Exhaust pipe installation support

A technology for installing brackets and exhaust pipes, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., can solve the problems of large vibration, loud noise, and broken exhaust pipes, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

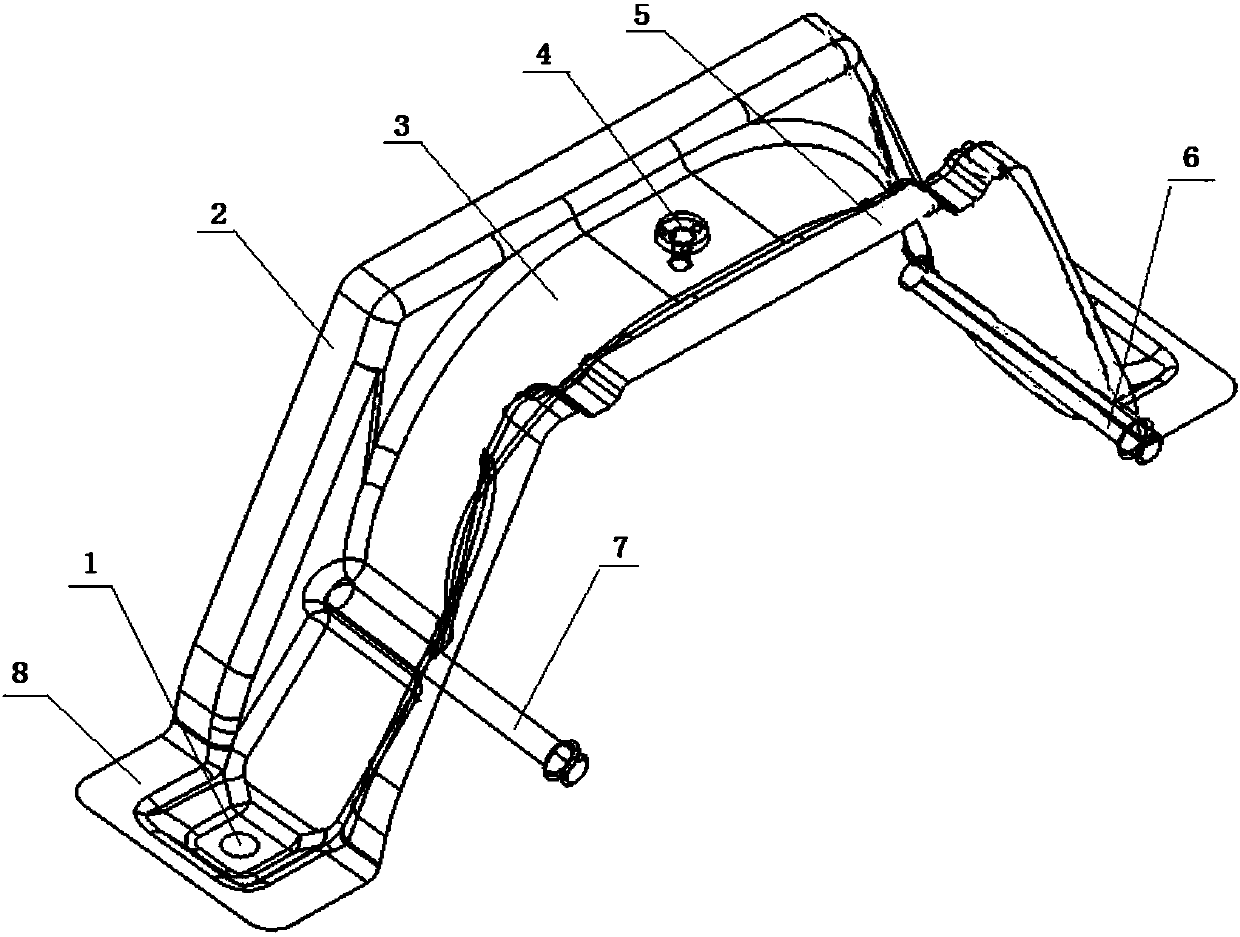

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0013] An exhaust pipe installation bracket, including an arc-shaped support plate 3, the end of the arc-shaped support plate is integrally formed with a radial fixing seat 8, and a fixing hole 1 is formed on the fixing seat, which is used to fix the beam with the rear of the frame Fixed to each other, the two arc-shaped sides of the arc-shaped support plate are uniformly equipped with radially reinforced anti-collision guards 2 and 5, and the two reinforced anti-collision plates can increase the radial length of the arc-shaped support plate to prevent the collision on the ground. High obstacles hit the curved support plate and damage the exhaust pipe.

[0014] An extended fixed rod 6 and 7 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com