A processing device for processing anti-pinch grooves of ultra-thin diamond cutting discs

A diamond cutting and processing device technology, applied in the field of electrolytic grinding, to achieve the effect of good double-sided symmetry, high precision, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

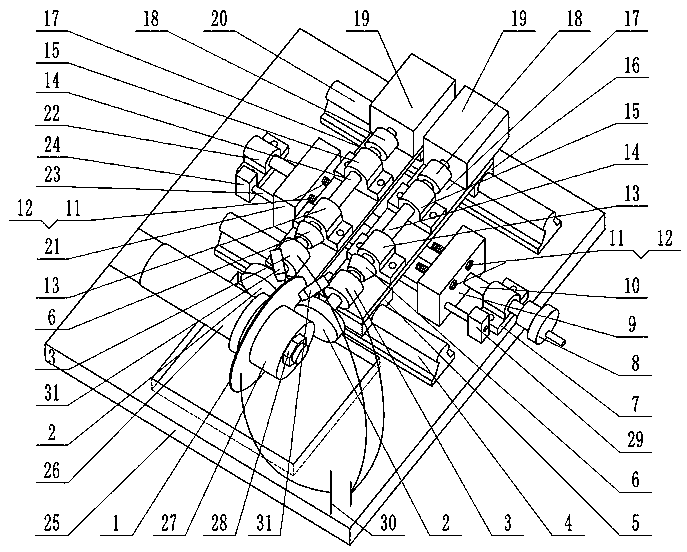

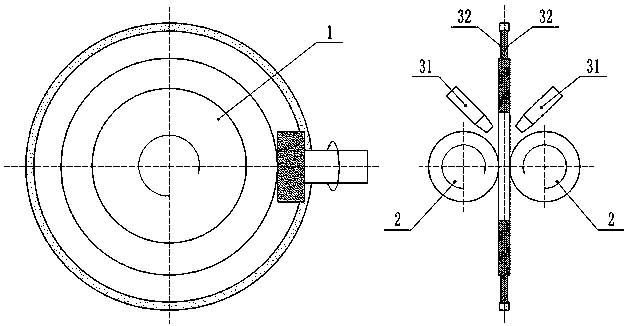

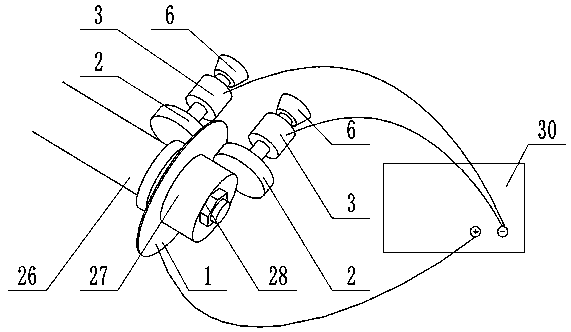

[0035] Combine below Figure 1 to Figure 4The implementation of the present invention is further described in detail: a processing device for processing ultra-thin diamond cutting blade anti-pinch grooves, including a motor 19, a shaft coupling 18, a rotating shaft 14, a bearing-bearing seat assembly 13, a bearing- Bearing housing assembly 15, grinding head chuck 6 and grinding rotation unit of conductive grinding head 2, fixed platform 25, electrolysis power supply 30, nozzle 31 and workpiece containing workpiece 1, rotating spindle 26, chuck body 27, lock nut 28 The clamping unit is characterized in that it also includes a conductive grinding head moving guide unit including a front guide rail 4, a rear guide rail 20, a front slider 5, a rear slider 16, and a slider connecting plate 17, and includes a two-way lead screw 10, a wire Grinding of rod fixing seat 7 and lead screw fixing seat 22, hand wheel 8, left-handed nut seat 21, right-handed nut seat 9, light rod 23, light r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com