Unit-type curtain wall system with glass rib decoration

A glass-ribbed, unitized technology, applied to walls, building components, buildings, etc., can solve the problem of non-detachable lamps and other issues, and achieve the effects of improving lighting aesthetics, reliable connection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

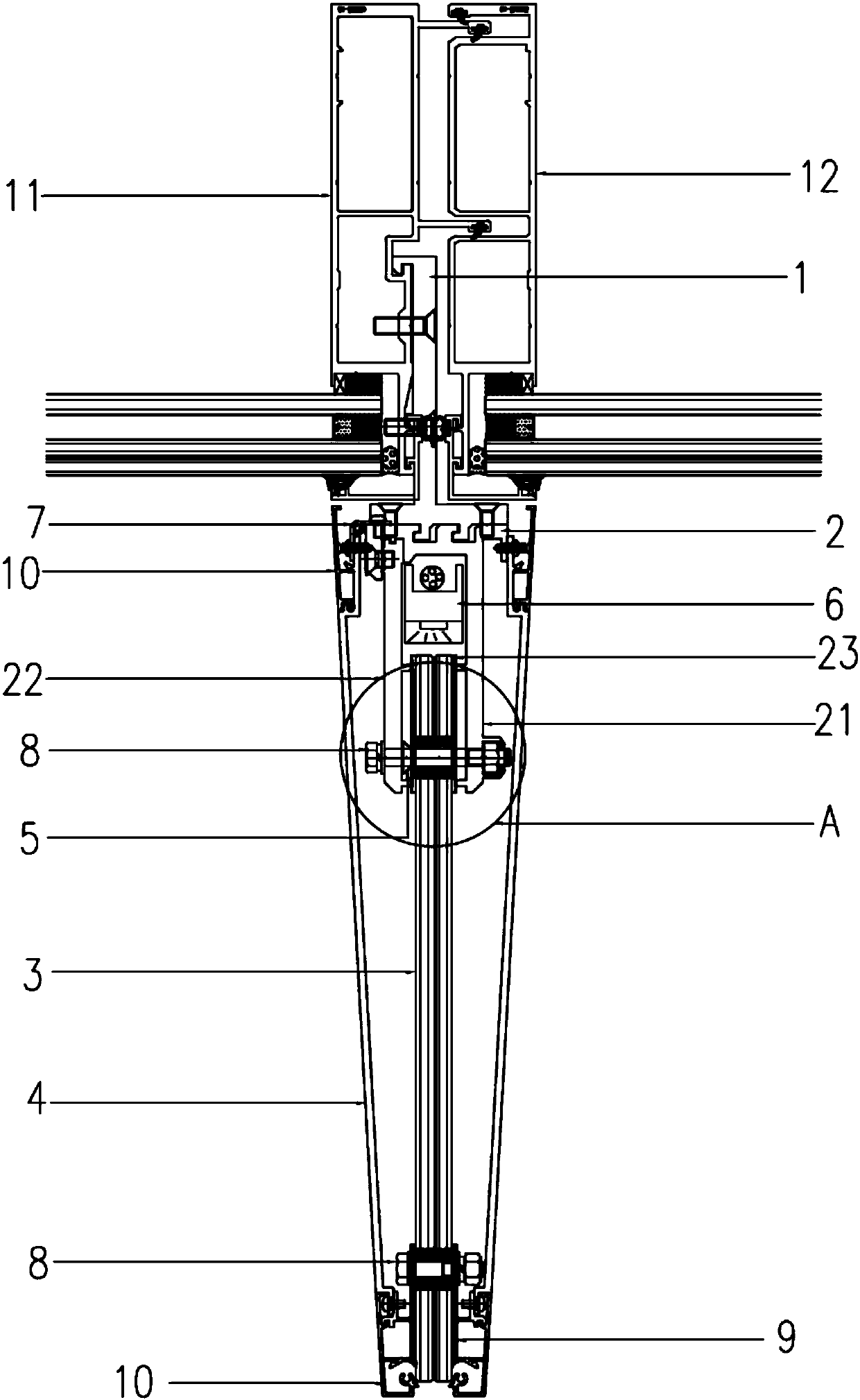

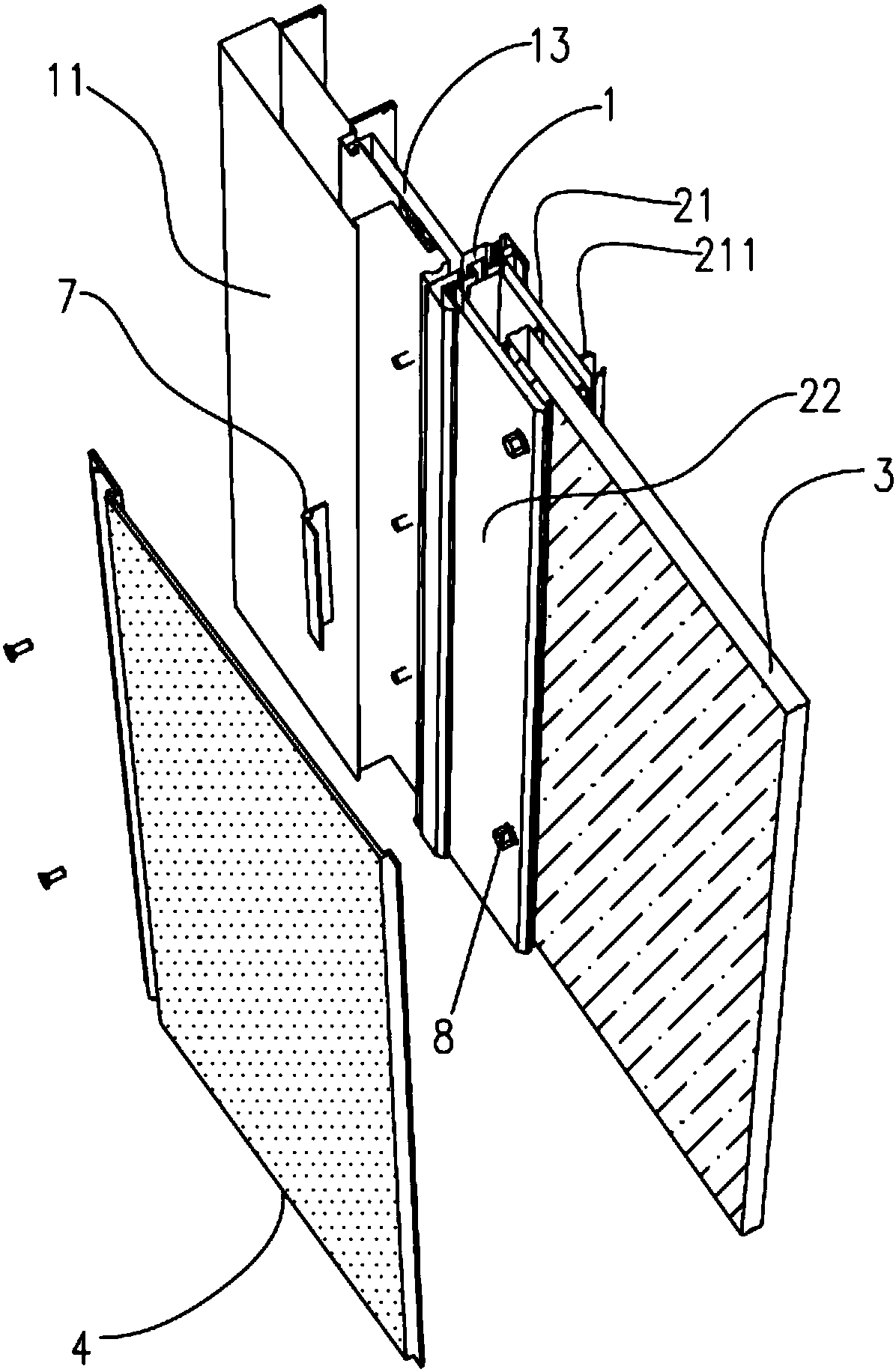

[0023] Such as figure 1 and figure 2 As shown, the unitized curtain wall system with glass rib decoration shown in this embodiment includes a unit column, a connecting support 1 arranged on the unit column, an adapter support 2, a glass rib 3 and an outer cover plate 4, and the turning The end surface of the connection support 2 is engaged with the end surface of the connection support 1, and the transfer support 2 is provided with two first clamping arm ends 21 and a second clamping arm extending outward to form a U-shaped notch 20. end 22, the second clamping arm end 22 is detachably arranged on the transfer support 2, one end of the glass rib 3 is inserted into the U-shaped notch 20 and is fixedly connected with the first clamping arm 21 end; the glass rib 3 is connected with the transfer A lamp 6 is arranged between the supports 2; an outer cover 4 is provided on both sides of the glass rib 3 to cover the glass rib 3, and one end of the outer cover 4 placed on the side o...

