Clamping assembly and method for single fuel element under transient irradiation test conditions

A fuel element and clamping assembly technology, applied in the field of irradiation, can solve the problems of maintaining a single fuel element, difficult to maintain a single fuel element, etc., and achieve the effects of keeping fixed, stable, overall strength and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

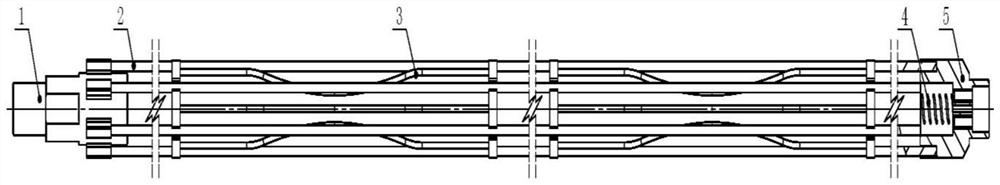

[0039] Such as Figure 1 to Figure 6 The shown clamping assembly for a single fuel element under transient irradiation test conditions includes an upper fixed ring 1, a central grid 3, and a lower fixed ring 5 distributed in sequence. The upper fixed ring 1, the central grid The frame 3 and the lower fixing ring 5 are fixed by several support rods 2; the central grid 3 is used to clamp a single fuel element;

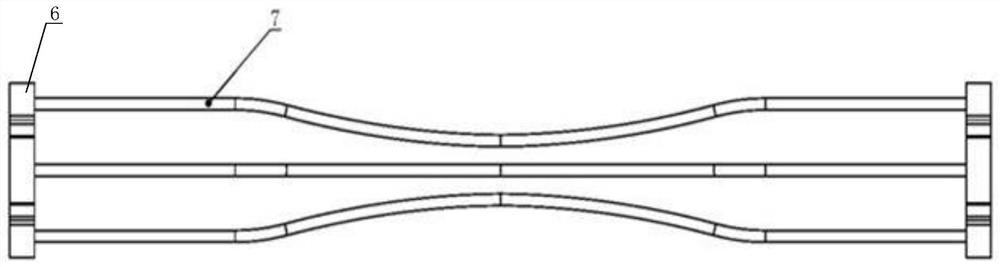

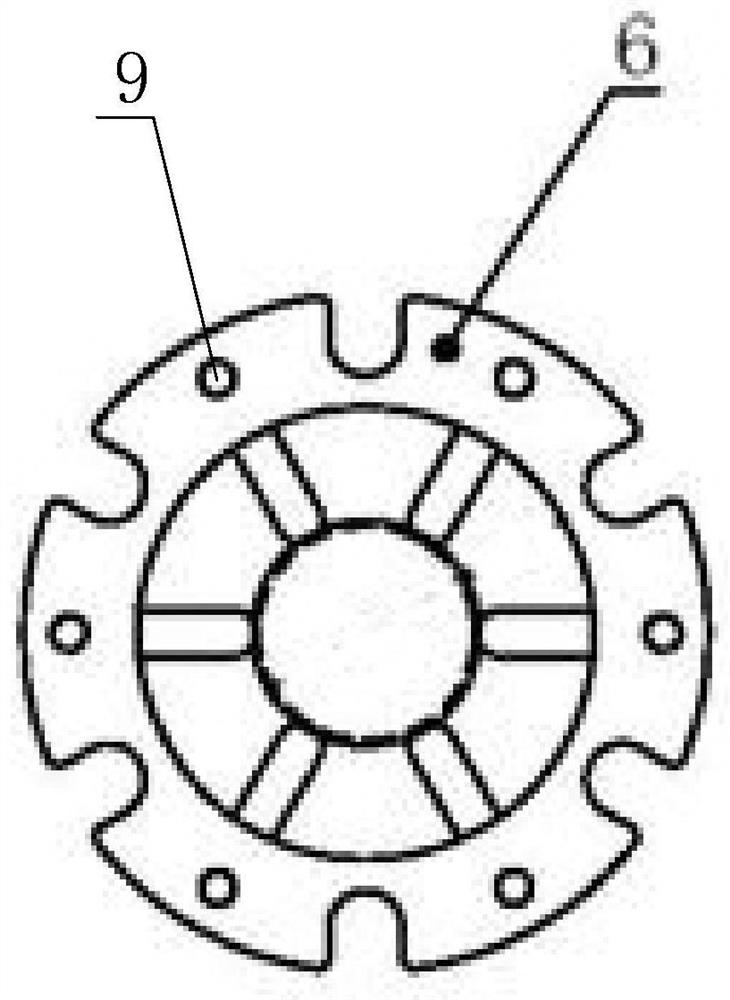

[0040]Preferably, the central grid 3 includes two central fixed rings 6 facing each other, and a number of annularly distributed elastic rods 7 are arranged between the two central fixed rings 6, and the elastic rods 7 have a direction toward the central fixed ring 6 A curved section that is concave in the direction of the axis. Several supporting rods 2 are distributed in a ring, and the circumferences of the upper fixing ring 1 and the lower fixing ring 5 are provided with some fixing holes 8 for fixing the ends of the supporting rods 2, and the center fixing ring 6 i...

Embodiment 2

[0047] The upper fixed ring 1, the lower fixed ring 5 and the center grid 3 are connected by the support rod 2. During assembly, the elastic member 4 is welded to the lower fixed ring 5, and then the support rod 2 is inserted into the fixing hole of the lower fixed ring 5, and then put into the center after welding. Grid 3, the whole assembly is put into two center grids 3, keep a certain distance between them, the place where the support rod 2 contacts the center fixing ring 6 of the center grid 3 is spot welded, and finally the support rod 2 is inserted into the upper fixing ring 1's fixing hole is welded. The whole assembly is connected with each part through the support rod 2, and the contact parts are welded to ensure the overall strength of the grid. The center grid 3 is welded on the support rod 2, and the fuel element is clamped by the elastic rod 7. The end of the fuel element is in contact with the elastic member 4 to avoid damage to the fuel element due to hard con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com