Drag grinding test bench for locomotive main axle detection

A test bench and spindle technology, applied in railway vehicle testing and other directions, can solve problems such as locomotive damage, increase labor costs, locomotive failure, etc., and achieve the effect of easy judgment of the fault point, detailed and accurate measurement, and good detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

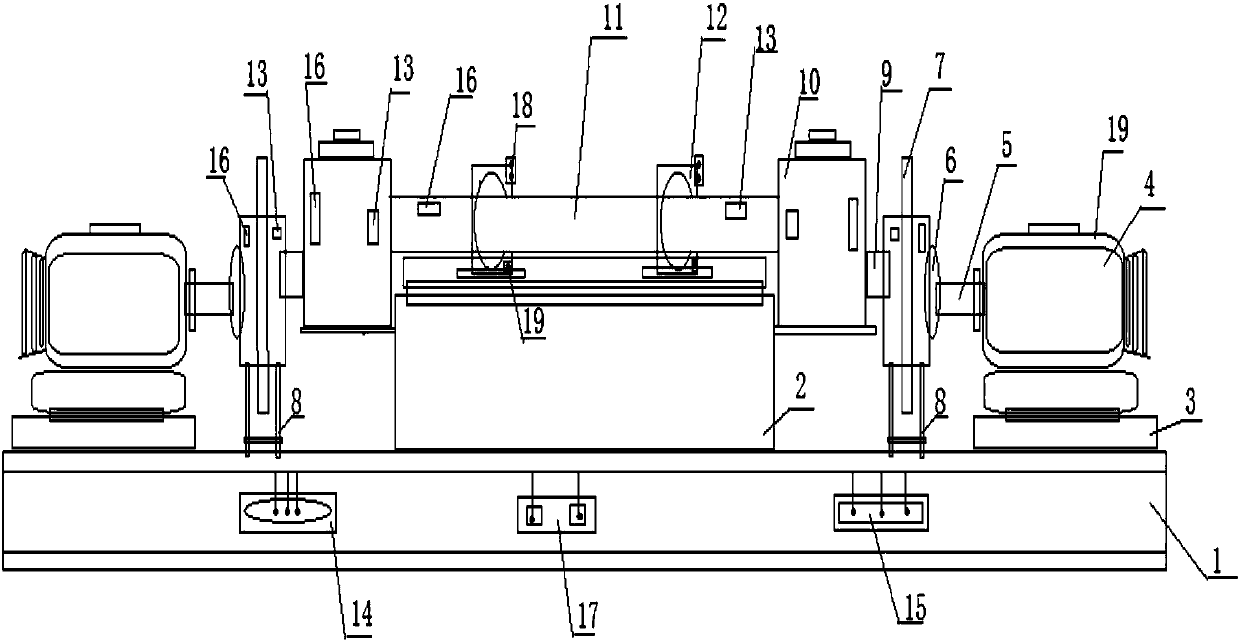

[0020] In the following, the technical solution of a dragging test bench for locomotive main shaft detection provided by the present invention will be further described in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

[0021] see figure 1 , a dragging test bench for locomotive spindle detection provided by the present invention, comprising a base 1 arranged horizontally, a spindle mounting table 2 arranged in the center of the base, motor adjustment seats 3 are symmetrically arranged on both sides of the base 1, and the motor adjustment A frequency conversion motor 4 is fixedly arranged on the seat 3, and the frequency conversion motor 4 is connected with one end of the power transmission shaft 5, and the other end of the power transmission shaft 5 is connected with the wheel shaft 7 through the flange 6, and the wheel shaft 7 is fixed by the wheel axle frame 8, and the wheel shaft 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com