Novel extractor hood

A technology for range hood and range hood, applied in the field of range hood, can solve the problems of high mold cost, serious homogeneity, inability to open high-end market, etc., and achieve the effect of novel and unique appearance and lower mold cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

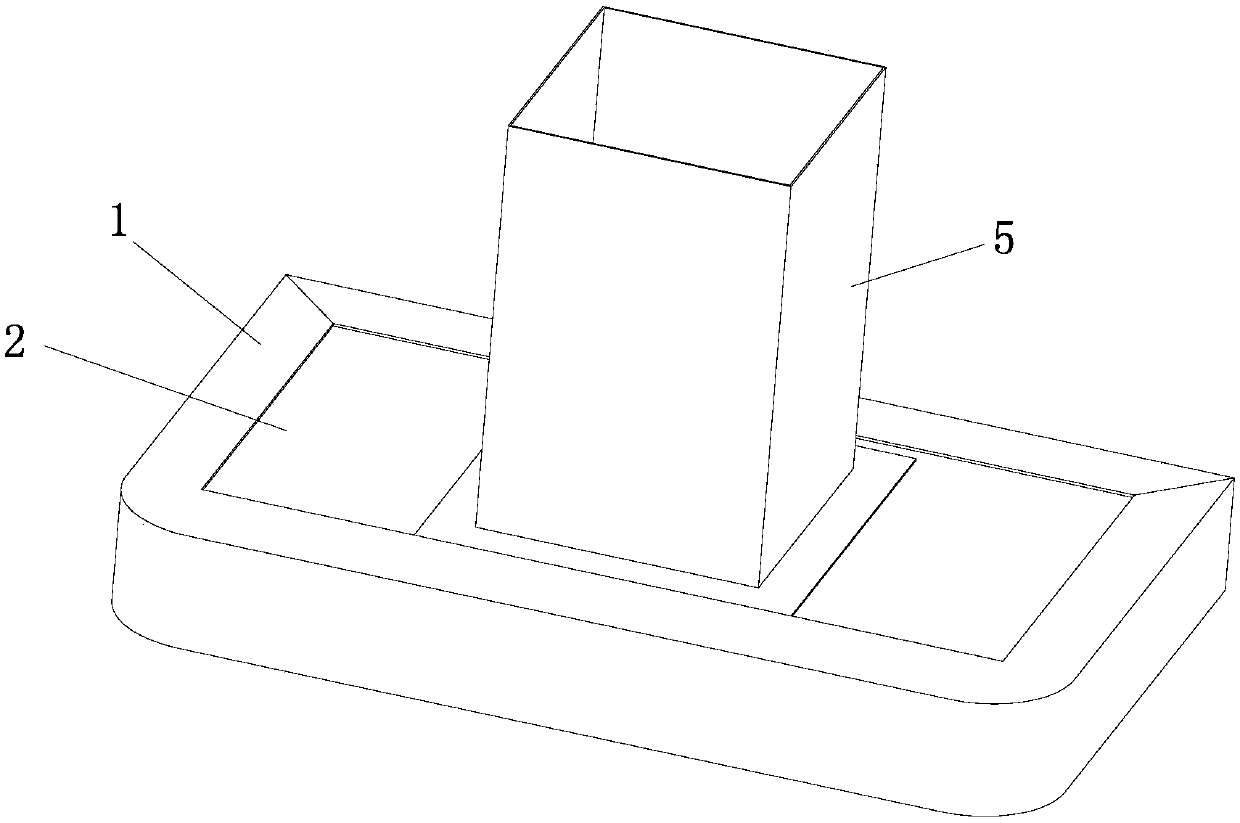

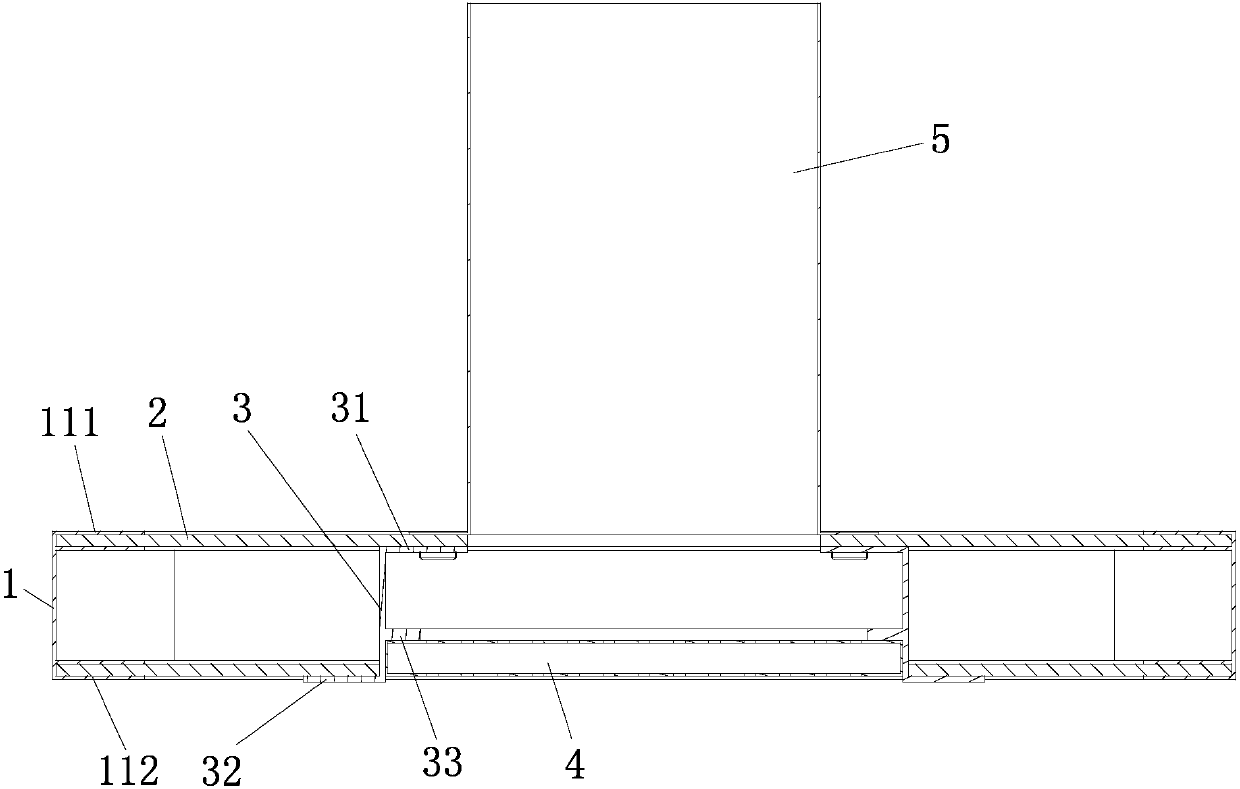

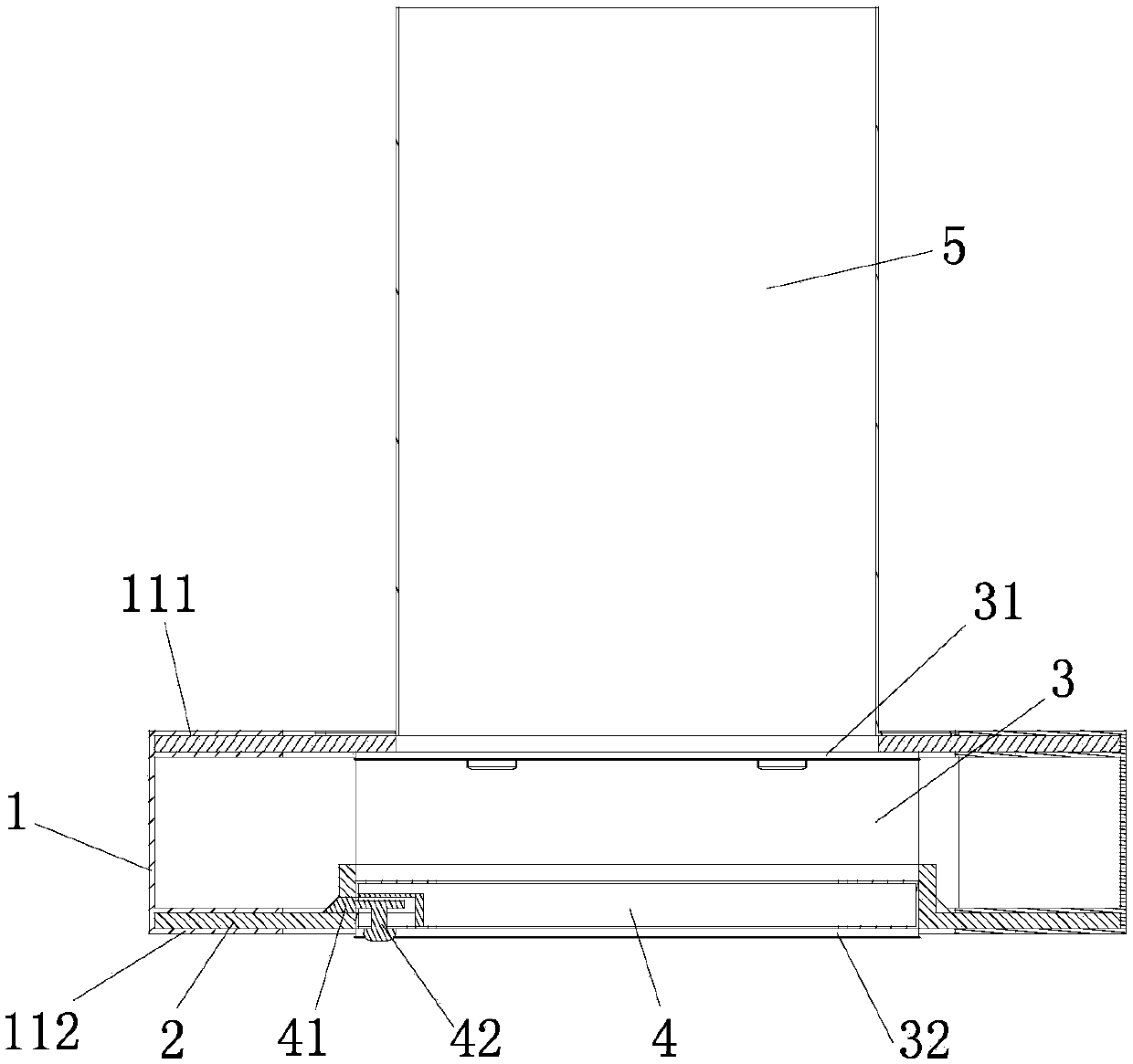

[0030] see Figure 1-6 , the new range hood includes a fume collection hood, the fume collection hood is composed of a side frame 1 and a panel 2, the panels 2 are at least two layers and arranged on the inner edge of the side frame 1 at intervals, the side frame The inner edge of the panel 1 is vertically arranged with installation positions for fixing the panel 2, and the middle part of the panel 2 constitutes the oil suction fume channel. The smoke collecting hood