Electric valve

A technology of electric valves and spools, which is applied in the direction of valve lifts, valve devices, valve details, etc., and can solve problems such as large loads of spools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

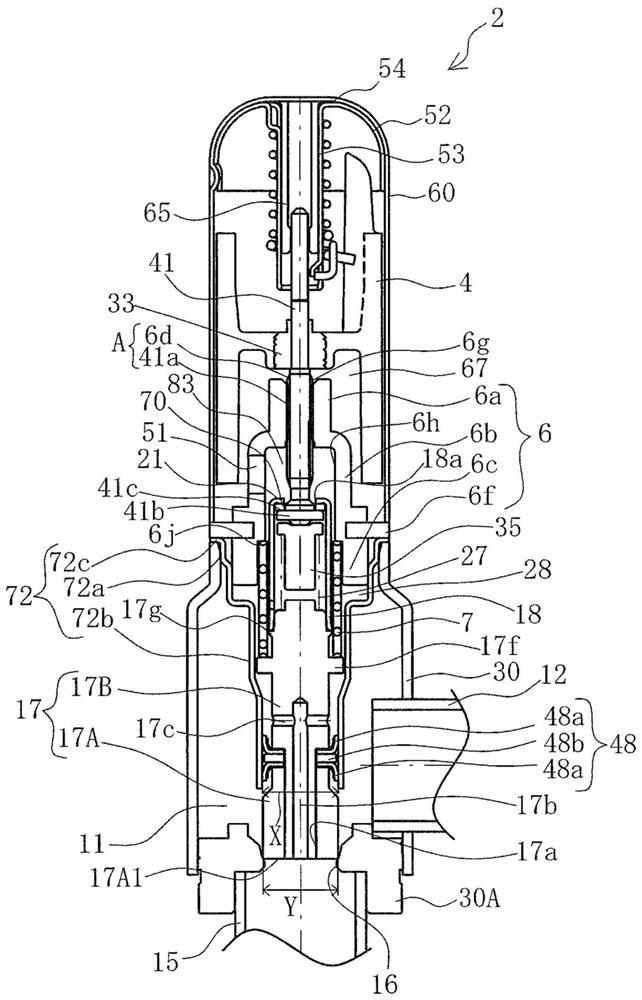

[0066] Hereinafter, an electric valve according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a sectional view showing the electric valve 2 of the embodiment. Also, in this specification, "upper" and "lower" are used in figure 1 specified in the state. That is, the rotor 4 is located above the spool 17 .

[0067] In this electric valve 2 , a valve main body 30 is integrally connected by welding or the like below the opening side of a non-magnetic cylindrical cup-shaped housing 60 .

[0068] Here, the valve main body 30 is a press-formed product produced by press-working a metal material such as a stainless steel plate, and has a valve chamber 11 inside. In addition, a first pipe joint 12 made of stainless steel or copper that directly communicates with the valve chamber 11 is fixedly attached to the valve main body 30 . Further, a valve seat member 30A having a circular cross section and having a valve port 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com