Range hood infrared control method, device, range hood controller and range hood

A range hood and infrared technology, applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of high misjudgment rate, inconvenient operation, misjudgment of voice recognition, etc., to achieve the effect of precise control of air volume and improvement of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

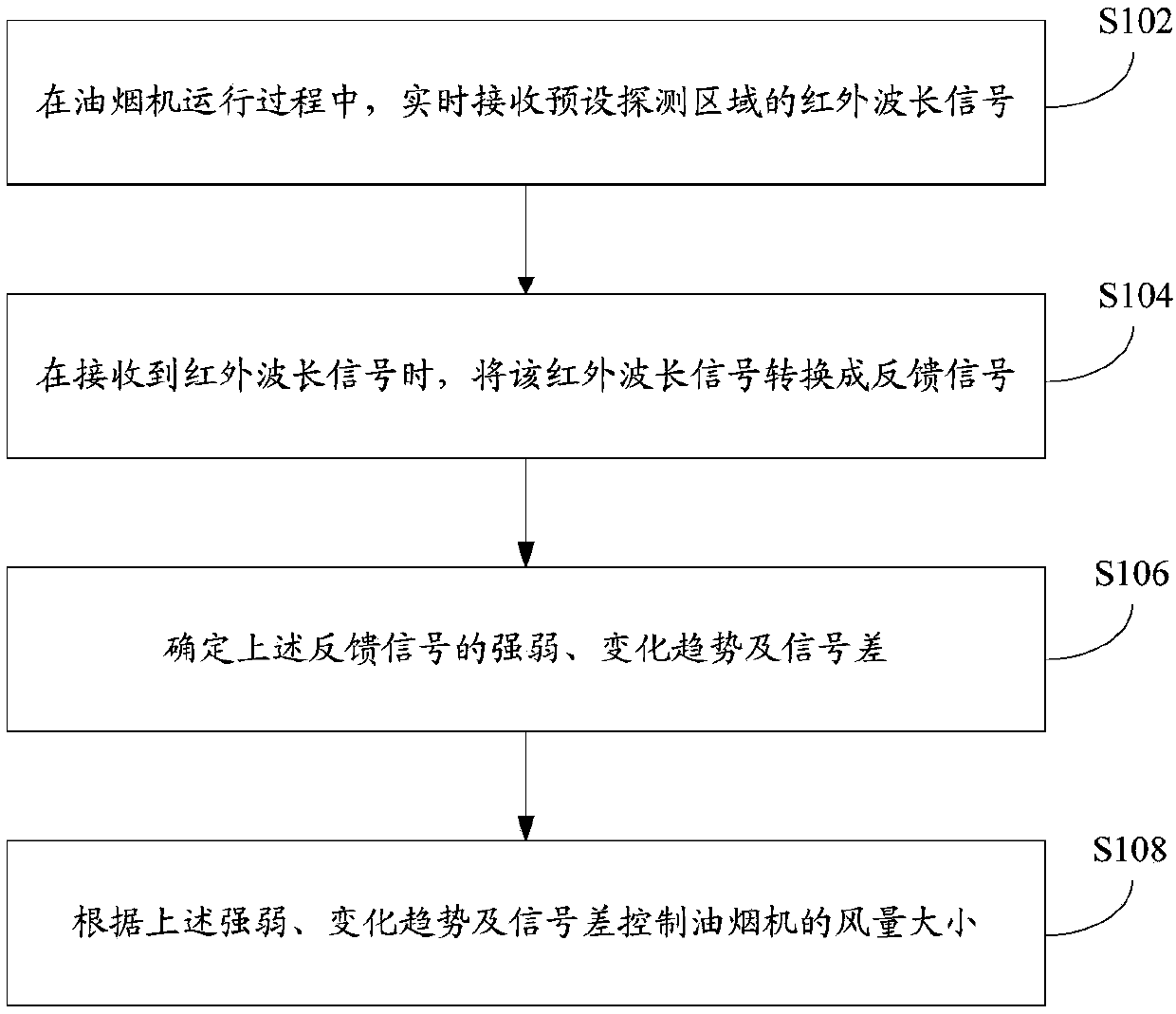

[0031] An embodiment of the present invention provides an infrared control method for range hoods, see figure 1 The flow chart of the infrared control method for the range hood shown, the method includes the following steps:

[0032] Step S102, during the operation of the range hood, receive the infrared wavelength signal of the preset detection area in real time.

[0033] The controller or the main control board of the range hood receives the infrared wavelength signal collected by the infrared control module, and the infrared control module continuously collects the preset detection area in real time during the operation of the range hood. Wherein, the preset detection area is the heating area of the cooker, or the area of cooking utensils such as pots placed on the cooker.

[0034] In this embodiment, the above-mentioned infrared control module adopts a passive infrared sensor module, and the controller or the main control board receives the infrared wavelength signal ...

Embodiment 2

[0065] An embodiment of the present invention provides an infrared control method for a range hood, which is described by taking the conversion of an infrared wavelength signal into a temperature feedback signal as an example.

