Reinforcing structure of vehicle body

一种车体、构造的技术,应用在车辆部件、下部结构、上部结构等方向,能够解决无法充分利用带状板材振动衰减能力等问题,达到提高振动衰减能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

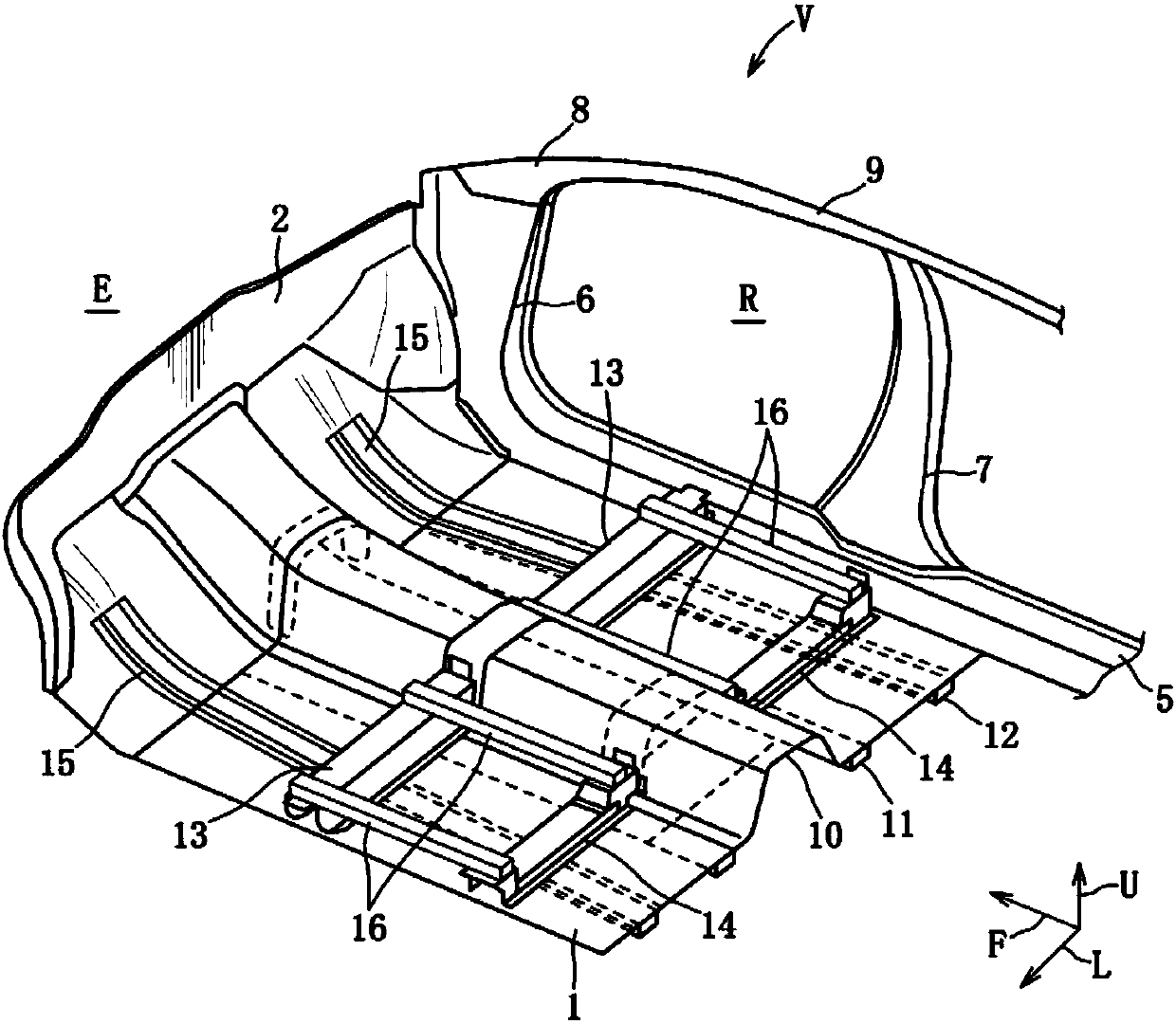

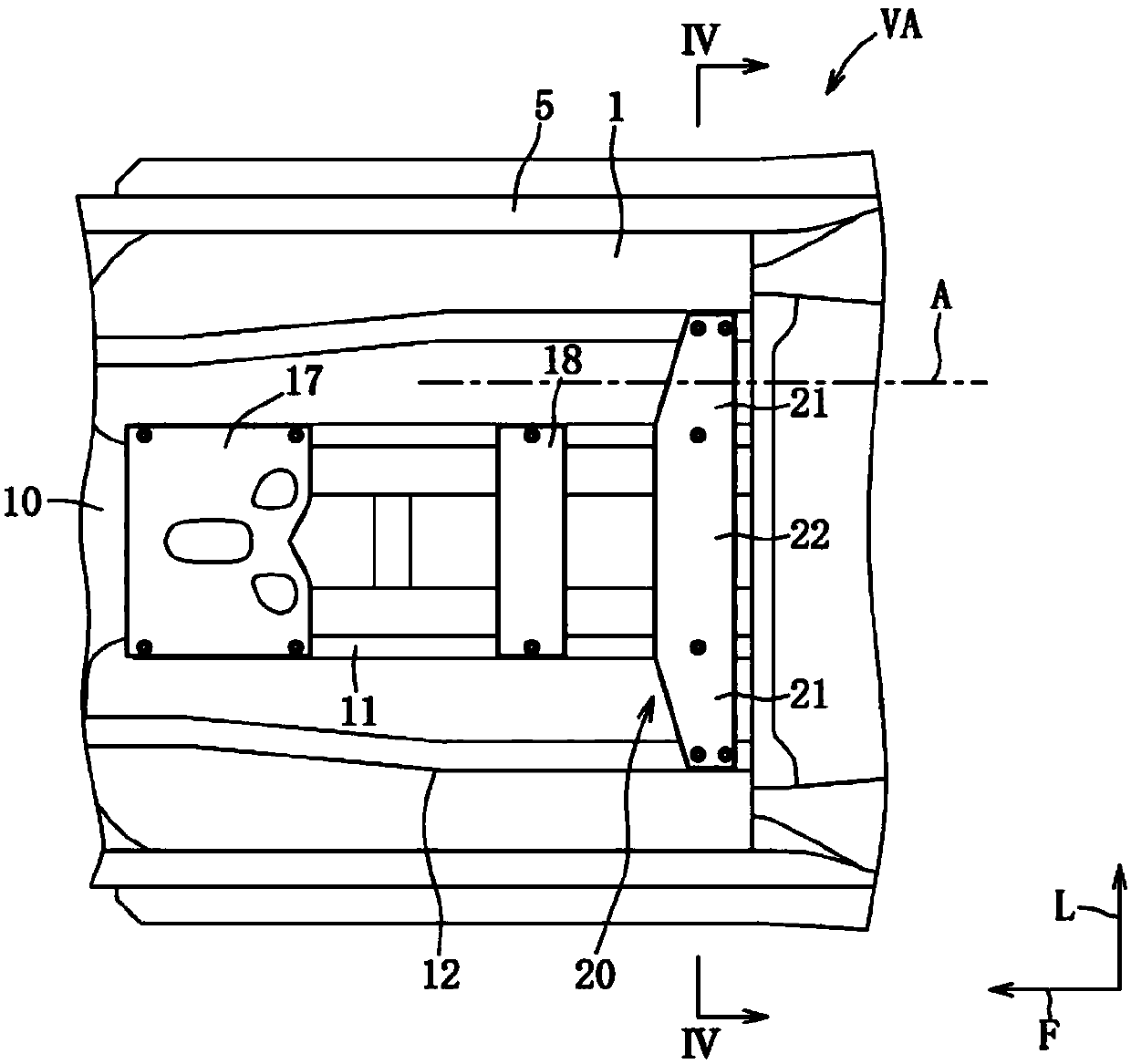

[0063] Below, based on Figure 1 to Figure 7 Example 1 of the present invention will be described.

[0064] First, the overall structure of the vehicle V will be described.

[0065] Such as figure 1 , figure 2 As shown, the vehicle V is composed of a load-bearing body, including: a floor 1 forming the bottom surface of the compartment R; an engine partition 2 standing upward from the front end of the floor 1 and dividing the engine compartment E and the compartment R; A pair of front side frames 3 extend forward from the engine bulkhead 2 ; and a pair of left and right rear side frames 4 extend rearward from the rear end side portion of the floor 1 .

[0066] In addition, this vehicle V includes: a pair of left and right side beams 5 arranged at the left and right ends of the floor 1; a pair of left and right hinge columns 6 extending upward from the front ends of the pair of side beams 5; 7. Extend upward from the middle part of a pair of side beams 5; a pair of front c...

Embodiment 2

[0118] Next based on Figure 8 The 3rd spreader member 20A of Example 2 is demonstrated.

[0119] In addition, the same code|symbol is attached|subjected to the same component as Example 1.