Embodiment 2

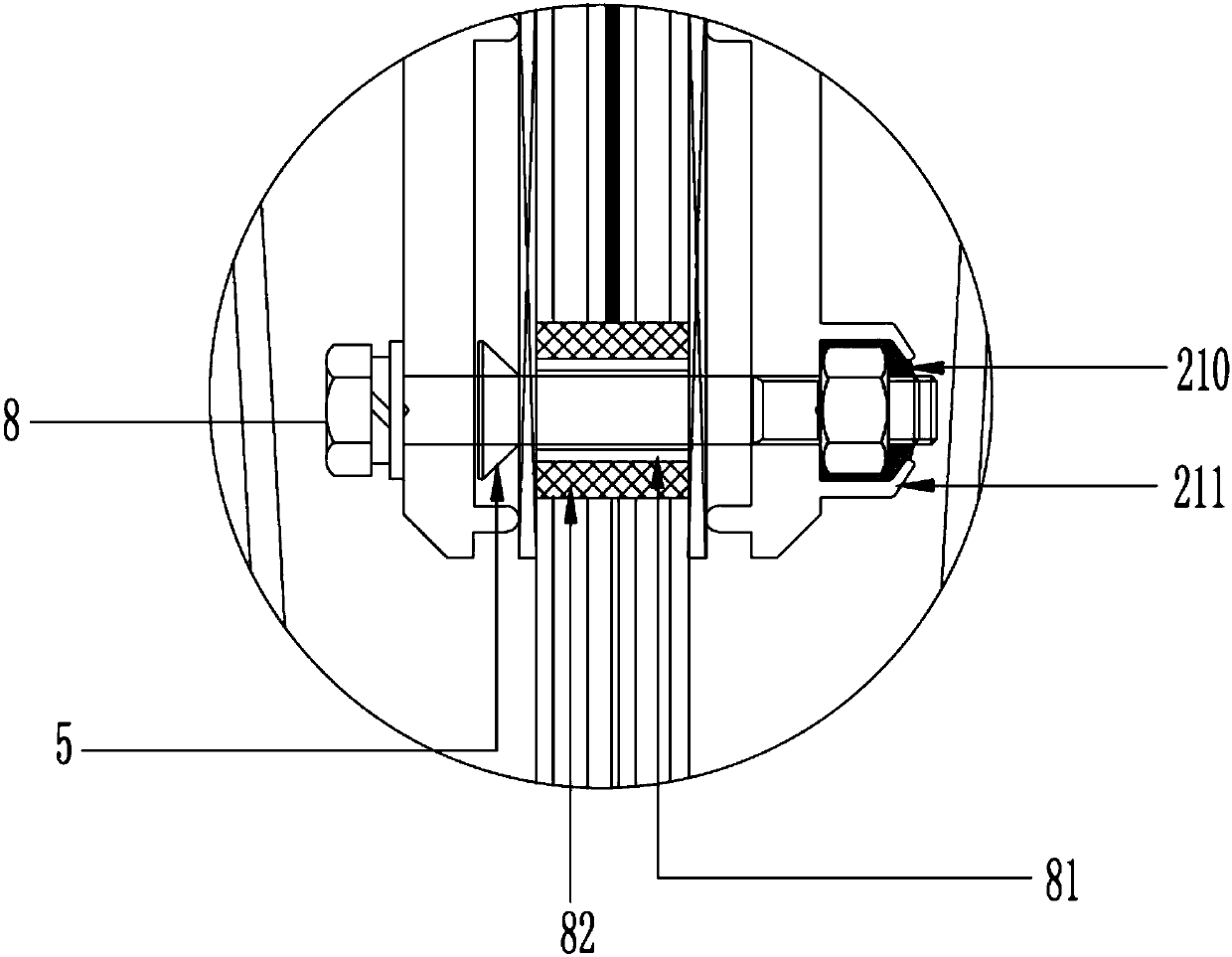

[0025] Such as Figure 1 to Figure 4 As shown, the unitized curtain wall system with glass rib decoration shown in this embodiment includes a unit column, a connecting support 1 arranged on the unit column, an adapter support 2, a glass rib 3 and an outer cover plate 4 (aluminum Alloy outer cover plate), the end surface of the transfer support 2 is engaged with the end surface of the connection support 1 and fixed with screws, and the transfer support 2 is provided with two first clips extending outward to form a U-shaped notch 20 The holding arm end 21 and the second clamping arm end 22, the first clamping arm end 21 and the transfer support 2 are integrally formed, and the second clamping arm end 22 is arranged on the transfer support by means of engagement 2 and fixed with screws, one end of the glass rib 3 is inserted into the U-shaped notch 20 and is fixedly connected with the first clamping arm end 21 through the countersunk bolt assembly 5, and the countersunk bolt asse...

Embodiment 3

[0033] A method for replacing lamps in the unitized curtain wall system with glass rib decoration described in Embodiment 2, comprising the following steps:

[0034] S1. First remove the decorative strips 10 at both ends of the outer cover plate 4 placed on the side of the second clamping arm end;

[0035] S2, then take off the screws fixing the outer cover plate 4 and the connector;

[0036] S3, then rotate outwards to open the outer cover 4;

[0037] S4. Take off the screws fixing the second clamping arm end 22 and the transfer support 2;

[0038] S5, take off the bolt assembly 8 connecting the first clamping arm end 21, the glass rib 3 and the first clamping arm end 22;

[0039] S6. Pull out the second clamping arm end 21 to separate the second clamping arm end 21 from the transfer support 2;

[0040] S7, and then replace the lamp 6;

[0041] S8. After the lamp 6 is replaced, all the disassembled components are put back in order.

[0042] As in other embodiments, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com