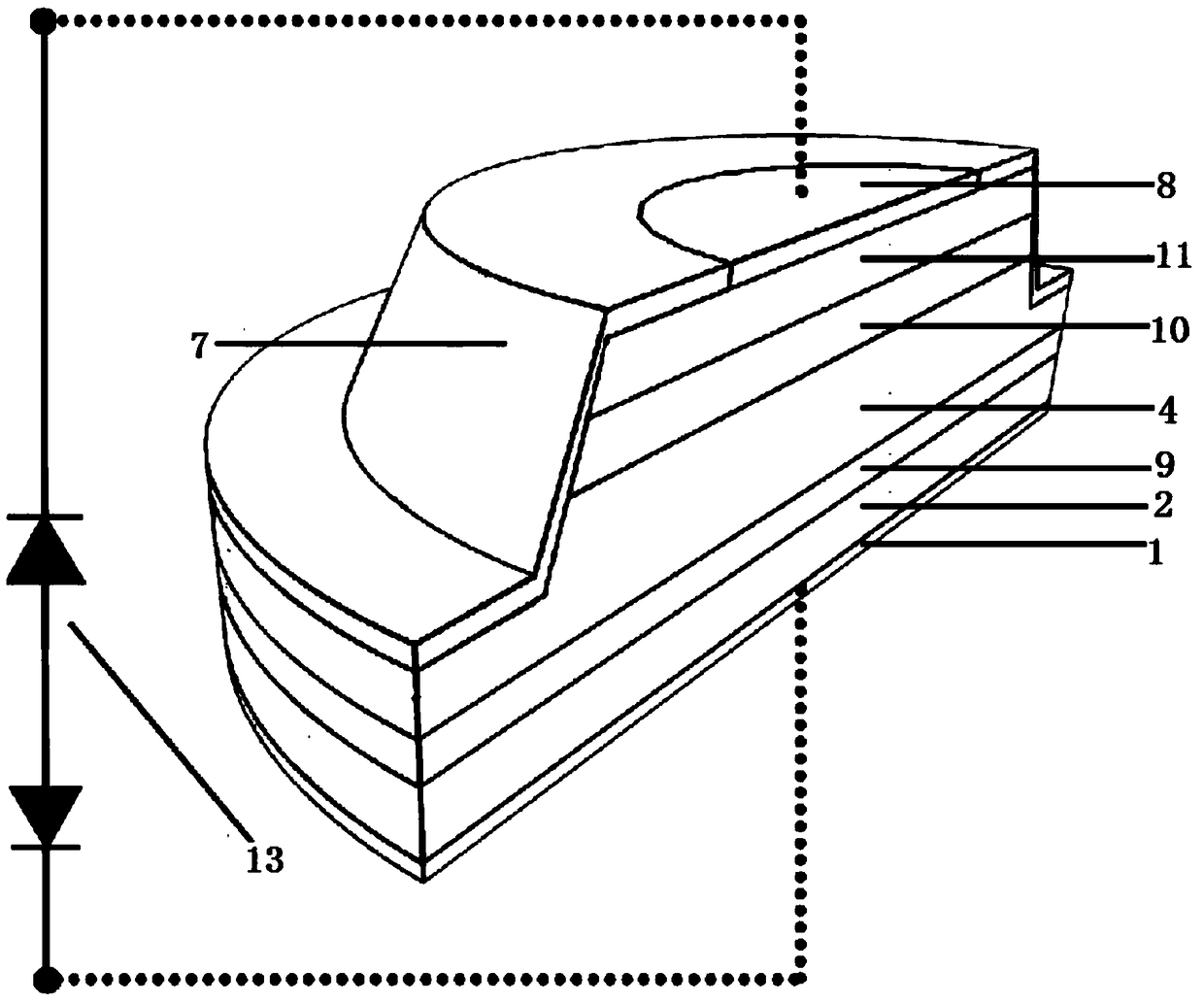

[0040] Such as image 3 As shown, using a novel n-i-p-n half-mesa vertical electrode structure, the device is fabricated on an n-type SiC substrate material. From the bottom to the top of the n-type SiC conductive substrate, there are p-type SiC transition layer, i-type SiC avalanche layer, n-type SiC transition layer, and n+ type SiC contact layer; the mesa only needs to be etched below the n-type transition layer, and the mesa The bottom is on the i-type SiC avalanche layer. The lower metal contact electrode is covered on the n-type SiC conductive substrate, and the upper metal contact electrode is on the n+ type SiC contact layer.

Embodiment 2

[0061] Basically the same as Embodiment 1, the difference is: the n-type contact electrode (lower metal contact electrode) and the p-type contact electrode (upper metal contact electrode) of the detector are all multilayer structures based on metal Ni and Au: Ni / Ti / Al / Au35 / 50 / 200 / 100nm, the Ni layer of the upper metal contact electrode is in contact with the n+ type SiC contact layer, and the Ni layer of the lower metal contact electrode is in contact with the n-type conductive SiC substrate. Compared with simple Ni / Au alloy electrodes, Ni / Ti / Al / Au composite electrodes have better ohmic contact quality, smaller specific contact resistance and lower reverse leakage current.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com