Non-porous inner barrel washing machine drainage device and method and washing machine

A technology for washing machines and drainage holes, which is applied to washing devices, other washing machines, textiles and papermaking, etc., and can solve problems such as severe shaking of output shaft sleeves and failure of water seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

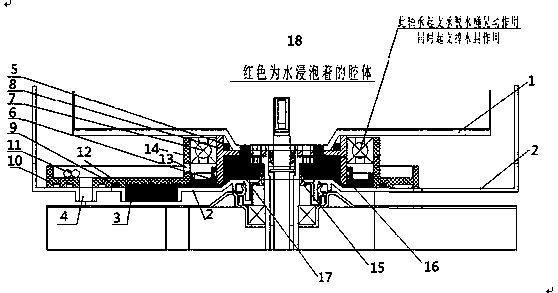

[0029] specific implementation

[0030] The drainage device of the present invention includes a support 10, a second drainage hole 4 is arranged on the support, and a water level sensor 11 is arranged at an appropriate position adjacent to the second drainage hole 4 and / or between the main drainage hole 3 and the drainage valve ,

[0031] An annular bearing outer bracket 14 is disposed at an approximate center position of the support 10 and extending upward from the upper bottom surface 12 of the support.

[0032] A connecting plate 8 is provided, the connecting plate 8 is circular, and a circular ring-shaped edge is formed around the circular connecting plate 8, and its central cross-section is "I"-shaped, and the outer side of the circular ring-shaped edge is for the bearing 7. , forming the inner support of the bearing 7, and the sealing strip 5 is arranged on the inner side of the annular edge and the upper side of the circular connecting plate.

[0033] A bearing 7 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com