Rope tenon beam and slab structure

A technology of beam-slab structure and rope tenon, which is applied in the direction of building construction and construction, can solve the problems of non-denial and achieve the effect of preventing vertical separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

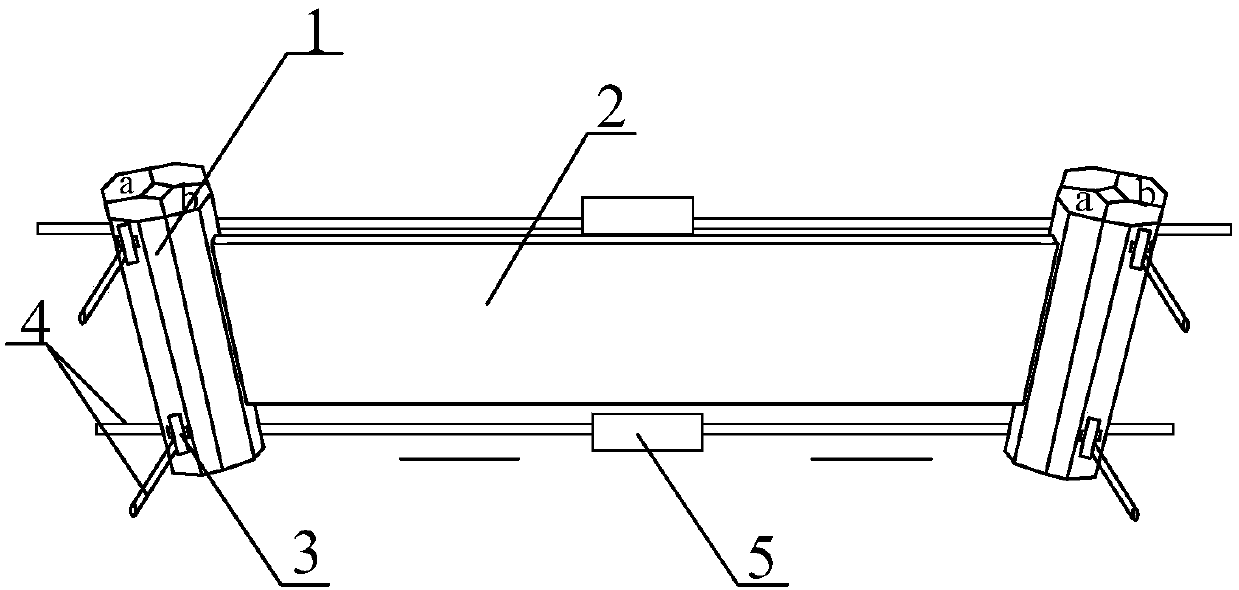

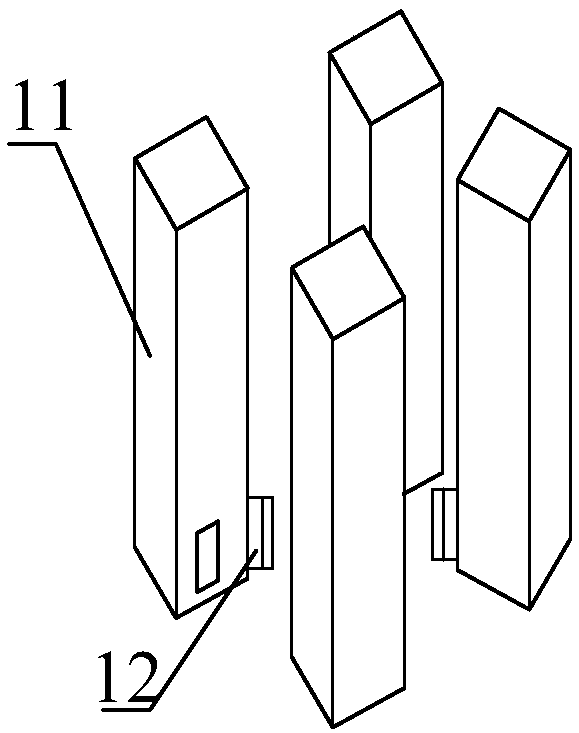

[0049] The tenon rod composed of four tenon rod components is called tenon four rod, and the single tenon rod formed by it is called tenon four rod connection body. The tenon four rod connection body is as follows image 3 As shown, the mortise and tenon components are interlocking structures, and the tenon and tenon components are provided with openings in the transverse direction, which can avoid detachment. Figure 5 One end of the rope is fixed on the mortise rod assembly, and the other end passes through its dual rod to reach the tenon rod assembly on the other side. The two tenon rods are connected to the beam. Tighten the two pairs of mortise bars together, and the tension on the mortise bars points to the center point of the mortise bars, and the tenon bars are clamped by the pulling force.

