Cross flow filtration control method, cross flow filtration device and cross flow filtration system

A technology of cross-flow filtration and control method, which is applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc. It can solve the problems that ceramic membranes cannot be fully reflected, can not be achieved, and the filtration time can be extended, so as to achieve high market promotion value , good equipment value, and the effect of prolonging the cross-flow filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

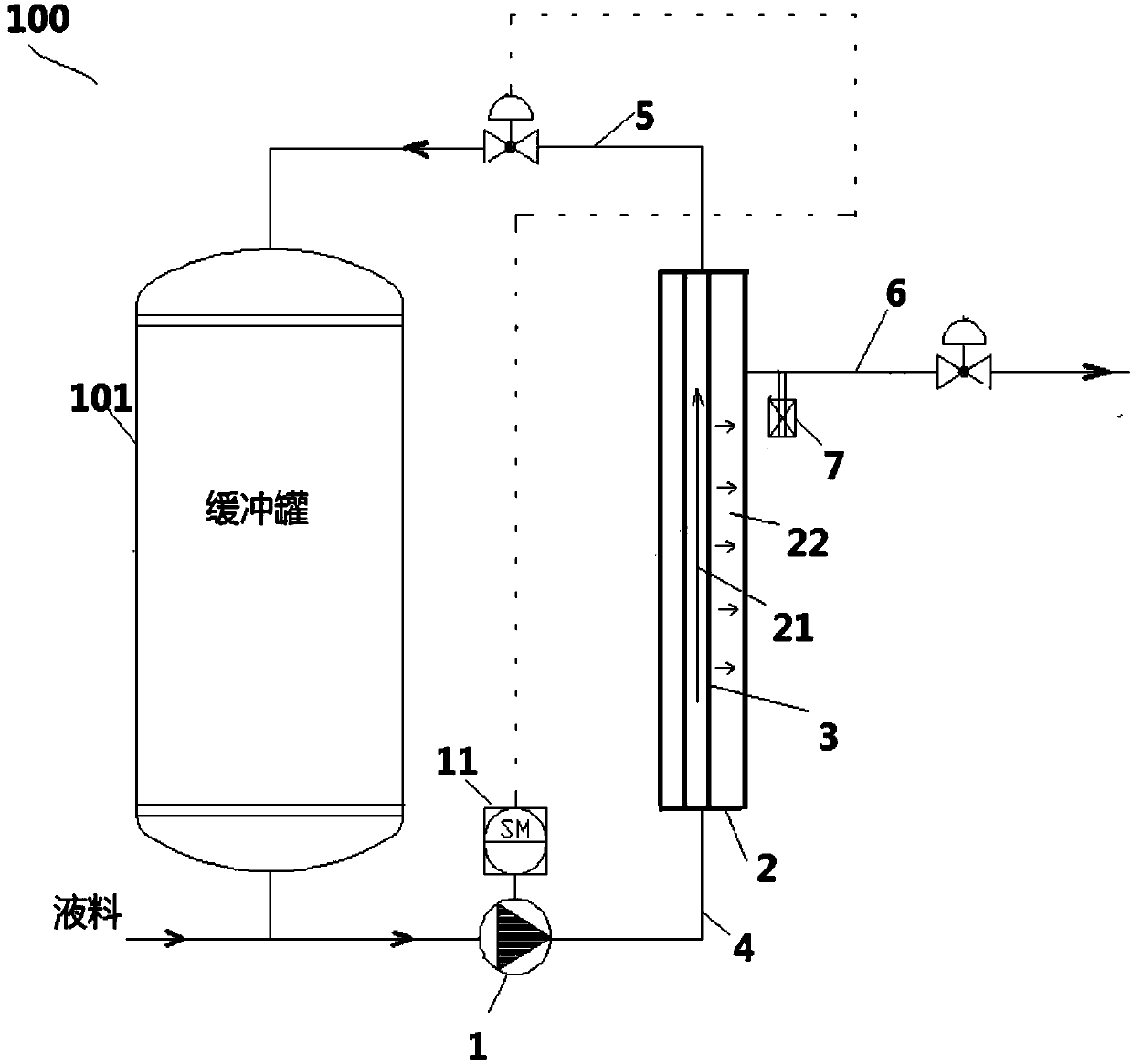

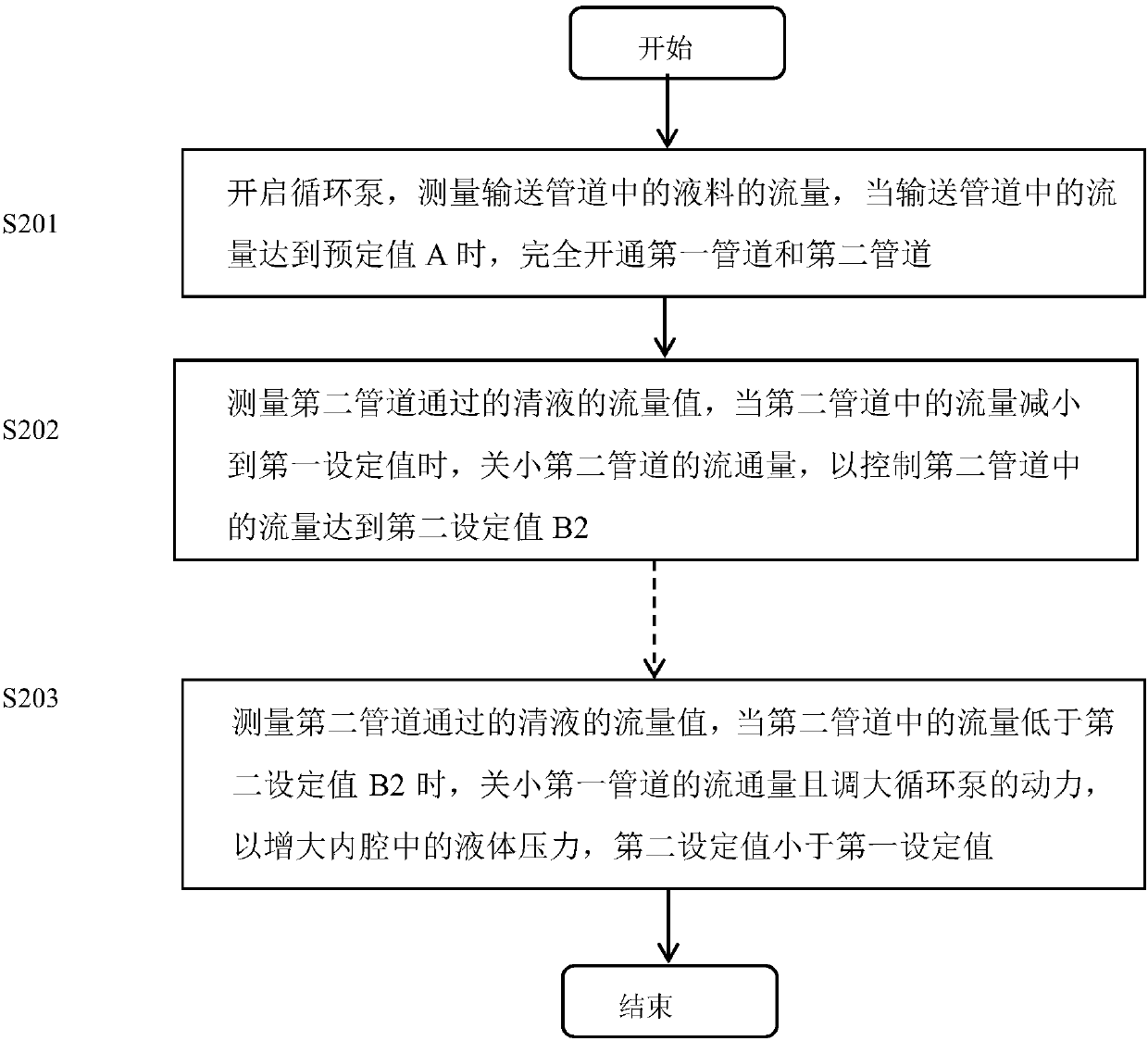

[0032] as attached figure 1 As shown in , the first embodiment of the present invention provides a cross-flow filtration control method for controlling a cross-flow filtration device 100. The cross-flow filtration device 100 includes a buffer tank 101, a circulation pump 1 and a filter chamber 2. The filter chamber 2 A cross-flow filter membrane 3 is provided in the center, and the cross-flow filter membrane 3 isolates the filter cavity 2 into an inner cavity 21 and an outer cavity 22, and the circulating pump 1 continuously sends the liquid material to be filtered in the buffer tank 101 through the delivery pipe 4 In the inner cavity 21, the remaining liquid material after filtration flows back to the buffer tank 101 through the first pipeline 5 from the inner cavity 21, and the filtered clear liquid is contained in the outer cavity 22 and output through the second pipeline 6, as shown in the attached figure 2 As shown in, the cross-flow filtration control method of the pres...