[0120] In Embodiment 1, the left end portion of the belt plate portion 21 is fastened to the bottom wall portion of the floor frame 12 by a pair of front and rear bolts b2 through which a pair of front and rear washers w2 are respectively inserted. In contrast, in Embodiment 2 Among them, the left end portion of the belt plate portion 21A is fastened to the bottom wall portion of the floor frame 12 by a single bolt b2 through which the fixing metal fitting w3 is inserted.

[0121] The third spreader member 20A integrally includes a pair of left and right strap portions 21A and a connection reinforcement portion 22 that connects the inner end portions of the pair of strap portions 21A in the vehicle width direction to each other.

[0122] In addition, since 21 A of 1 pair of strip parts ...

Embodiment 3

[0130] Next based on Figure 9 The 3rd spreader member 20B of Example 3 is demonstrated.

[0131] In addition, the same code|symbol is attached|subjected to the same component as Example 1.

[0132] In Embodiment 1, the front-rear length of the second displacement following portion 21b of the belt plate portion 21 is longer than the front-rear length of the first displacement following portion 21a. In contrast, in Embodiment 3, the belt plate portion 21B has a The front-back length of the 2nd displacement following part 21e is set to the same length as the front-back length of the 1st displacement following part 21d.

[0133] The third spreader member 20B integrally includes a pair of right and left rectangular strip portions 21B and a connection reinforcement portion 22 that connects the inner end portions of the pair of strip portions 21B in the vehicle width direction to each other.

[0134] In addition, since one pair of strip part 21B has a left-right symmetrical struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com