Equipment passive zero energy consumption freeze-proofing device based on PCM

An antifreeze device and zero energy consumption technology, which is applied in heat storage equipment, heat exchange equipment, lighting and heating equipment, etc., to achieve simple operation and maintenance, improved environmental adaptability and durability, and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

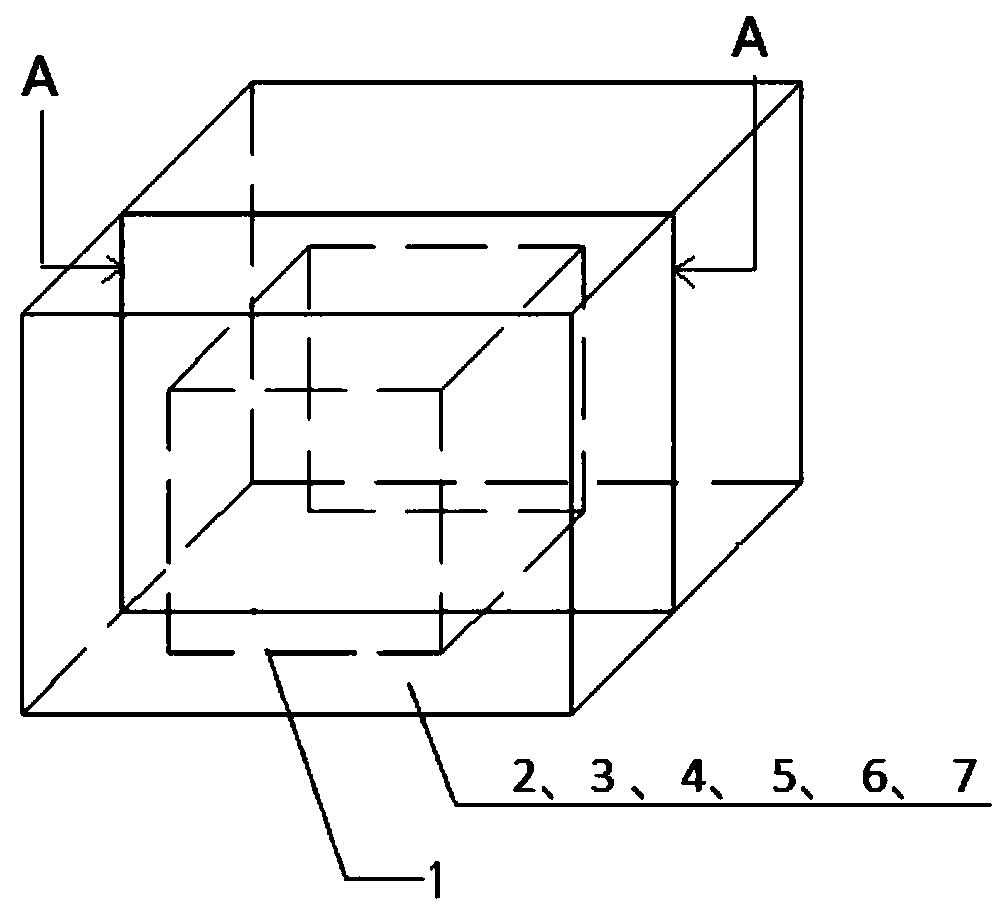

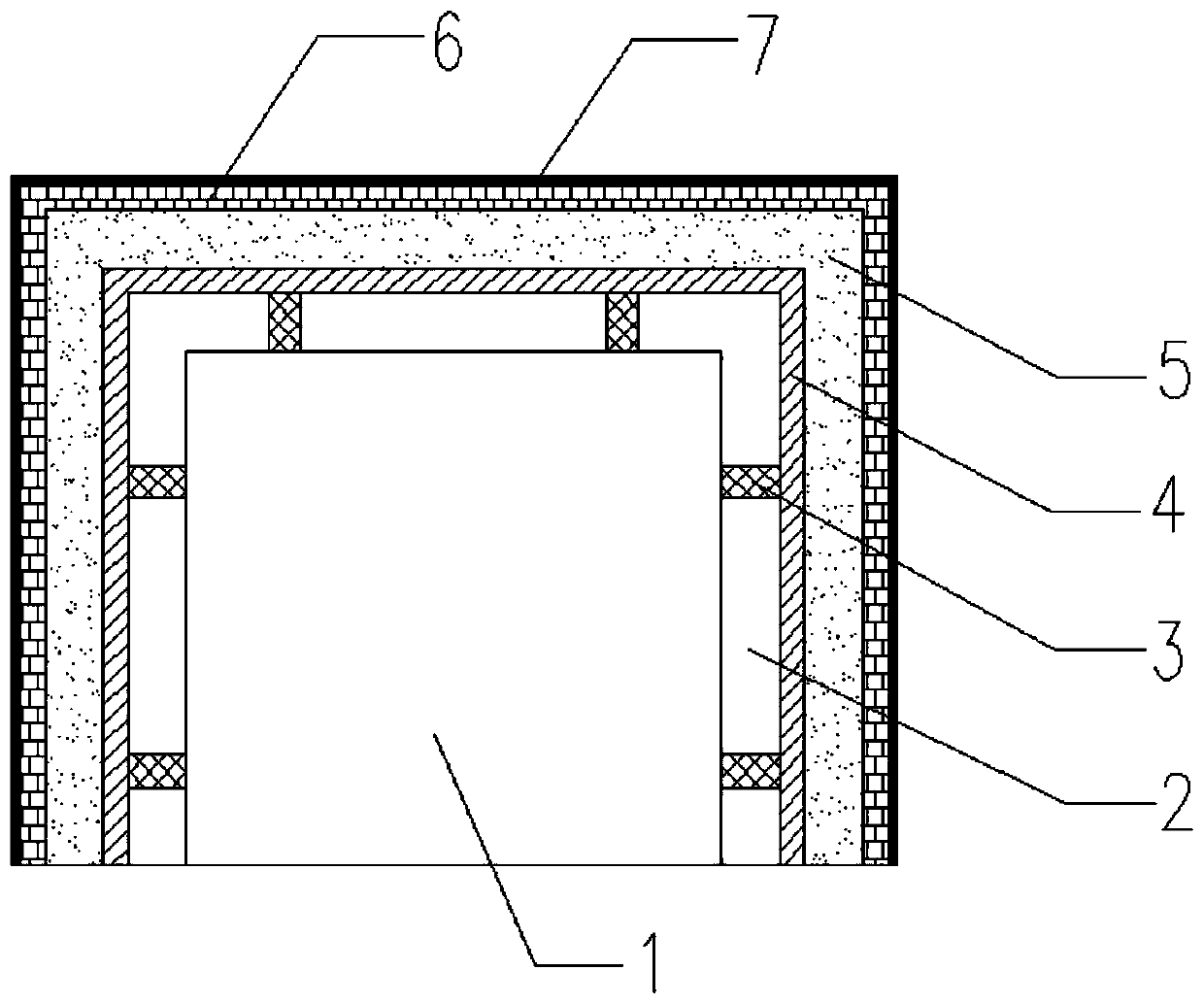

[0038] A passive zero-energy antifreeze technology and method for equipment based on PCM, see figure 1 , 2 As shown, it includes equipment shell, embedded bracket, PCM layer, inner protective layer, heat insulation layer, outer protective layer, and fireproof paint.

[0039] The PCM mentioned in the present invention, that is, phase change material (phase change material), refers to a class of materials that can absorb or release a large amount of energy (ie phase change enthalpy) when a substance undergoes a phase change. Phase change materials use latent heat to store and release heat. They have the characteristics of high heat storage density, compact structure of heat storage devices, basically unchanged temperature during the phase change process, and easy management. They have great potential for engineering applications.

[0040] The device housing 1 is located at the innermost side; the PCM layer 2 is accommodated in the cavity structure between the device housing 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com