A method for preparing bipolar membranes by electrospinning

An electrospinning method and bipolar membrane technology, which is applied in the field of bipolar membrane preparation, can solve the problems of cumbersome preparation process, non-interpenetration of membrane layers, and difficult operation, and achieve high water dissociation efficiency, low transmembrane voltage, and reduced The effect of transmembrane voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

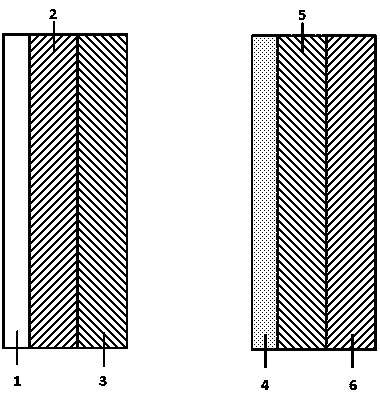

Image

Examples

Embodiment 1

[0033] Sulfonated polyethersulfone (SPES) / quaternized polysulfone (Q-PSf) nanofibrous bipolar membrane was prepared by electrospinning. Specific steps are as follows:

[0034] 1. Preparation of Dense Layer of Cation Exchange Membrane

[0035]Sulfonated polyethersulfone (SPES) was dissolved in N,N-dimethylformamide (DMF) to prepare a 10% SPES / DMF solution. The above solution was fully stirred until the SPES was completely dissolved, and the solution was filtered with a 300-mesh stainless steel mesh, and degassed under reduced pressure to obtain a viscous film solution. Adjust the slit width of the scraper to 200um, and scrape and coat on a clean glass plate to form a film. Air-dry at room temperature and release from the mold with methanol. Dry naturally the dense layer of the cation exchange membrane.

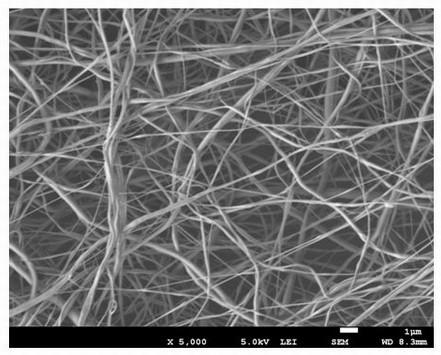

[0036] 2. Preparation of Cationic Nanofiber Membranes by Electrospinning

[0037] Dissolve SPES in a mixed solvent of DMF and methanol, and adjust the concentration of the...

Embodiment 2

[0048] Chitosan (CS) / sodium alginate (SA) nanofibrous bipolar membranes were prepared by electrospinning. Specific steps are as follows:

[0049] 1. Preparation of Dense Layer of Anion Exchange Membrane

[0050] Chitosan (CS) was dissolved in acetic acid / water solution with a volume fraction of 2%, and a chitosan acetic acid aqueous solution with a mass volume concentration of 4% was prepared. The above solution was fully stirred until the CS was completely dissolved, and the solution was filtered through a 300-mesh stainless steel mesh, and degassed under reduced pressure to obtain a viscous film solution. Adjust the slit width of the scraper to 1000um, and scrape and coat on a clean glass plate to form a film. Air-dry at room temperature and remove the mold with deionized water. Naturally dry the obtained dense layer of anion exchange membrane.

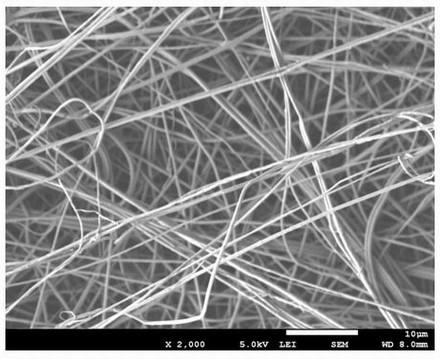

[0051] 2. Preparation of anionic nanofibrous membranes by electrospinning

[0052] Dissolve chitosan (CS) and polyvinyl alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com