Two-section folding conveyer automatically controlled by winch

A hoist and conveyor technology, applied in the field of two-section folding conveyors, can solve the problems of heavy weight, high cost, and large belt load margin, and achieve the effects of improving conveying efficiency, reducing load load, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

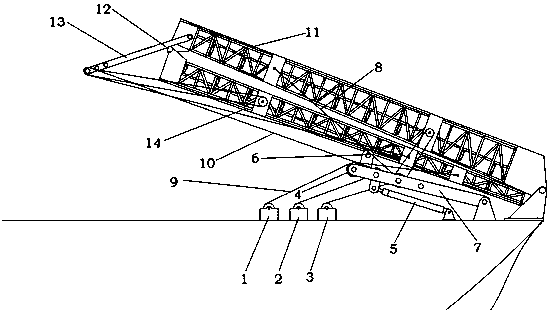

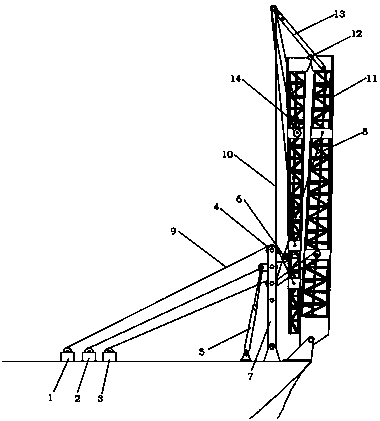

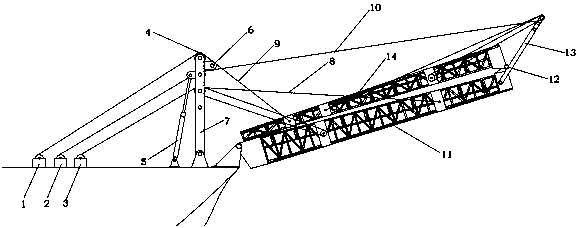

[0026] Such as figure 1 Shown, a kind of two-section folding conveyer of winch automatic control, comprises two delivery arms, main gantry 7, hoist; It is characterized in that: also comprises auxiliary gantry 13, hydraulic oil cylinder 5, limiter 12; Described The second conveying arm 11 adopts a trapezoidal truss structure, and its large end is hinged with the base installed on the hull, and its small end is hinged with the first conveying arm 14 large ends; the first conveying arm 14 and the second conveying arm 11 Idlers are evenly installed on the cross bar of the middle truss, pulleys are welded on its side, and reinforcement plates are arranged at the welding position; There is a limit device 12 composed of threaded structure and trapezoidal steps; the upper end of the main gantry is equipped with three sets of upper, middle and lower pulleys, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com