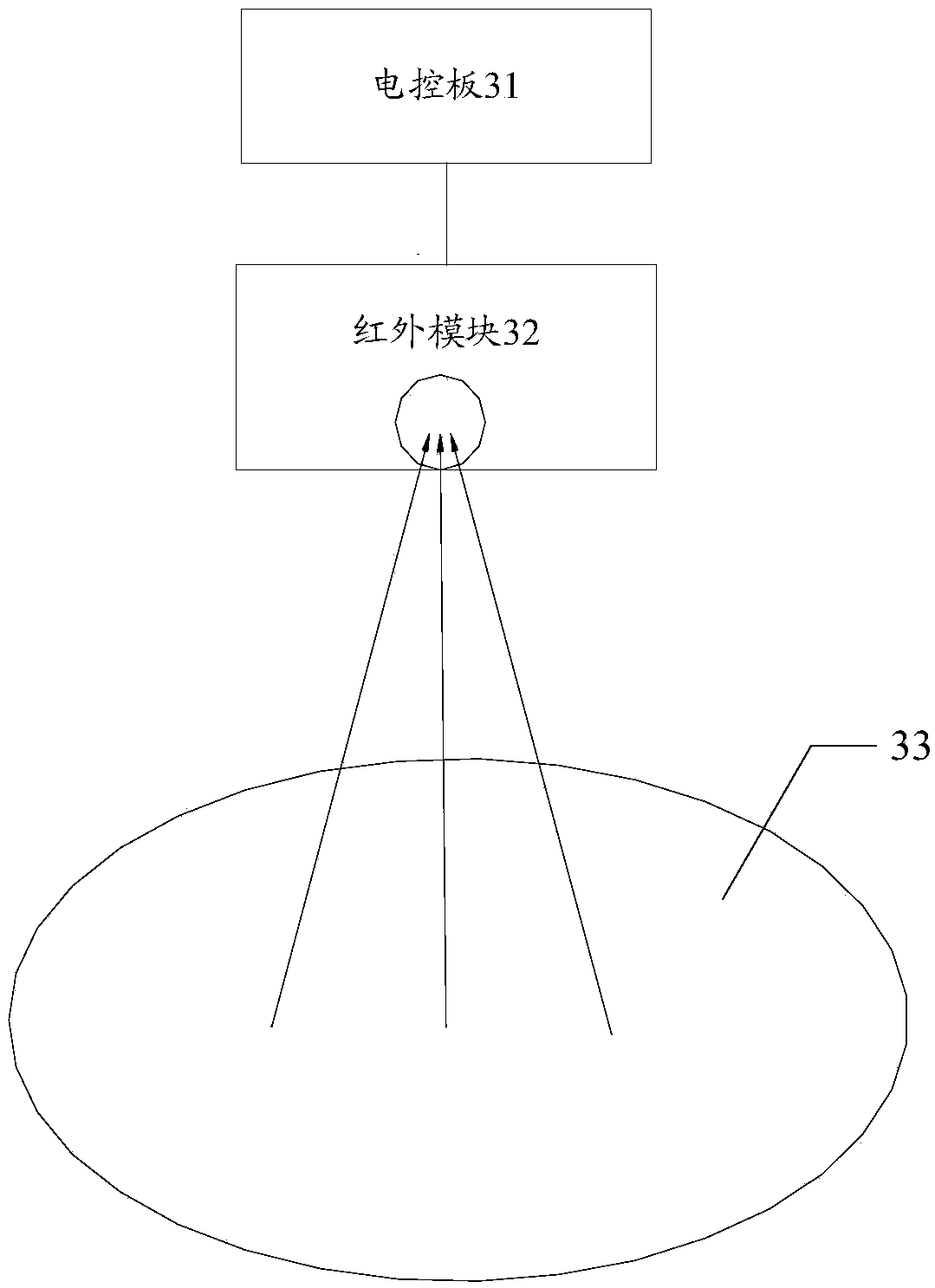

[0066] see image 3 The schematic diagram of the control principle of the range hood is shown, wherein an electric control board 31 and an infrared module 32 are shown, and the infrared module 32 receives infrared waves radiated by a pot 33 . Among them, the infrared module 32 collects the infrared wavelength in the pot 33, and the infrared module converts the wavelength signal into a temperature signal and feeds it back to the electric control board 31 of the range hood. The electric control board performs intelligent control according to the feedback temperature range, temperature change trend and temperature difference. Air volume of range hood.

[0067] The infrared sensor module collects the infrared wavelength in the pot and converts it into a t...

Embodiment 3

[0080] An embodiment of the present invention provides an infrared control device for a range hood, Figure 4 It shows a structural block diagram of an infrared control device for a range hood provided by an embodiment of the present invention, and the device includes:

[0081] The receiving module 41 is used to receive the infrared wavelength signal of the preset detection area in real time during the operation of the range hood;

[0082] A conversion module 42, configured to convert the infrared wavelength signal into a feedback signal when receiving the infrared wavelength signal;

[0083] Determination module 43, is used for determining the strength, change trend and signal difference of feedback signal;

[0084] The control module 44 is used to control the air volume of the range hood according to the strength, change trend and signal difference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com