Self-cleaning conveyor belt

A conveyor belt and self-cleaning technology, used in conveyors, conveyor objects, cleaning devices, etc., can solve the problems of material waste, serious wear, and affect the cleaning effect, and achieve the effect of ensuring the cleaning effect and expanding the coverage area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

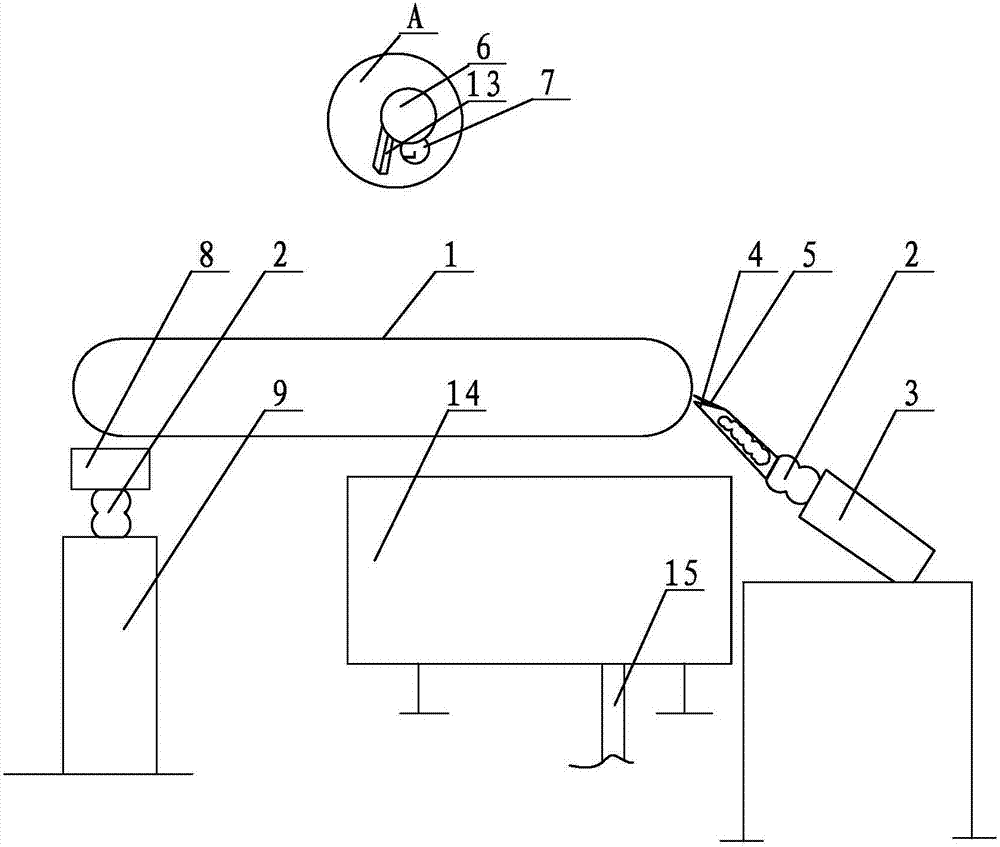

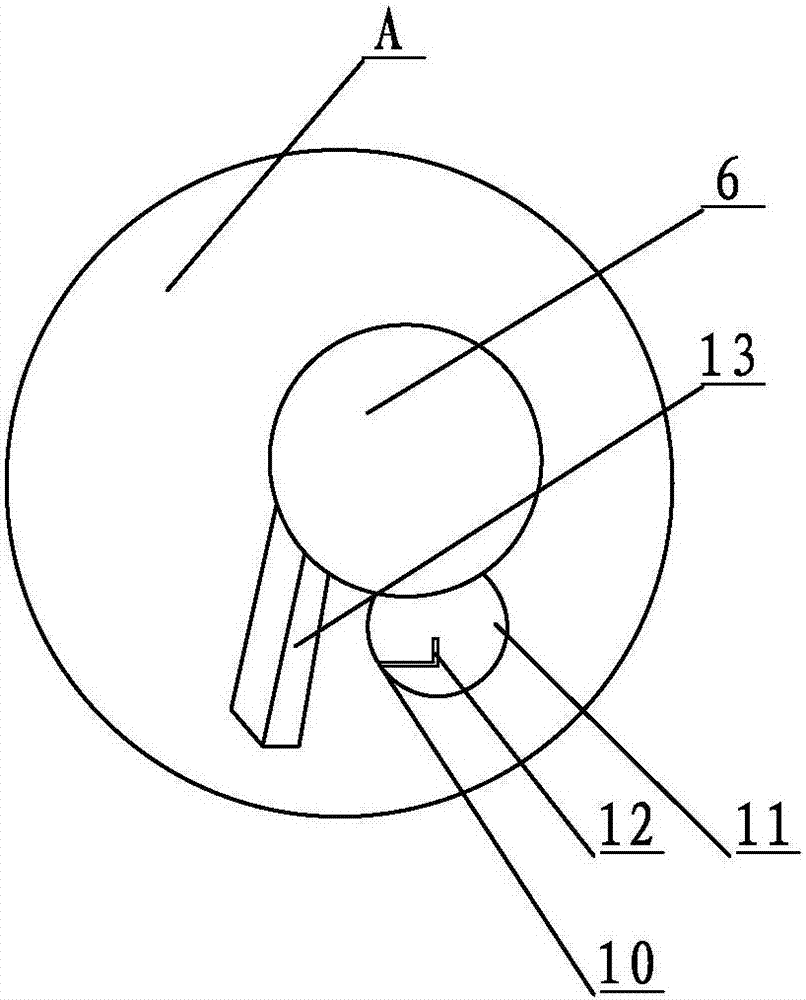

[0023] Such as Figure 1-2 As shown, the self-cleaning conveyor belt of the present invention includes a conveyor belt 1 and a plastic scraper. One end of the conveyor belt 1 is provided with a plastic scraper. A scraper drive assembly 3, a pressure sensor is set between the air spring 2 and the plastic scraper, the plastic scraper includes a primary scraper 4 and a secondary scraper 5, the primary scraper 4 and the secondary scraper 5 are set as an integral structure, so The non-bearing parts of the primary scraper 4 and the secondary scraper 5 are set as hollow structures, and a water spray pipe 6 is correspondingly arranged above the conveyor belt 1. One end of the water spray pipe 6 is connected to a high-pressure water pump, and the other end is sealed. Corresponding conveyor belt 1 is provided with nozzle 7, and described nozzle 7 comprises nozzle 10, nozzle body 11, and the two ends of nozzle body 11 are communicated with water spray pipe 6 and nozzle 10 respectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com