of the present invention is composed of a side frame 1 and upper and lower panels 2, which is different from the traditional structure formed by integral stretching and stamping of metal plates, which greatly reduces the mold cost. The side frame 1 and the panel 2. The material is changeable, such as metal, ceramic, glass, etc. can be used, and there are more processing methods and surface treatment methods. Compared with the traditional range hood, the range hood produced has a novel and unique appearance and a m...

no. 2 example

[0041] see Figure 7-8 , The difference between the present embodiment and the first embodiment of the new range hood is that the panel 2 has three upper, middle and lower layers. The insertion slot 11 assembled with the upper panel 1, the length of the upper slot body 111 protruding from the inner edge of the side frame 1 is greater than the length of the lower slot body 112 extending from the inner edge of the side frame 1; the insertion slot 11 assembled with the middle panel 1 , the length of the upper groove body 111 protruding from the inner edge of the side frame 1 is equal to the length of the lower groove body 112 extending from the inner edge of the side frame 1; the insertion groove 11 assembled with the lower panel 1, the upper groove body 111 extending out of the side frame The length of the inner edge of 1 is less than the length of the rain gutter body 112 protruding from the inner edge of the side frame 1, which can further save the cost of the side frame 1.

...

no. 3 example

[0044] see Figure 9 , The difference between this new range hood and the first embodiment is that the panel 2 is an arc-shaped panel, and the shape is further changed to meet the aesthetic requirements of more consumers.

[0045] Other unmentioned parts are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com