Automatic production equipment for paint spraying of heels of high-heeled shoes and production method

A technology for production equipment and high-heeled shoes, applied in spray booths, spray devices, coatings, etc., can solve problems such as low work efficiency, inconvenience, and environmental pollution, and achieve the goal of ensuring air cleanliness, uniform spraying, and reducing paint mist pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

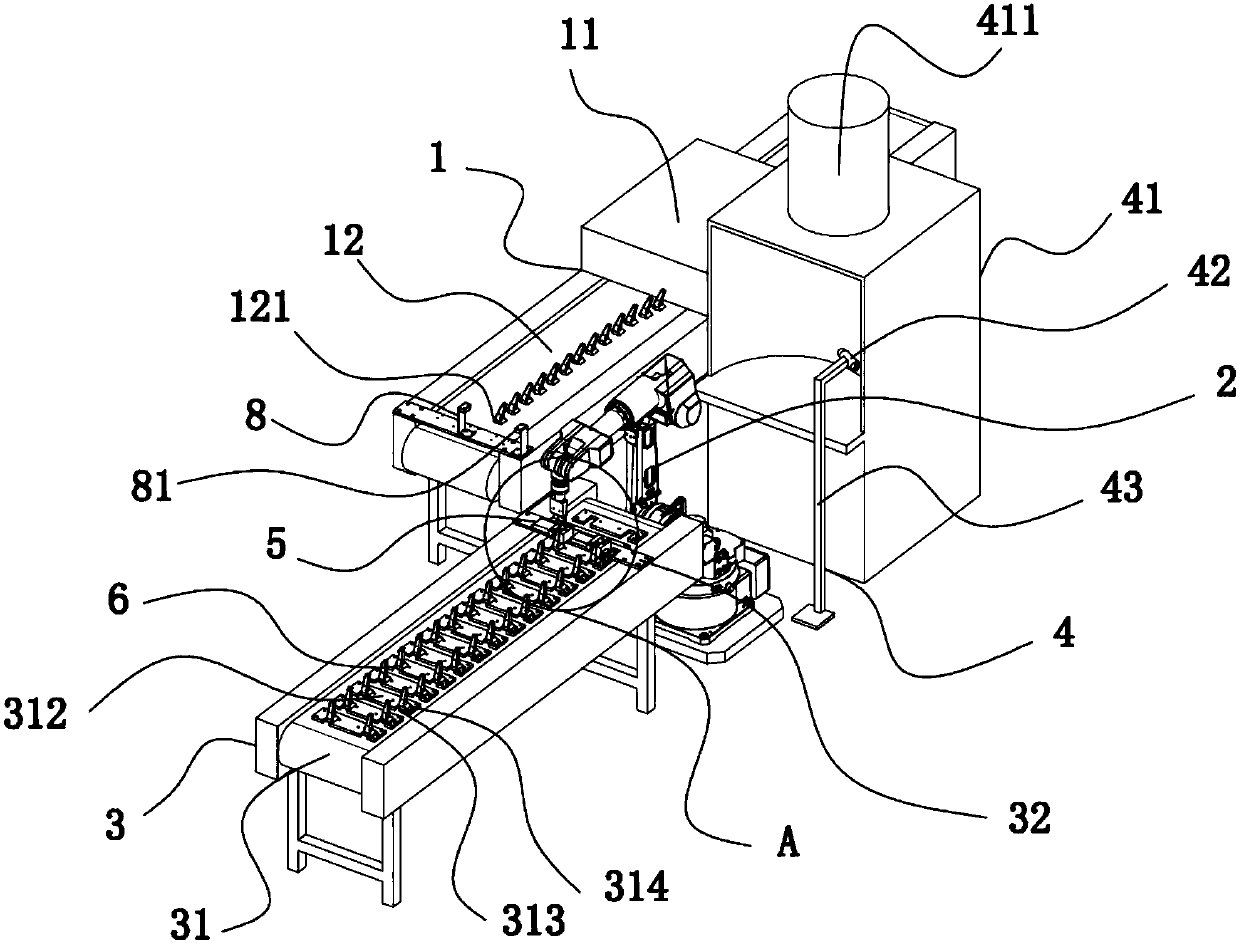

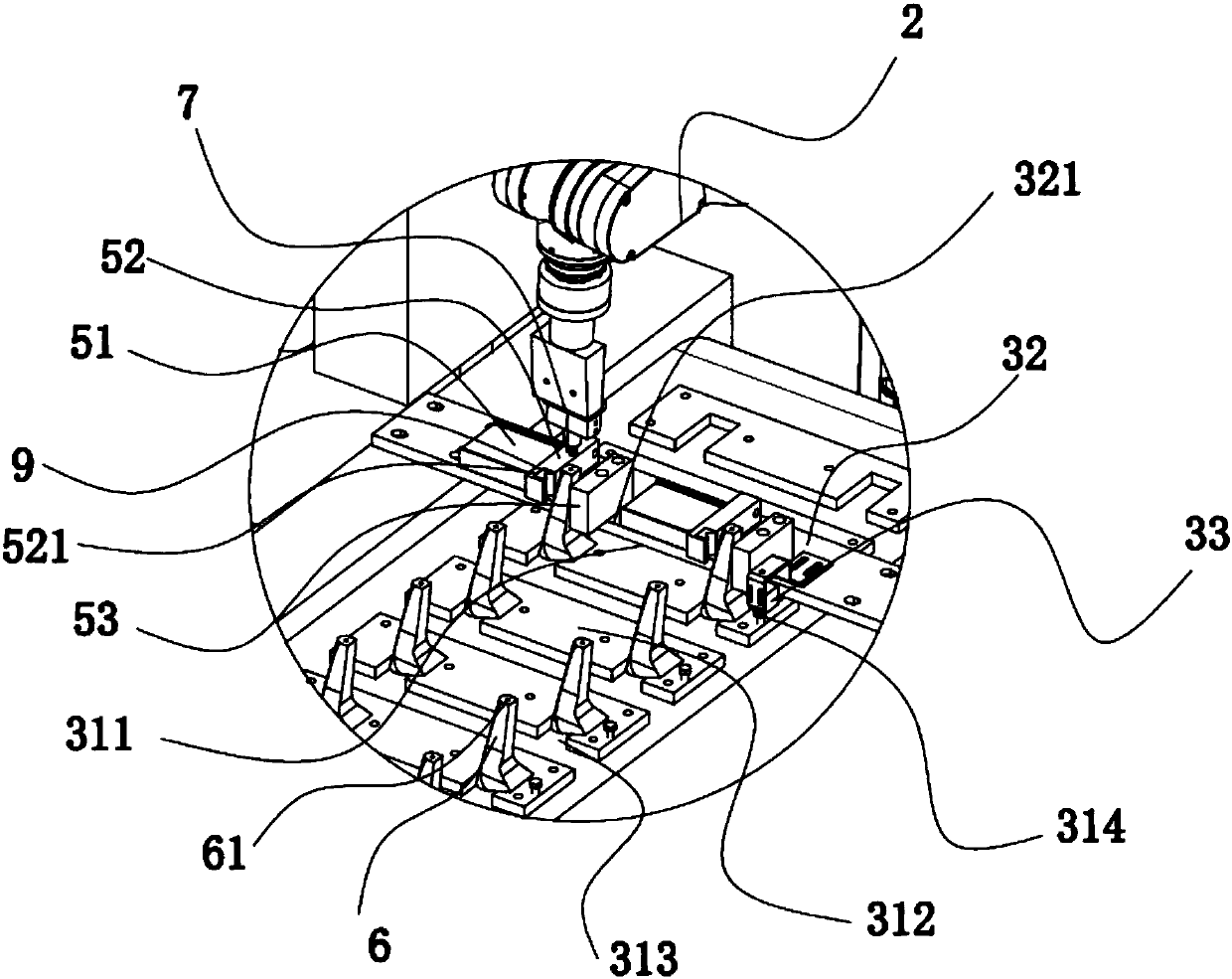

