A kind of magnetic compound polymer plastic alloy material and preparation method thereof

A magnetic compound and plastic alloy technology, applied in the field of organic materials, can solve the problem of weak vibration damping function of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

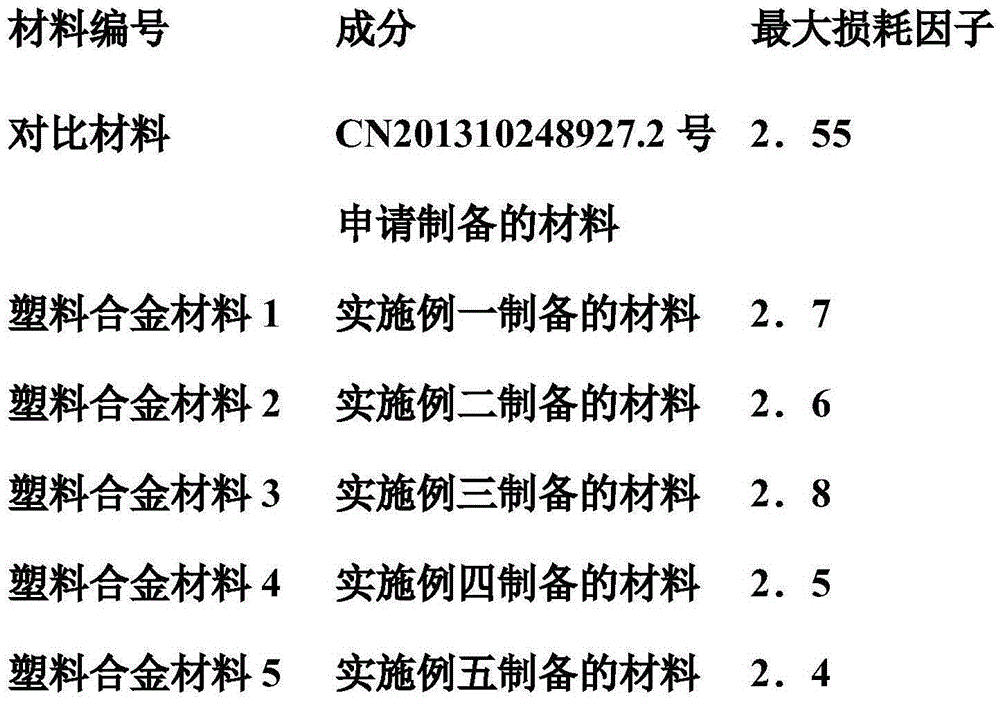

Examples

Embodiment 1

[0028] The magnetic compound polymer plastic alloy material of the present invention, its preparation method is as follows:

[0029] 1) Preparation of niobium-manganese complex oxides

[0030] Raw materials by weight percentage: ZnO3%, MnO30%, TiO 2 6%, C a CO 3 0.04wt%, Nb 2 o 5 0.03wt%, SnO 2 0.03wt%, Co 2 o 3 0.01wt%, the rest is Fe 2 o 3 For batching, the purity of each raw material is greater than 99.9%; the raw materials are mixed and crushed in a sand mill, and then the powder is dried at 120°C, and then sieved after drying with a screen of 180 mesh, and then in the Pre-fired at 870°C for 70 minutes, then pulverized and ground to obtain niobium-manganese complex oxide powder with a particle size of 130-150 microns;

[0031] 2) Preparation of blast furnace slag

[0032] Get the blast furnace slag of above-mentioned composition, grind into particle diameter and be the blast furnace slag powder of 130-150 microns, standby;

[0033] 3) Preparation of BF slag nio...

Embodiment 2

[0038] The magnetic compound polymer plastic alloy material of the present invention, its preparation method is as follows:

[0039] 1) Preparation of niobium-manganese complex oxides

[0040] Raw materials by weight percentage: ZnO13%, MnO40%, TiO 2 8%, CaCO 3 0.06wt%, Nb 2 o 5 0.07wt%, SnO 2 0.05wt%, Co 2 o 3 0.03wt%, the rest is Fe 2 o 3 For batching, the purity of each raw material is greater than 99.9%; the raw materials are mixed and crushed in a sand mill, and then the powder is dried at 130°C, and then sieved after drying with a sieve of 220 mesh, and then in the Pre-fired at 900°C for 80 minutes, crushed and ground to obtain niobium-manganese complex oxide powder with a particle size of 130-150 microns;

[0041] 2) Preparation of blast furnace slag

[0042] Get the blast furnace slag of above-mentioned composition, grind into particle diameter and be the blast furnace slag powder of 130-150 microns, standby;

[0043] 3) Preparation of BF slag niobium manganes...

Embodiment 3

[0048] The magnetic compound polymer plastic alloy material of the present invention, its preparation method is as follows:

[0049] 1) Preparation of niobium-manganese complex oxides

[0050] Raw materials by weight percentage: ZnO8%, MnO35%, TiO 2 7%, CaCO 3 0.05wt%, Nb 2 o 5 0.05wt%, SnO 2 0.04wt%, Co 2 o 3 0.02wt%, the rest is Fe 2 o 3 For batching, the purity of each raw material is greater than 99.9%; the raw materials are mixed and crushed in a sand mill, and then the powder is dried at 125 ° C, and then sieved after drying, the screen is 200 mesh, and then in the Pre-fired at 880°C for 75 minutes, crushed and ground to obtain niobium-manganese complex oxide powder with a particle size of 130-150 microns;

[0051] 2) Preparation of blast furnace slag

[0052] Get the blast furnace slag of above-mentioned composition, grind into particle diameter and be the blast furnace slag powder of 130-150 microns, standby;

[0053] 3) Preparation of BF slag niobium mangan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com