Pita bread screw rod material extruder

A bread and screw technology, applied in dough processing, baking, food science, etc., can solve the problems of uneven discharge, no discharge, uneven extrusion of fillings, etc., to avoid uneven filling and broken materials, The effect of ensuring health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

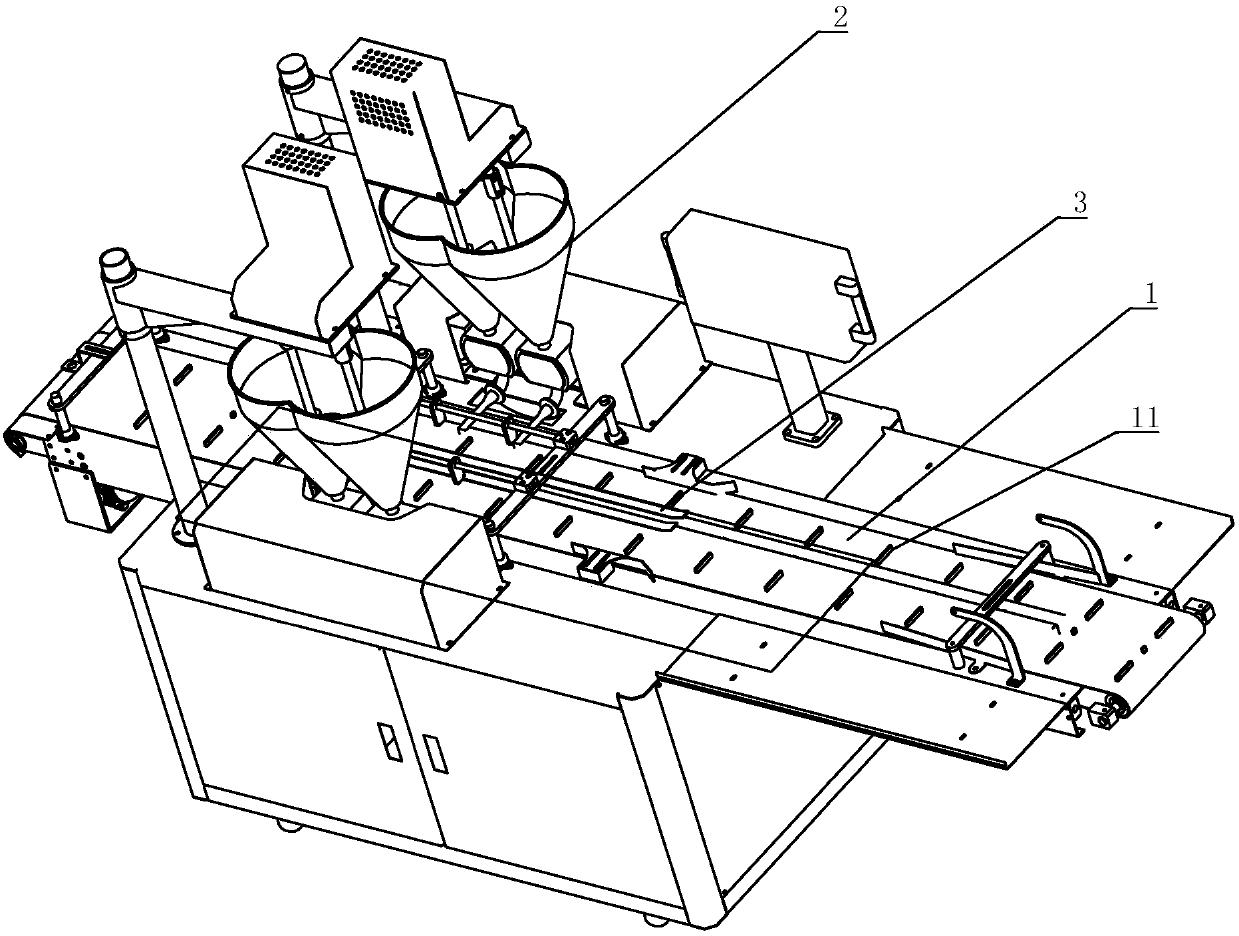

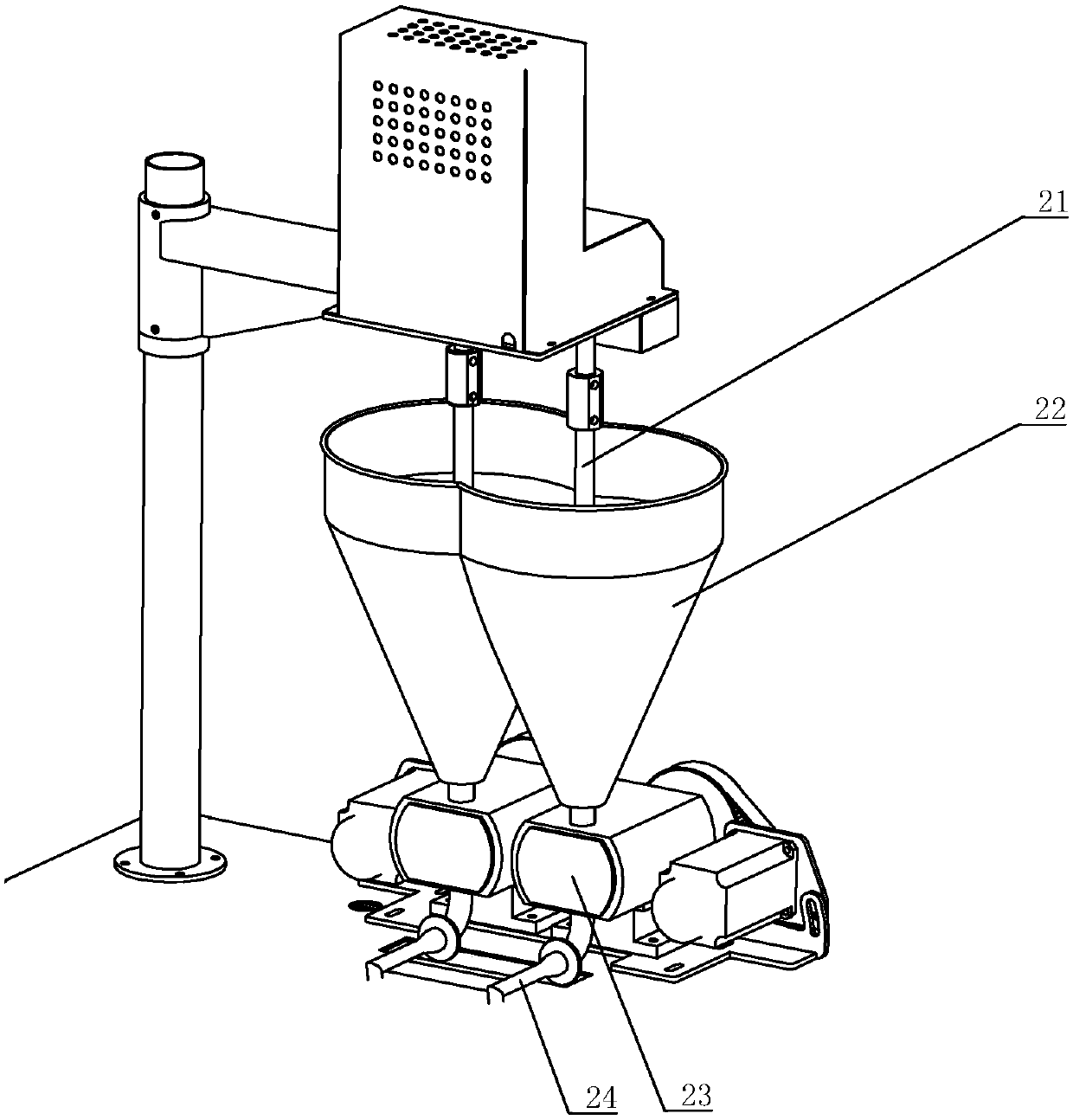

[0015] refer to Figure 1 to Figure 2 , a pocket bread screw extruder of the present invention, said screw extruder comprises a second conveyor belt 1, an extruding device 2 installed on one side of the second conveyor belt 1 and a stretching device, said extruding device 2 includes a hopper 22 and a filling cylinder 23, the filling cylinder 23 is arranged under the hopper 22 and connected to the outlet of the hopper 22, the center of the hopper 22 is provided with a screw 21 to extrude the filling to the filling cylinder 23, and the injection A filling screw is installed inside the filling cylinder 23, and the filling screw is connected to a second motor. The filling cylinder 23 is provided with a discharge pipe 24, and the stretching device stretches two slices of bread for the discharge pipe 24 to be squeezed into. There are two described hoppers 22, and they are spliced together to form a cavity. Correspondingly, there are also two discharge pipes 24, and the stretched l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com