no. 2 example

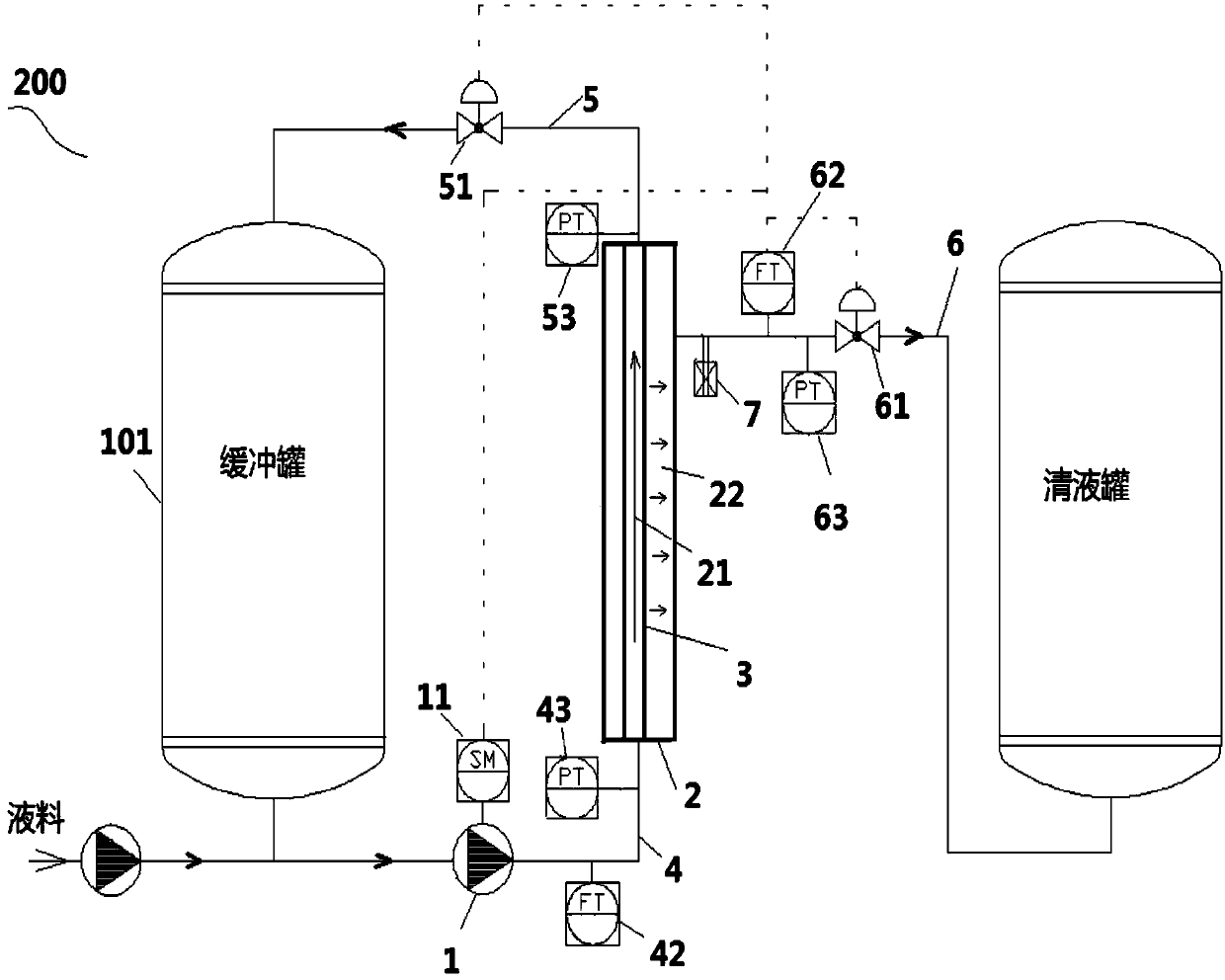

[0045] The present invention also provides a cross-flow filtration device 200, such as image 3 As shown in , including a buffer tank 101, a circulation pump 1 and a filter chamber 2, the filter chamber 2 is provided with a cross-flow filter membrane 3, the cross-flow filter membrane 3 isolates the filter chamber into an inner chamber 21 and an outer chamber 22, and the circulation pump 1 The liquid material to be filtered in the buffer tank 101 is continuously sent into the inner cavity through the delivery pipeline 4, and the remaining liquid material after filtering flows back to the buffer tank 101 through the first pipeline 5 from the inner cavity 21, and the clear liquid obtained by filtering Accommodated in the outer cavity 22 and output through the second pipeline 6, the delivery pipeline 4 is provided with a delivery flowmeter 42 for measuring the flow rate of the liquid material in the delivery pipeline, and the first pipeline 5 is provided with a flowmeter for adjust...

no. 3 example

[0056] The present invention also provides a cross-flow filtration system, including the above-mentioned cross-flow filtration device 200 and a controller 300, such as Figure 4 As shown in , the controller 300 includes a receiving module 301, a sending module 302 and an operating module 303. The operating module 303 is provided with a predetermined value A, a first set value B1 and a second set value B2. The filtering process of the filtering device 200 is controlled, specifically:

[0057] Turn on the circulating pump, the receiving module 301 receives the signal from the delivery flow meter 42, and when the liquid flow in the delivery pipeline 4 reaches a predetermined value A, the sending module 302 sends a signal to the first regulating valve 51 and the second regulating valve 61 to fully open the first regulating valve 51 and the second regulating valve 61. A regulating valve 51 and a second regulating valve 61;

[0058] The receiving module 301 receives the signal from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com