Clamp with firm clamping effect for machining of screw moulds

A mold processing and firm technology, applied in the direction of clamping, workpiece clamping devices, metal processing equipment, etc., can solve the problems of not being able to respond well to the clamping situation and the clamping effect is not ideal, so as to achieve the goal of not being easily deformed and convenient Adjust the clamping force, not easy to loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

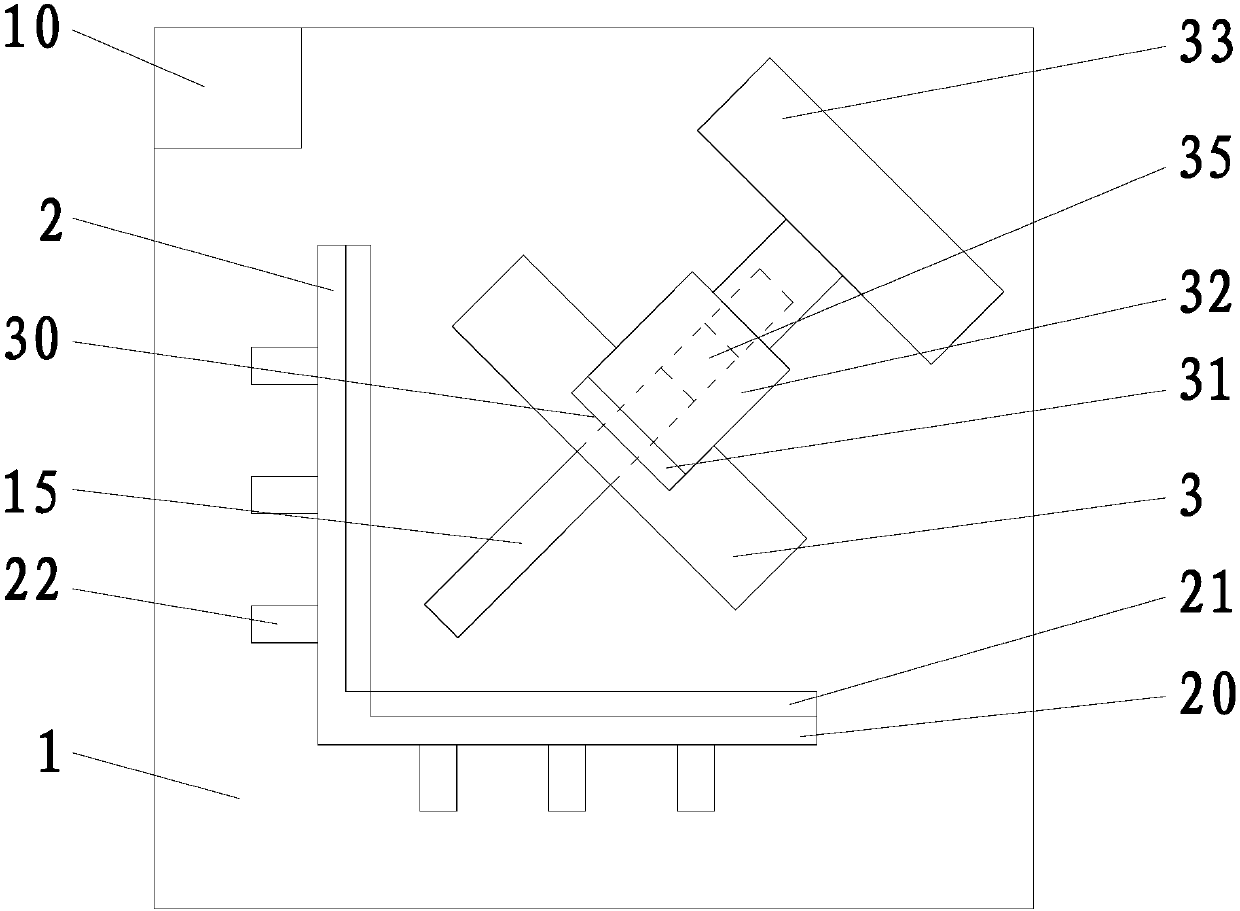

[0014] refer to figure 1 , the present invention is a fixture for screw mold processing with firm clamping, comprising a main body plate 1, a first fixed plate 2, a second fixed plate 20, a movable plate 3, a push-pull rod 32, a push-pull device 33, a pressure sensor 31, a control In the device 10, a first fixed plate 2 and a second fixed plate 20 are fixed on the main body plate 1, the first fixed plate 2 and the second fixed plate 20 form a bent structure, and the first fixed plate 2 and the second fixed plate 20 form a bent structure. A movable plate 3 is provided in the region clamped by the second fixed plate 20, and a groove 30 is provided on the side of the movable plate 3 away from the bending structure, and a pressure sensor 31 is fixed on the groove bottom of the groove 30, and the push-pull rod 32 stretches into the groove 30 and is connected with the pressure sensor 31, and the other end of the push-pull rod 32 is connected with a push-pull device 33, and the push-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com