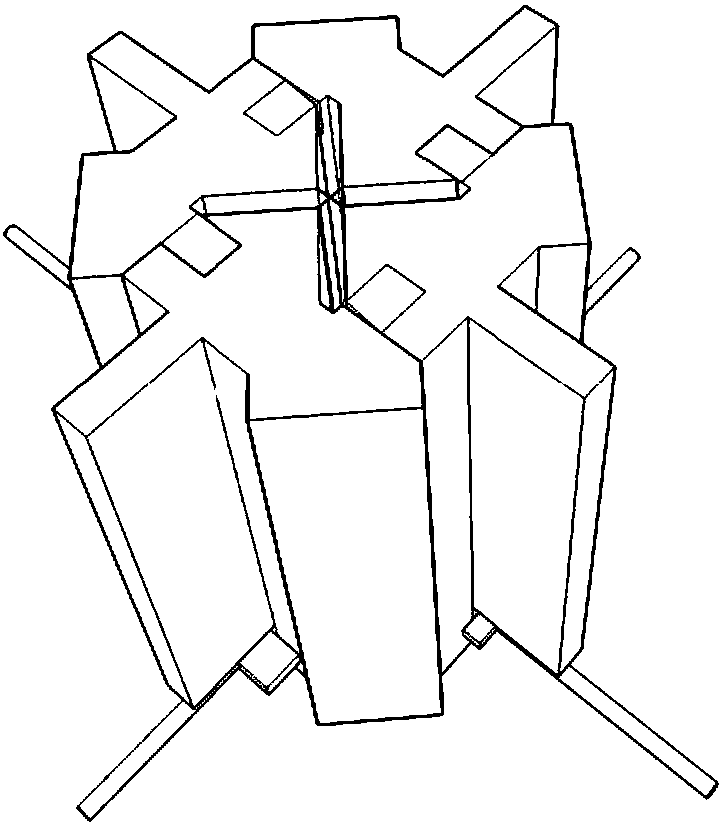

[0050] Such as Image 6 As shown in the top view of the tenon rod, the four tenon rods that make up the tenon four-bar connection have the function of limiting the opening. Tigh...

Embodiment 2

[0052] The tenon rod composed of six tenon rod components is called tenon six rod, and the single tenon rod formed by it is called tenon six rod connection body. The tenon six rod connection body is as follows Figure 8 As shown, each set of mortise rods is composed of three sets of mortise rod sets, and the single tenon six-rod connector has six ropes to pull it out. connectors, such as Figure 9 The included angle between the pulling ropes of the tenon-and-six-rod connection shown is 60 degrees. By analogy, the angles of the sharp angles of the tenon-eight-rod connection and more tenon-rod connections decrease in turn, and the tenon-six-rod connection Dowel sets are provided with matching wedge structures such as Figure 10 As shown, the mortise bar set is combined into a tenon bar set through wedge-like structure, and three sets of tenon bar sets are combined to form a tenon bar.

Embodiment 3

[0054] Such as Figure 11 The mortise and eight-bar connection body shown is composed of four sets of tenon and tenon rod sets, and each tenon and eight-bar connection body is connected with other eight identical bodies. A single tenon and tenon rod is equivalent to a network in the network of tenon and tenon rods connected into pieces node, such as Figure 12 to Figure 14 shown.

[0055] The overall tenon-rod network is composed of several tenon-rods intertwined with each other. Compared with the rigidly connected connector structure, the tenon-rod network has the advantages of light weight, easy disassembly, and uniform force transmission. It has irreplaceable advantages in many fields. For example, it can be used in Corrosion-resistant structures with strong supporting force, the outer protective structure of the building, imitating the traditional Chinese wooden structure bucket arch and caisson decoration, compared with the traditional mortise and tenon structure, the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com