A kind of preparation method of tannic acid modified white carbon black reinforced styrene-butadiene rubber

A technology of styrene-butadiene rubber and white carbon black is applied in the field of preparation of tannic acid-modified silica-reinforced styrene-butadiene rubber, which can solve the adverse effects of rubber and metal skeleton material adhesion, humidity sensitivity, and adverse effects on the quality of vulcanized rubber, etc. problems, to shorten the vulcanization induction period, improve the dispersion, and shorten the vulcanization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

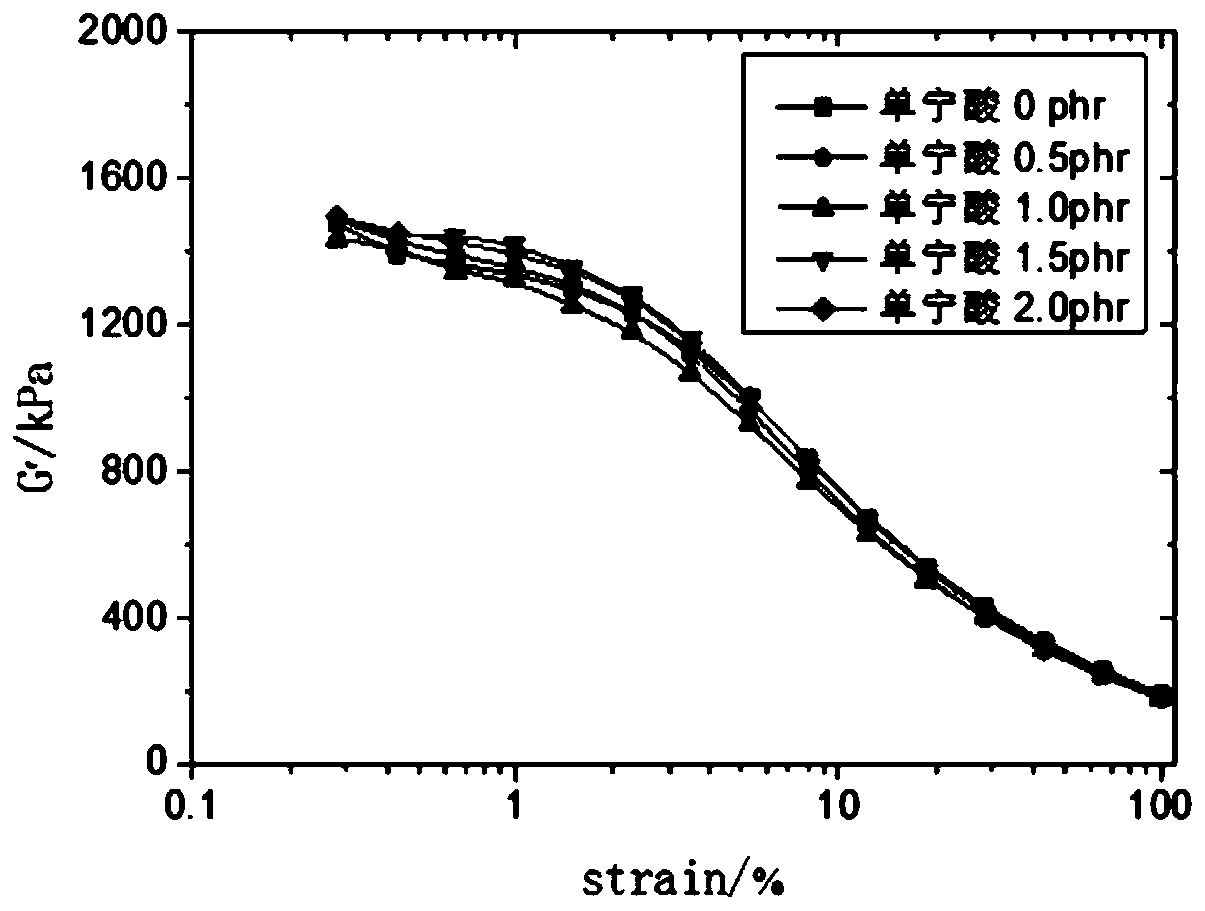

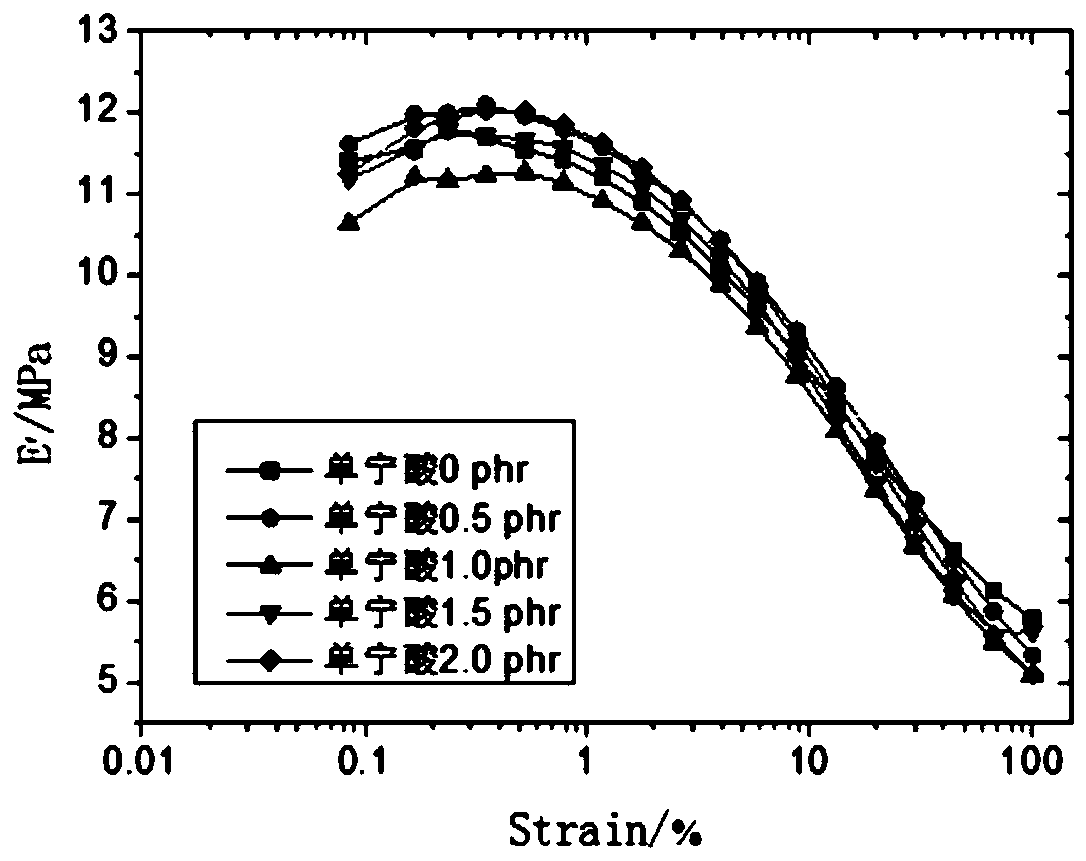

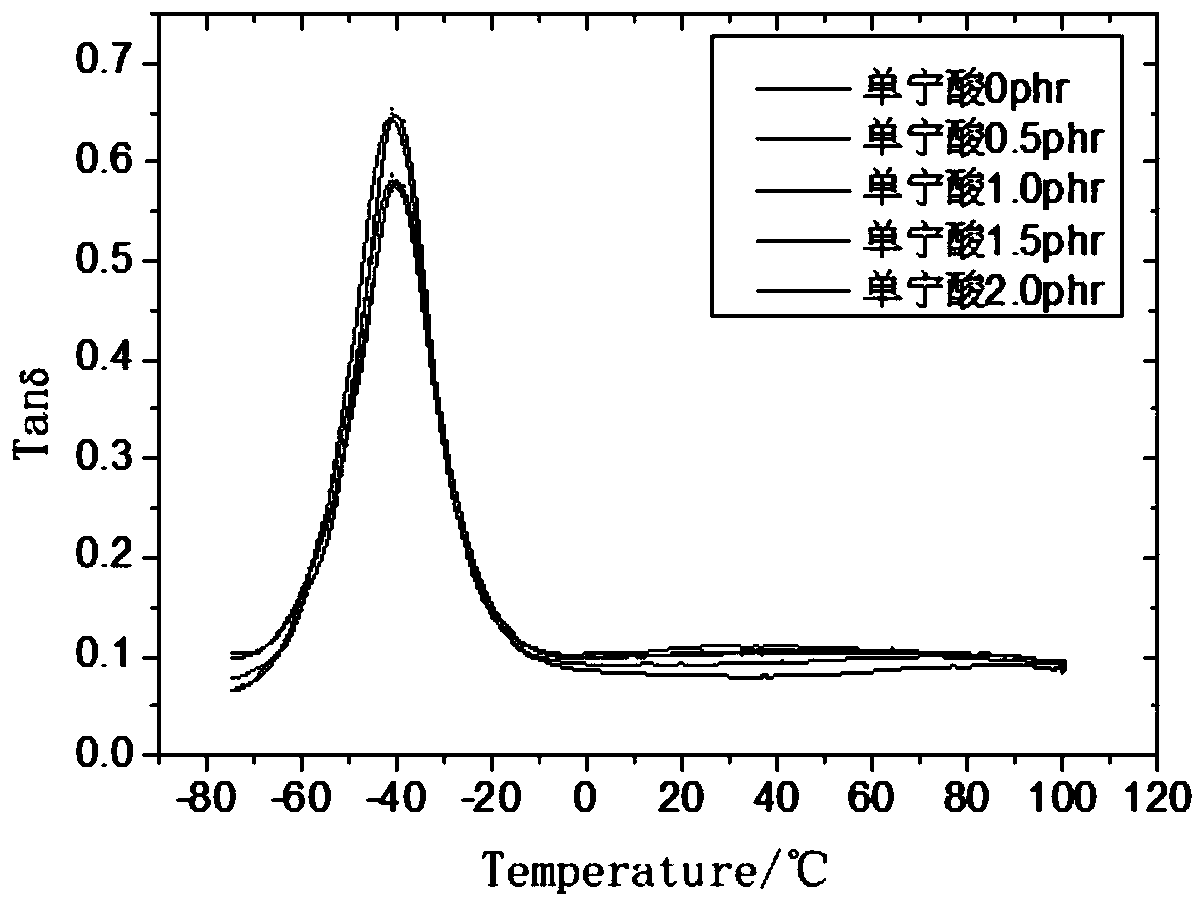

[0022] This embodiment provides a kind of preparation method of tannic acid modified silica reinforced styrene-butadiene rubber, comprising the following steps:

[0023] After placing 75 parts by weight of SBR1502 and 25 parts by weight of butadiene rubber in an internal mixer for banburying for 3 minutes, add 40 parts by weight of white carbon black, 0.5 parts by weight of tannic acid, 3 