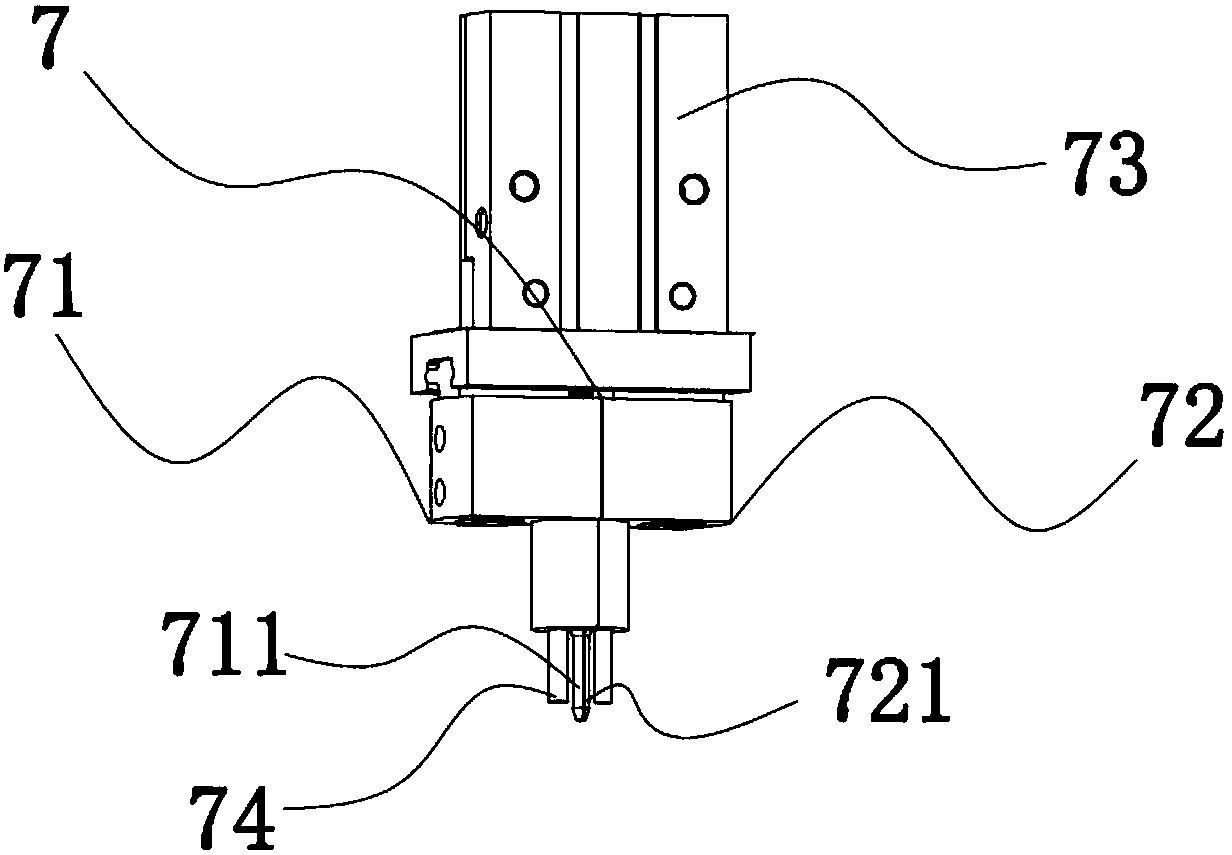

[0026] Embodiment one: if figure 1 As shown, a kind of high-heeled shoes heel painting automatic production equipment according to the present invention includes a drying equipment 1, and is characterized in that: it also includes a six-axis joint robot 2, a feeding mechanism 3 and a painting device 4, and the drying The equipment 1, the six-axis joint robot 2, the feeding mechanism 3 and the painting device 4 are all coordinated and controlled by PLC, and the six-axis joint robot 2 is set in the middle of the feeding mechanism 3, the painting device 4 and the drying equipment 1, The feeding mechanism 3 includes a feeding conveyor belt 31 and a material discharging grabbing fixed frame 32, and the described discharging grabbing fixed frame 32 is arranged across the top of the discharging end 311 of the feeding conveyor belt. A plurality of heel stoppers 312 are equidistantly arranged on the belt 31, and two left and right symmetrical heel placement grooves 313 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com