Forming equipment of transparent diamond-embedded floor board and manufacturing method of transparent diamond-embedded floor board

A molding equipment and diamond-inlaid technology, which is applied in the field of molding equipment for transparent diamond-inlaid floors, can solve the problems of low production efficiency of artistic aesthetic floors and inability to integrate other materials at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0293] Embodiments of the present disclosure will now be described in detail with reference to the accompanying drawings. Reference will now be made in detail to the preferred embodiments of the present disclosure, examples of which are illustrated in the accompanying drawings. Wherever possible, the same numbers will be used throughout the drawings to refer to the same or like parts. In addition, although the terms used in this disclosure are selected from well-known and commonly used terms, some terms mentioned in this disclosure may be selected by the applicant according to his or her judgment, and their detailed meanings are set out in this article described in the relevant section of the description. Furthermore, it is required that the present disclosure be understood not only by the actual terms used, but also by the meaning implied by each term.

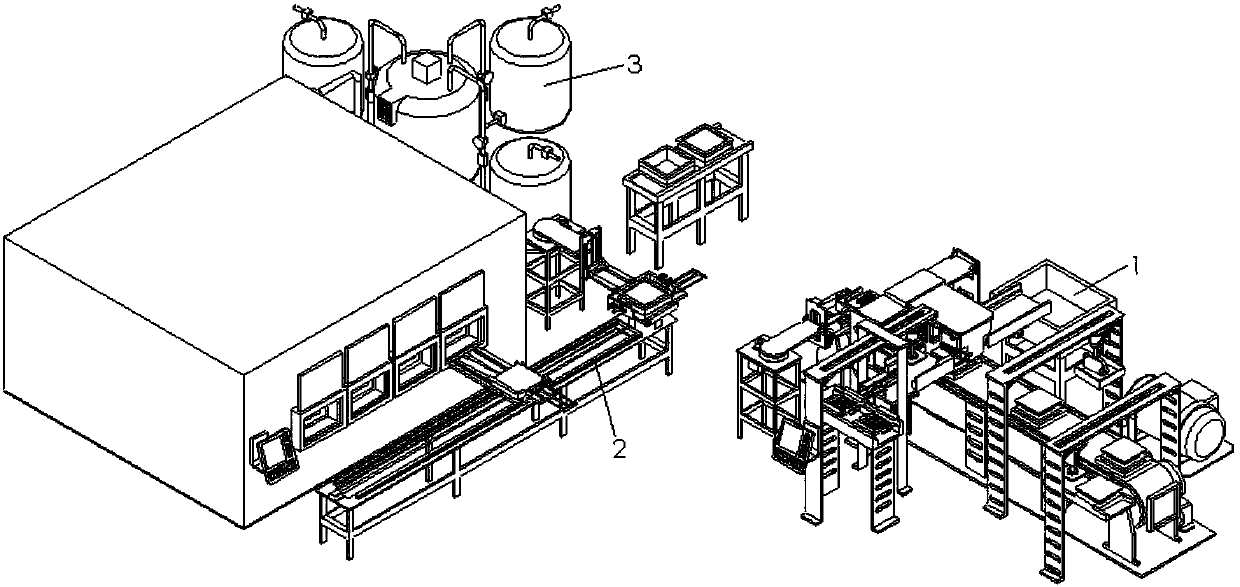

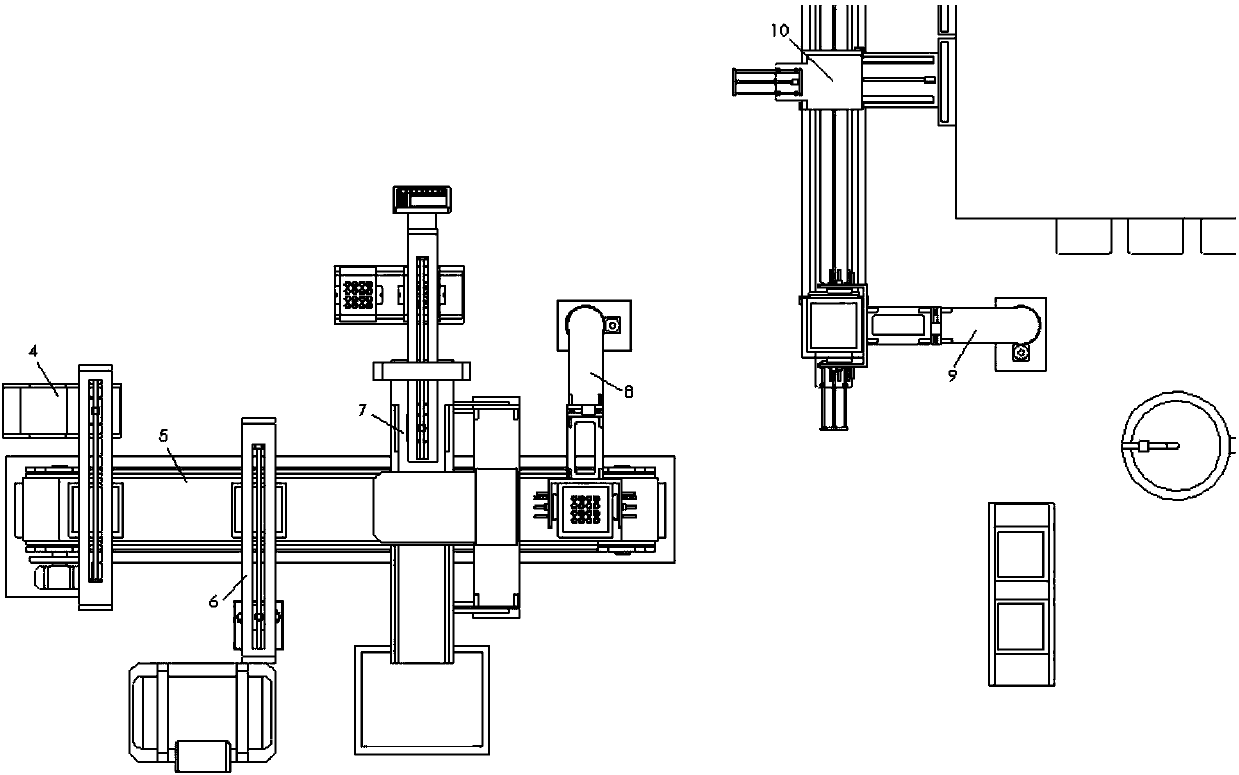

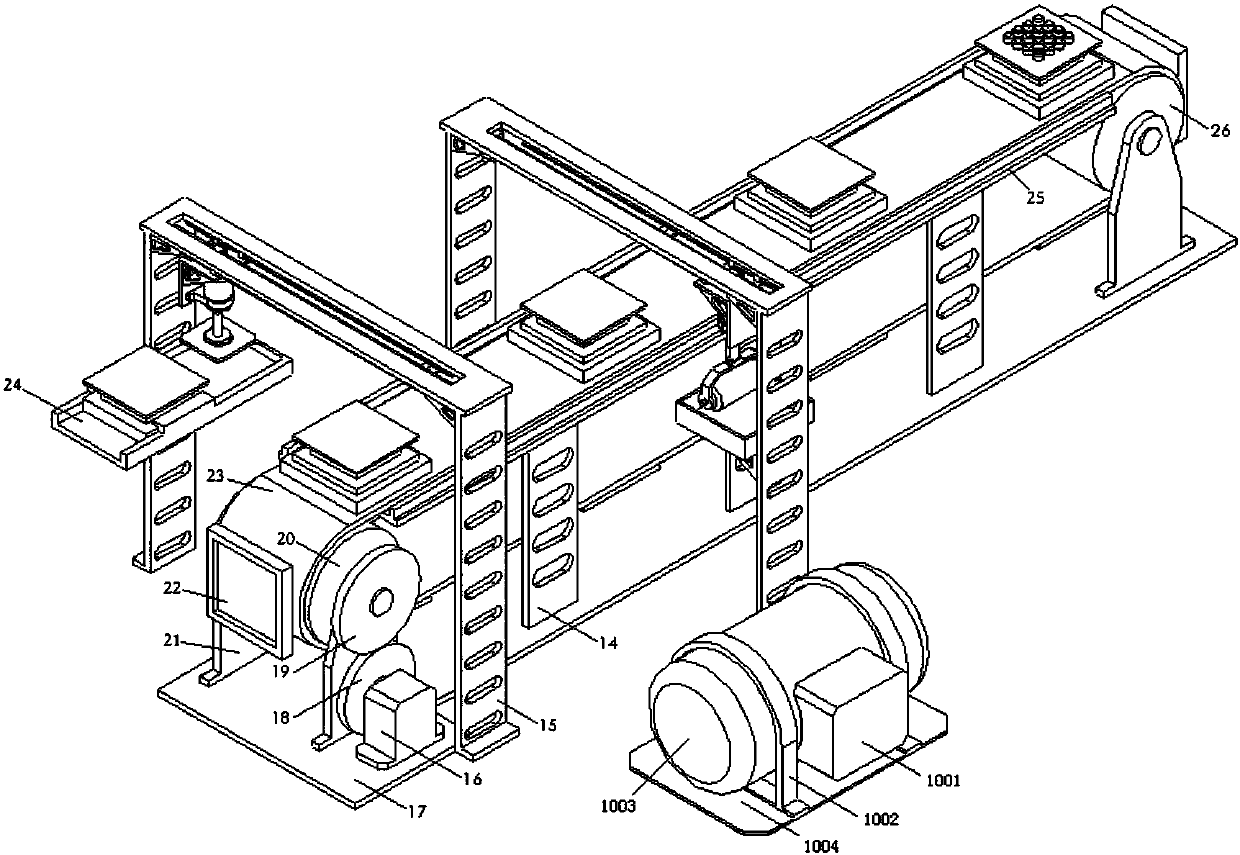

[0294] as the picture shows, Figure 1-22 as shown in figure 1 As shown, a molding equipment for a transparent diamond-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com