parts by weight of zinc oxide, 1 part by weight of stearic acid; after mixing evenly, discharge at 90°C, cool for later use; put the rubber material obtained in the first step into the open mill, and add 2 parts by weight of accelerator CZ, 0.5 parts by weight of DPG and 2 parts by weight of sulfur, after the material is completely eaten, the knife is cut, the film is thinned, the film is removed, and the performance of the vulcanized rubber is tested after parking.

Embodiment 2

[0025] This embodiment provides a kind of preparation method of tannic acid modified silica reinforced styrene-butadiene rubber, comprising the following steps:

[0026] After placing 75 parts by weight of SBR1502 and 25 parts by weight of butadiene rubber in an internal mixer for internal mixing for 3 minutes, add 40 parts by weight of white carbon black, 1 part by weight of tannic acid, 3 parts by weight of zinc oxide, 1 part by weight of stearic acid; after mixing evenly, discharge at 90°C, cool for later use; put the rubber material obtained in the first step into the open mill, and add 2 parts by weight of accelerator CZ, 0.5 parts by weight of DPG and 2 parts by weight of sulfur, after the material is completely eaten, the knife is cut, the film is thinned, the film is removed, and the performance of the vulcanized rubber is tested after parking.

Embodiment 3

[0028] This embodiment provides a kind of preparation method of tannic acid modified silica reinforced styrene-butadiene rubber, comprising the following steps:

[0029] After placing 75 parts by weight of SBR1502 and 25 parts by weight of butadiene rubber in the banbury mixer for 3 minutes, add 40 parts by weight of white carbon black, 1.5 parts by weight of tannic acid, 3 parts by weight of zinc oxide, 1 part by weight of stearic acid; after mixing evenly, discharge at 90°C, cool for later use; put the rubber material obtained in the first step into the open mill, and add 2 parts by weight of accelerator CZ, 0.5 parts by weight of DPG and 2 parts by weight of sulfur, after the material is completely eaten, the knife is cut, the film is thinned, the film is removed, and the performance of the vulcanized rubber is tested after parking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com