Tyre for vehicle wheels

A technology of tires and wheels, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc., and can solve problems such as reducing tire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

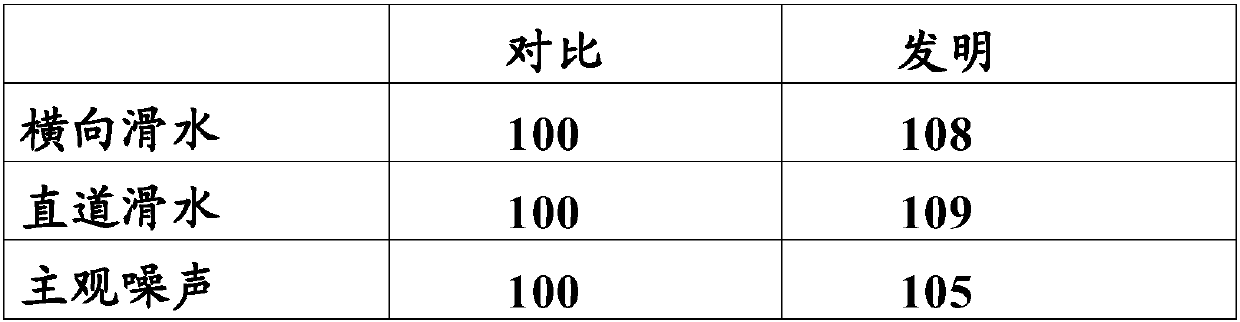

Examples

Embodiment Construction

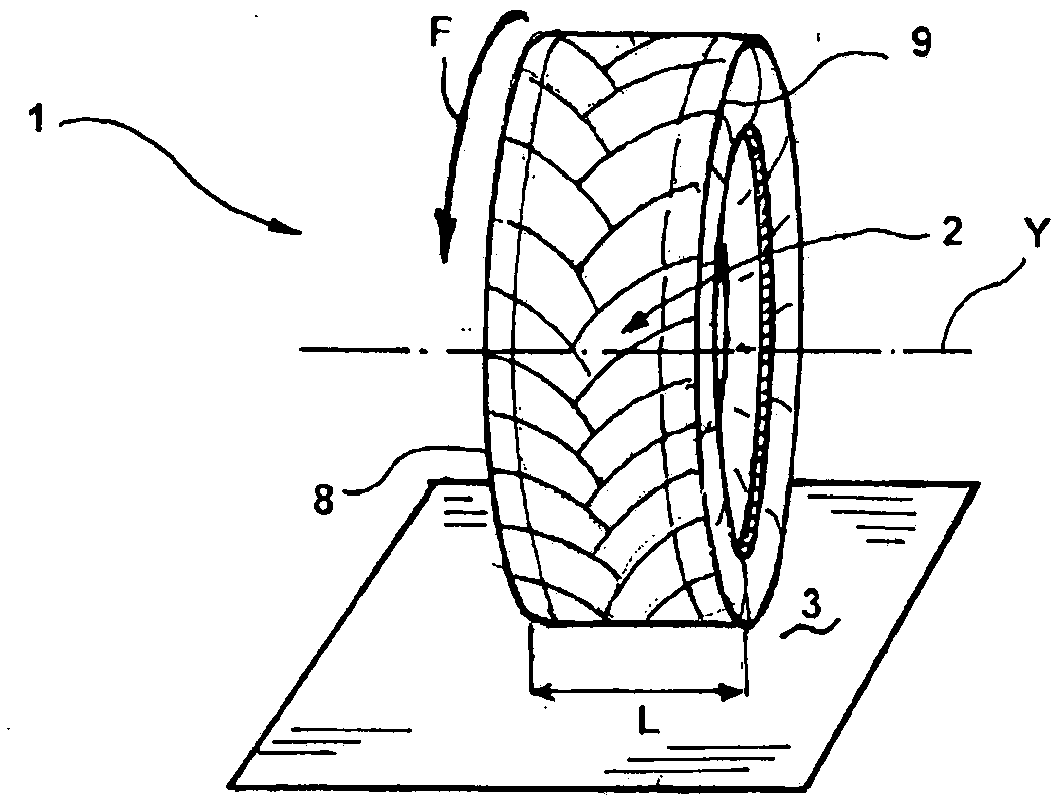

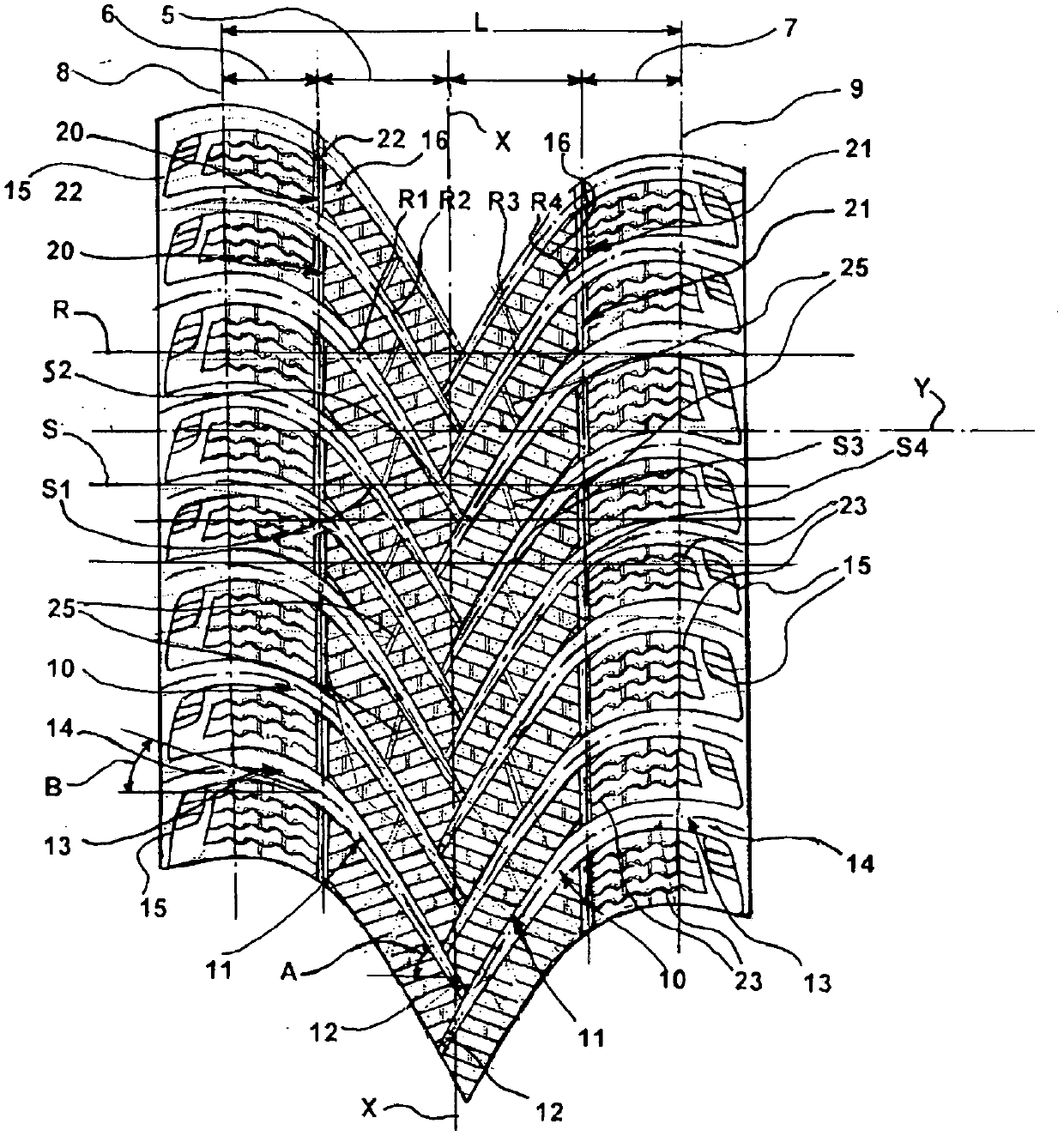

[0065] Referring to the drawings, a tire for vehicle wheels manufactured according to the present invention is generally indicated by reference numeral 1 .

[0066] The tire 1 has a conventional form, substantially toroidal, extending around an axis of rotation defining an axial direction Y of the tyre, and through which an equatorial plane X extends perpendicularly to said axis of rotation.

[0067] The tire 1 is a winter tire and comprises a tire structure, which is conventional in nature and not illustrated in the drawings, and a tread band 2 arranged radially externally with respect to the tire 1 location, and if figure 1 for contact with the road surface 3 as schematically shown in .

[0068] Preferably, tire 1 has a nominal section width of between about 155 mm and about 235 mm. Preferably, said nominal cross-sectional width is less than or equal to about 215 mm. Preferably, the tire 1 has a rim diameter of between 14 inches and 17 inches.

[0069] An effective width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com